Dylanwad

-

Posts

160 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Dylanwad

-

-

I tried drilling a hole with my hand drill and a brand new bit from Axminster but found it very difficult. It took ages to get through the blank and it burned the wood, there was smoke!

What's going on with that? The bit should be fine, the drill maybe? It's a shitty thing I got from B&Q to put up some shelves years ago.

I found the smell of Walnut being cut very familiar but I couldn't put my finger on it. My friend came round last night, he smokes Golden Virginia, it's the same smell!

-

I'm looking forward to seeing this finished!

My workshop looks like there was an explosion in a Cadbury's Flake factory!

So far so good, nothing too bad went wrong!

-

The top half of the routing went ok but when I lowered the bit for the bottom half I lowered the bit a bit much and the collet hit the body. Balls! Should be covered by the roundover though.

I found the horns rather awkward to do. Any tips? The collet once again attacks. I'll have to put my thinking cap on for this one (if I can remember where I put it!

)

)

This one is in the belly cut area so no problem here.

Routing done, not bad for a first timer but not perfect. I get the feeling that a router table would make this job easier.

-

I put the Tuff Saws blade on the bandsaw today, it took a while though! I had to take the table off to get to the blade, there was a piece of the casing in the way, then I couldn't reach the bolt to take it off, I needed a socket wrench but don't have any. I was almost on my way back to B&Q when I realised the bolted piece of metal just swung to the side so you could get to the blade! :-[

As it turnred out it was much easier to set the guide blocks without the table there so it wasn't actually a waste of time. Yay! I set the blocks too close to begin with and just got a huge grinding sound, a little adjustment though and everything was fine. With that done I could start properly on the build.

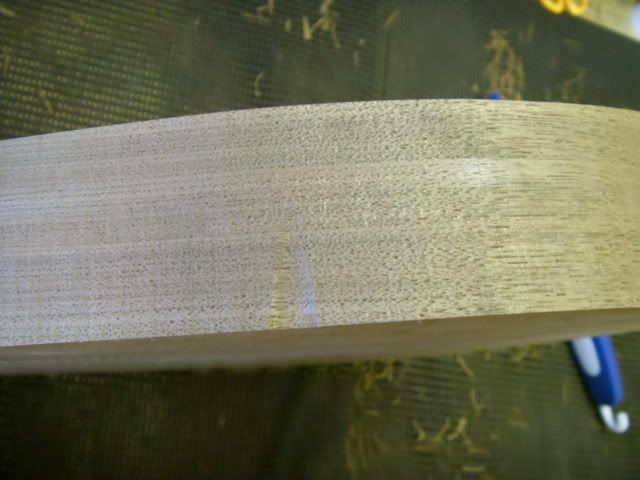

As it turnred out it was much easier to set the guide blocks without the table there so it wasn't actually a waste of time. Yay! I set the blocks too close to begin with and just got a huge grinding sound, a little adjustment though and everything was fine. With that done I could start properly on the build.The blank marked up ready for the bandsaw.

The blank marked with a chalk pencil when I realized I coulndn't see the pencil line!

The body cut out on the bandsaw. I enjoyed this bit, it felt very natural. The bandsaw performed quite well for a small one, the only time it ground to a halt was when I tried to turn a corner too quickly. Note too self - don't do that again.

The template stuck down with some vinyl flooring adhesive tape. Just a few strips around the edge as I wanted to make sure it came off! No problem.

-

$80! Bargain.

I've never found a good pawn shop guitar, just cheap rubbish being sold for way too much money. There's always that hope of finding something awesome though, I can't help it!

-

Hi Lee. I just love the colour of walnut, when I had the opportunity to buy it I just had to!

-

This has been a loooooooong time coming! Welcome to my first build thread!

Spec

Walnut body

Maple neck

Maple fretboard

24 frets

25 1/2" scale length

AANJ

Locking wheel tuners (black)

Hardtail strat bridge (black)

Volume pot - Push/push for coil tap, tele knob (black)

Three way switch

Roller string trees (black)

Straplocks (black)

No fretboard inlays

Side dots - Black or black with glow in the dark centre (not sure yet)

Neck pickup - Seymour Duncan '59

Bridge pickup - Seymour Duncan Custom Custom

Wood mount pickups

Rolled fretboard

Graphtec nut

Scallop top four frets

Jescar Fretwire 47104

Tru Oil finish all over

There's no tone knob since I don't tend to use it although I did consider putting one in so I could have one of those kill switch pots but I probably wouldn't use that much either!

Thanks to iluvteles for the templates.

-

Looking good dude! That accent line is a really nice touch, it really suits the guitar.

-

I've decided to give these blades a go due to the fact that I kept seeing Tuff Saws blades come up a lot in bandsaw discusions on forums. I'm getting 6tpi.

Straight cut

Radius cut

http://tuffsaws.co.uk/index.php?main_page=product_info&cPath=2_4_14_30&products_id=103

I'm not sure what Router bits I should get?

Roundover bit

http://www.axminster.co.uk/axcaliber-ovolo-router-cutters-prod807115/

I was thinking about the 3.2mm one, would that give me think kind of roundover?

Can you point me to what I need for the truss rod channel, template bearing bit (for the outline) and probably a shorter version for the pickup cavaties.

Also, should I just buy a set of drill bits or go for whatever I'm most likely to use? What am I most likely to use?

