Quarter

-

Posts

391 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Quarter

-

-

You could try sanding more or all of the veneer off to even / randomize the whole look.

If that doesn't work out, you can always try your hand at a veneer.

Here is a handy link from the tutorial section http://www.projectguitar.com/tut/veneer.htm

Other finishing ideas in the tutorial too http://www.projectguitar.com/tut/tutorial5.htm

-

Link works for me ... search for RIDGID Oscillating Edge/belt Spindle Sander

I have one and its a handy tool for sure.

-

... my solution was to hold one edge flat against my tablesaw table, and glue a strip of hardwood onto the other edge so that it fed through the planer properly. ...

Thats a neat idea, glue on some strait sacrificial edge guide/ runners

-

I wouldn't bet against ash.

-

I agree it's not difficult stuff, but mistakes with electricity are unforgiving, and $50 or $100 isn't a steep price to pay to avoid all danger of electrocution.

Absolutely, and lets not forget about the potential fire danger either.

Kenny ... I have a friend in SD that has a sparky he likes, I'll see if I can get a number for you.

-

Early mornings are your best times for calm conditions, set the alarm and be ready to spray come sunrise. Also, the night before, it is helpful to water down the general area you are going to be working.

-

To get perspex to glow, you can imbed an led in the plastic, but the surface needs to have a rough texture for it to glow, smooth surfaces will not glow.

If you want a smooth surface to glow, you need to back light it and use colored perspex. Not sure if you would have enough open room in the cavity to properly back light it.

-

Tru Oil is really more like a varnish than a strait oil. I've used a lot of it and its one of my all time favorite finishes.

I've not used it over a pigmented stain, no problem with dyes though. You could test on a piece of scrap first and or do a quick shellac sealer coat over the top first.

-

That came out nice, thanks for the info

-

If you do install the bushings, you can fashion a simple puller to take them back out.

Something like this StewMac puller, but with just some all thread into the bushing. You can use a short section of plastic pipe and washer, blocks of wood, etc.

-

A glue that has a moisture content will swell wood to a minor degree, but its very minor and would shrink back when dry.

Your not seeing the gaps because ebony really hides gaps well. With black glue and a bit of dust and sanding, its very hard to see the lines.

-

There are pearl pigments and powders that you could try mixing in with the epoxy.

Recon Stone has some good looking pearls and metallics and there is also a product called Pearl Ex thats interesting.

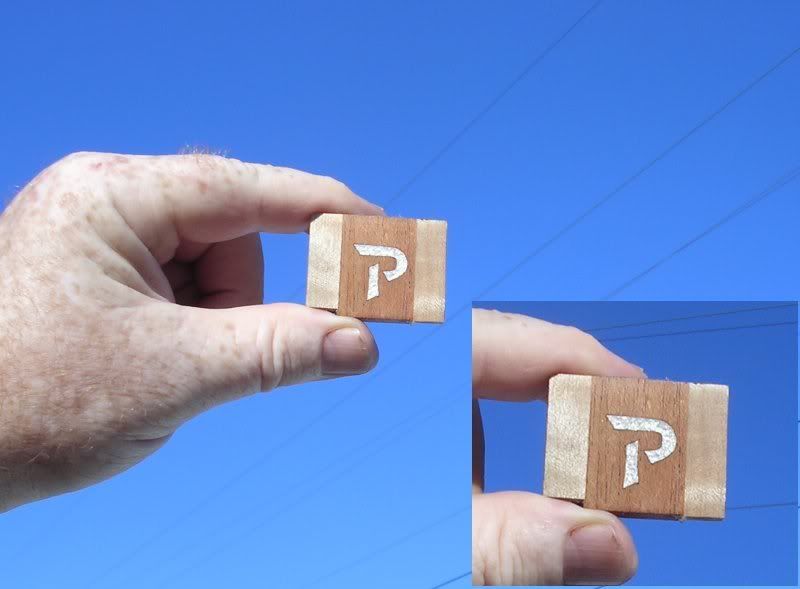

Here is a test piece I was playing with using some Pearl Ex Macro Pearl mixed in epoxy. Its not maple or filler around pearl, but it gives you an idea.

