-

Posts

1,546 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Rick500

-

-

Okay guys, question asked, answer found, let's move on. Thanks.

-

<searches for the mind bleach>

-

I have a Jet/Performax 16/32... Takes maybe, 15 - 20 seconds per pass. 4 passes will cover the entire surface of both sides.

Really depends on how many times you need to run it through, but time is definitely not excessive.

I'm assuming we're just talking about surfacing here, not removing a lot of material.

If you need to remove a significant amount, say 1/16", it'll take a few passes.

-

I've used the one from StewMac for one and only one fretboard. Then bought the dozuki fret saw from LMI--it cuts *so* much easier. Doesn't have a depth stop though.

-

-

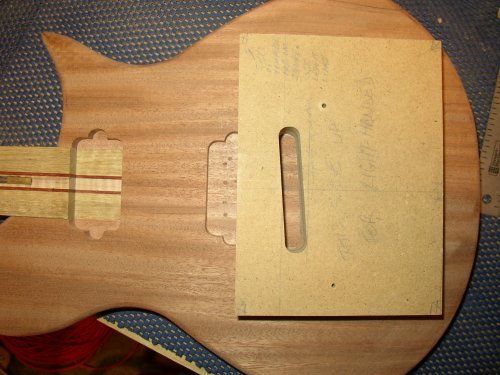

The #6506 one only has the bearing above the cutters (on the router end of the bit), so it's already in the right place to route cavities.

-

-

I have a Porter Cable random orbit ($50 or $60 I believe) and it's been great. I also have a quarter sheet sander similar to the one linked above (but Black & Decker) and I haven't touched it since I got the random orbit sander. It's easier to use, easier to control, does dust control better, and the disks are Velcro backed so they stay put (a problem with the quarter sheet sander).

-

If you want to rout using a drill press you will most likely ruin the drill.

I found this excellent video on YouTube on how to carve a top

From about 4:27 to 7:35 he uses a cutter that looks like a large bit in the drill press. So if a regular router bit would possibly ruin the drill, wouldn't this ruin it too? And if it would, what other machine would you use this cutter in?Yeah, that's Chris's video. He's a member here. Good stuff.

I haven't watched that video in a while, but if I remember correctly, he was using a Safe-T-Planer in the drill press. They take a very, very small bite out of the wood. I have one but I won't use it in my good drill press. I'm not sure how the lateral pressure from a properly set-up Safe-T-Planer compares to a router bit.

-

First, I have no doubt that the Veritas is a better tool. But it's also pricey, and the Stanley can be made to work well.

-

The Stanley ones aren't half bad if you're willing spend an hour or so tuning them up.

-

As for drill presses: I have this one and am extremely pleased with it.

(It does not have the quill lock feature you mentioned, however. But here is an article on how to make the modification yourself. I have not tried this and don't know if it's applicable to the Jet 17" model. In any case, I'd be careful applying a lot of lateral pressure such as you would trying to use a router bit in it.)

-

Nice top!

-

That's true. I have, I think 15, of their guitars, though, and never one problem with a neck in any way in all the 15 years I've been playing their guitars.

-

Don't let it put you off to DIY. Your first one just wasn't going to be perfect.

If it were me, I'd figure out where I went wrong, then do it again.

If it bothers you enough to post about it, you need to fix it.

-

I'd have to go with #1 as well. The others would present ergonomic problems. Points for creativity though.

-

-

Well, SOME of us mods are an okay lot.

-

Now where did you read that?

Does someone named Litch ring a bell??

Does someone named Litch ring a bell??You know, I spent most of an evening a couple years ago reading that whole soap opera. I must admit it was more entertaining than anything on TV.

-

Well, he certainly is happy.

-

I have a flamed maple guitar with a finish that's somewhat similar. I didn't finish it, but I know how it was done: stained black, sanded back down, stained brown, sanded back down, then stained sort of a vintage yellow (then bursted).

The headstock pic is close to the real color. The body pic is kind of washed out.

-

Ooh, quilted maple fretboard. Never considered that. Might be fun.

-

Wow, that's a good deal.

-

Check here. And probably also StewMac.

First Inlay Job Help Please

in Inlays and Finishing Chat

Posted

C'mon guys, let's stick to helping out the OP here.