I'll probably buy all the bits for the router and drill of Axminster if they have everything I need.

Thanks.

-

Congrats on the new workspace !!

Thanks dude!

I ordered some templates for a 24 fret strat the other day and came across this bass today which got me thinking that this would be a cool finish for it.

I'm assuming it's a black stain on ash with white grain filler? Which would you put on first?

-

I was thinking maybe a couple of other options might be a sharpening stone:

or possible a long thick piece of mdf with sandpaper on?

-

I'm trying to decide what I'm going to buy for fret leveling. I've come accross two different tools on ebay that would do the job. This one used without the strings on the guitar.

Or this one used with the the strings on the guitar so the tension is still in the neck.

Have any of you any experience with these tools? I'm thinking that having the tension in the strings would be a good thing but it would be harder to check the leveling with a fret rocker, unless having the tension in the strings mean you won't need to use the rocker?

-

Mmmmmmm. Bananas

It took me a couple of seconds to realize what you were talking about!!

It took me a couple of seconds to realize what you were talking about!! -

It's a very small space but I'm over the moon that I've finally got somewhere to do this.

I picked up this bench for 99p!!!! I think that's something like $1.50!!!

I tried to figure out how fit in a big bandsaw so I could re saw tops etc but the space is to small so I'm going to have to go for a smaller one. I'll probably put it by the back wall by the window and the pillar drill across from the bench when I move the mixing desk etc.

As for what I'm going to build, I'm having trouble making up my mind (I can forsee a lot of that

). It's going to be one of three designs:

). It's going to be one of three designs:

or

or an LP DC design.

-

I've wanted to build guitars for quite a while now but but a lack of space and money have stopped me....until now!! I've got some invoices being paid over the next couple of weeks and I'm going to go for it. My dad has also been kind enough to let me use the back of his garage, there was a fair bit of clearing to do but it's getting there now.

From:

To:

-

Any one familiar with this saw?

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=110830491196#ht_500wt_1361

-

Would this bandsaw do the trick?

http://www.amazon.co.uk/Draper-76236-230-Volt-370-Watt-2-Wheel/dp/B00205HB1O

Or this one? It's about 30 miles away from me.

Also, when it comes to a pillar drill, how much distance does there need to be between the where the bit goes (chuck?) and the pillar. Most of the ones I've seen look very shallow.

I've looked at so many tools buy now I'm even more confused than when I started! :-\ :-[ I've got no idea at all.

I've seen talk of 1/2" and 1/4" routers too. What that about? Sorry for all the basic questions, if I can get past this maybe I can start making guitars!!!

-

This drill press?

http://www.axminster.co.uk/axminster-axminster-awbrd550-bench-radial-drill-prod719353/

Or maybe the floor standing version.

http://www.axminster.co.uk/axminster-axminster-awfsrd550-floor-standing-radial-drill-prod719351/

-

How does this look for a bandsaw?

http://www.axminster.co.uk/axminster-axminster-awhbs250n-bandsaw-prod804528/

Dust extractor.

http://www.axminster.co.uk/axminster-axminster-rdc100h-vacuum-extractor-prod794272/

Still not sure about a router or pillar drill, how much should I look to spend on a decent ones? 1/4" router or 1/2" router?

-

I'm looking to buy a router, bandsaw and drill press as I am (finally!) setting a workshop for myself. They need to be decent (do the job they are meant for) but not cost the earth. Something mid priced. I'm based in the UK so the suggestions need to be available here.

Thanks for your help.

-

Thanks killemall8.

-

Is cutting out the 'dip' on the face of a strat headstock going to be impossible to do with a jigsaw? I'm gathering from what I'm reading here that the blade flexes all over the place.

-

I can find plenty of info about which tools to buy on the forum but is there a thread about what make a good tool good and a bad one bad? I'm pretty sure I'm not the only one that's new to all these power tools and has a limited budget and is considering cheaper options without realizing the machines might not be up for the job.

I feel I need to apologize to the more experienced builders with better equipement. I feel a bit reluctant in spending a lot of cash wthout knowing if I've actually got the building skills! Better equipement would help me to build but they're expensive, it's a catch 22 situation!

-

Walnut / Maple Superstrat

in In Progress and Finished Work

Posted

I finally got back into the workshop! I tried my planer out for the first time and it worked a treat considering how cheap it was! Once I got everything flat I marked out the truss rod channel.

I set up the router.

And then I cut one ugly ass route! I didn't leave enough space at the heel end to clamp it properly, I also need longer clamps. The first pass wasn't bad (about 1mm) then I routed to the final depth when I should have kept going with several passes instead. This woodworking lark sure lets you know if your doing it wrong! Will it be ok like this? The rod is pretty snug in most of the route.

I noticed after routing that I had placed the nut in the wrong place but I put it in the right place and I can still reach the rod with an Allen key.

I cut to the line on the bandsaw and then the template was then stuck on with some vinyl flooring tape. I then tried to use my router table for the first time and quickly realized that the router supplied with it doesn't stay on unless you are manually holding down the switch, why supply a router for a table that won't stay on unless your holding it? Some electrical tape solved the problem. I then realized that the wings weren't flat with the table and spent the rest of the day taking the bloody thing apart and by now I'm half way to putting it back together! I'm having a bit of trouble setting the router to the correct height on the table due to the insanely stiff springs. Is there anything I can do about that?

I have to admit that my least favourite tool so far is the router, it's brutal!