.

-

Thanks zyonsdream ... great suggestions and good grounded advice.

... Drying and aclimating costs really make strong case for allowing yourself a good deal of time(meaning have a stock of ready wood) so you can have wood ready to use while you allow a back stock plenty of time to get ready for use.Absolutely, I couldn't agree more. I normally buy dry wood and rack it up for future use, but once in a while I come across a piece I like that is not dry. Usually I'll pass, but have increasingly been considering drying my own.

In a perfect world, I could run it through a kiln, then rack it up for future use. Problem is that its hard to justify building a kiln for just the odd piece here and there.

I'm going to explore the topic some more and may try my hand at building a smaller scale kiln. For a one off piece, its not a good investment, but as a learning tool and possible future use, it has merits.

Right now, a solar type seems the most economically sensible, but the vacuum types appeal to me due to the lower temps needed.

-

Thanks Rich ... good food for thought

-

What about flame maple? Will the end grain there absorb the slurry? If not, then it looks like I am set.

It shouldn't as the first wet coat, before you start sanding, should be enough to seal it up. Wouldn't hurt to do a second coat of oil before you start the sanding. That would make sure the maple is sealed good.

-

I wouldn't worry about the walnut slurry staining the maple, or at least I've not had trouble with my walnut / maple and mahogany / maple laminates.

Any that gets on top of the maple gets sanded off.

Alder is a closed grain and does not need filling like mahogany, walnut, etc.

-

Thanks all for the input, it is much appreciated.

A quick Google turns up some small inexpensive dehumidifiers that would be a great size for a closet or other small area.

Slow going is fine for me. This piece has been air drying for almost 2 years, but at the rate its going, I just don't want to wait another year

-

I was wondering if any have built their own small scale wood kiln.

I've got a 8/4 piece of cocobolo that I'd like to accelerate the drying on, its down around 15% - 16% right now.

Web searches come up with a lot of interesting kiln ideas, solar, dehumidification, and vacuum systems, but all are fairly large scale.

I had the thought of maybe just building a suitable sized air tight chamber, or maybe a vac bag, and using a vacuum pump or venturi to accelerate the drying a bit.

It doesn't need to be super fast, just that I'd rather not wait another year or more to use it

Any other ideas for a simple and easy solution for small quantitys?

-

Tru Oil does look great on swamp ash and has a great feel to it too.

-

Is Tru-Oil a tung oil?

No, True Oil is a modified / polymerized linseed oil based varnish. True / pure tung oil is an extract from the tung tree.

-

Thanks Old Rocker

... Looking forward to seeing your build

... Looking forward to seeing your build

-

... In fact, Quarter, do you mind if I copy them for my daughter's tele project? ...

Sure, but its not an original idea of mine, but something I saw somewhere in my web surfing, probably from here.

The 9/32 tubing seems to be a pretty standard size carried by hobby shops, comes in brass too.

The only thing I'd advise is to keep your paper and wood blown clean and often while sanding as the aluminum dust can build up in the grain if you are not careful. I've not tried it on maple or other light colored woods, so some testing on scrap first would be recommended.

-

I'm a major Tru Oil fan, I use it almost exclusively on the steels I build. And yes, you can do a nice level gloss with Tru Oil.

More Tru Oil info in this thread http://projectguitar.ibforums.com/index.php?showtopic=30471

Below is Tru Oil on a black walnut / birdseye steel and a mahogany / Khaya steel.

.

-

...This weekend I'll be doing some work that really ought to be done with a drill press, so I should have a good story to tell soon.

Test your technique on some scrap or sacrificial pine first.

Wilkinson Paf's

in Electronics Chat

Posted

Sounds like you have it figured out correctly, an uninsulated wire would be ground and the insulated core is hot.