-

Posts

345 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by toddler68

-

-

Gonna be purple, like the last one. It's for the same guy...

-

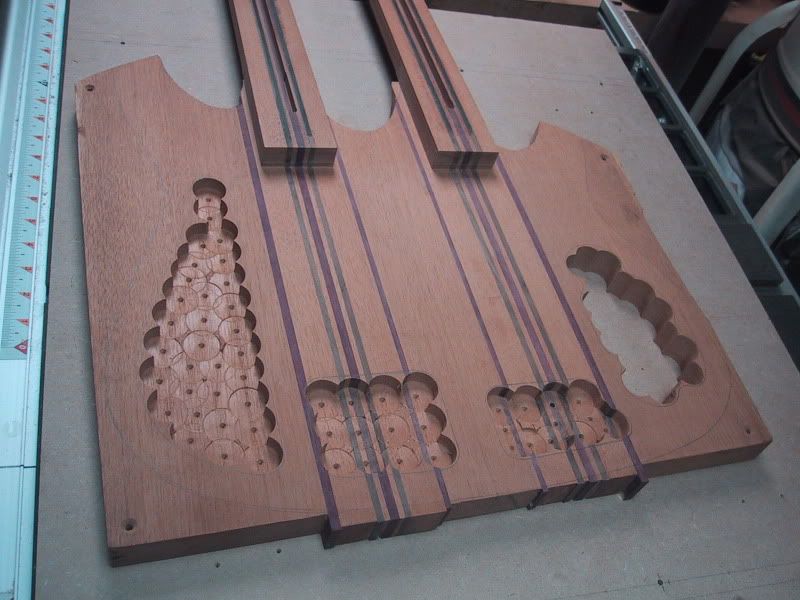

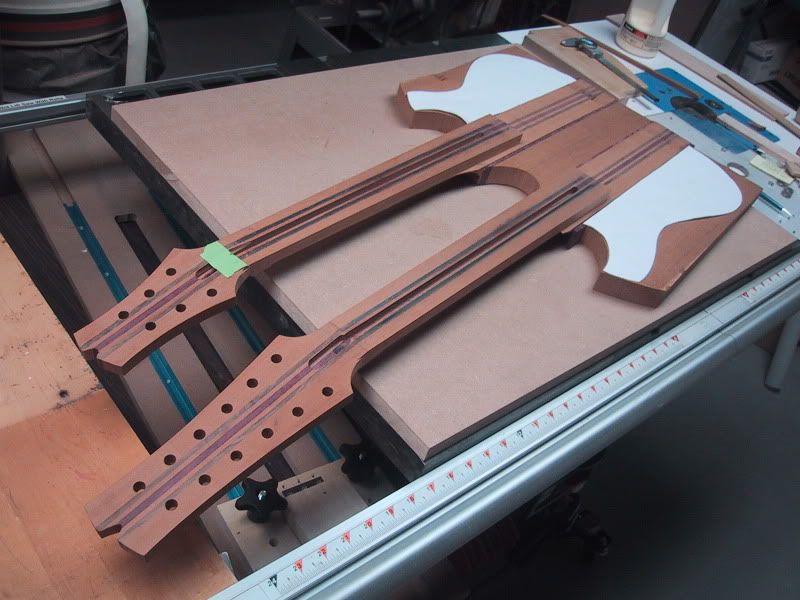

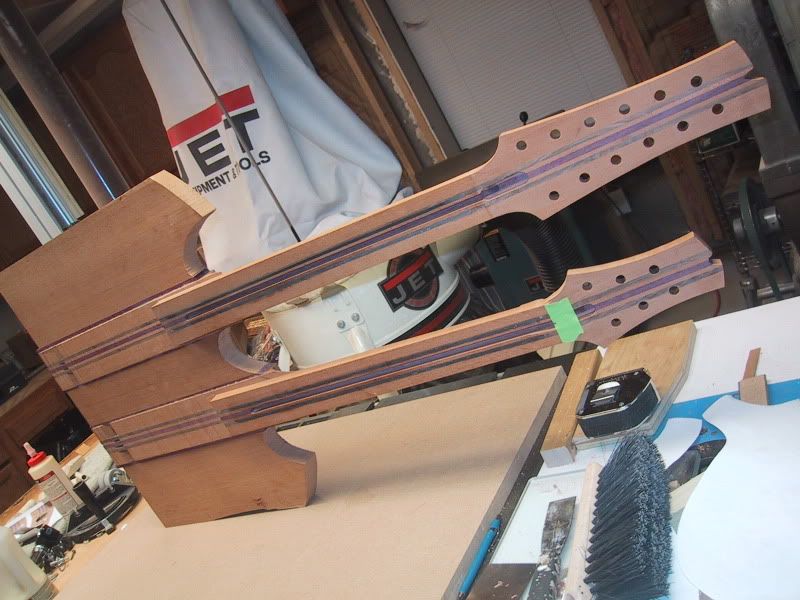

Here's a pic of the fretboards routed to width and test fitted and beginning to cut the body profile

-

Template screwed to the back of the top to hollow out the backside.

Template removed

View of hollowed out sections

-

Then I shaped the top to dovetail into the two necks:

Template screwed on and pockets cut

Template removed and fitted to body

Pretty tight fit

-

Here's the top being glued up... I ran a couple 2x4's from the ceiling I-beam to hold the center down. Worked pretty well.

-

its looking really good.

I just have a question about the neck layout as i am struggling to decide what to do with my bass/12 string double neck

I see you went with parallel necks with quite a distance between them - how did you decide on this?

I think i am going for a slight angle on mine with them being closer together than yours but i dont want to go too far and end up with the BC rich layout of having each neck nearly meeting at the bottom end

Well, I really just kind of eyeballed the spacing between the necks based on perceived hand clearance requirements. And actually, you can't really see it but there is a very slight angle between the necks... the "wedge" body piece between the necks is 1/16" wider toward the headstock, so the necks are diverging as you move toward the nut. It wasn't really planned; just a happy accident with my planer

-

Better?

Before:

After:

I'm actually surprised at how much lighter it feels just taking that little extra off.

-

Thanks for the feedback, Mark. Actually, I had given your double bookmatch idea some thought early on because I thought I'd have trouble finding a piece wide enough. But I did run across an extra wide piece on eBay which the client likes. I showed him examples of the figure in every possible configuration and this is the one he chose. It works out quite well because most of the flame will be toward the perimeter and not hidden by the pickups/strings/bridge. I just hope I'm able to accentuate the flame that is present.

-

looking good, But id chamber out more of it. Double necks can get realy heavy. I have one on the go just now & have almost hollowed out the whole top guitar because of previous experiance.

Any idea of the weight of this one at the moment ?

I was hoping someone would "weigh" in on this subject. I don't want it to be too heavy, but I still want there to be enough structure for sustain. Right now I think I've got it at close to 1" around the perimeter and about 3/8" thickness at the bottom of the cavities. Is there a rule of thumb as far as how much material thickness to leave? 1/2 inch, 1/4 inch?

I'm also planning to rout matching shallow cavities into the topwood before I glue that on. Any other suggestions are greatly appreciated.

-

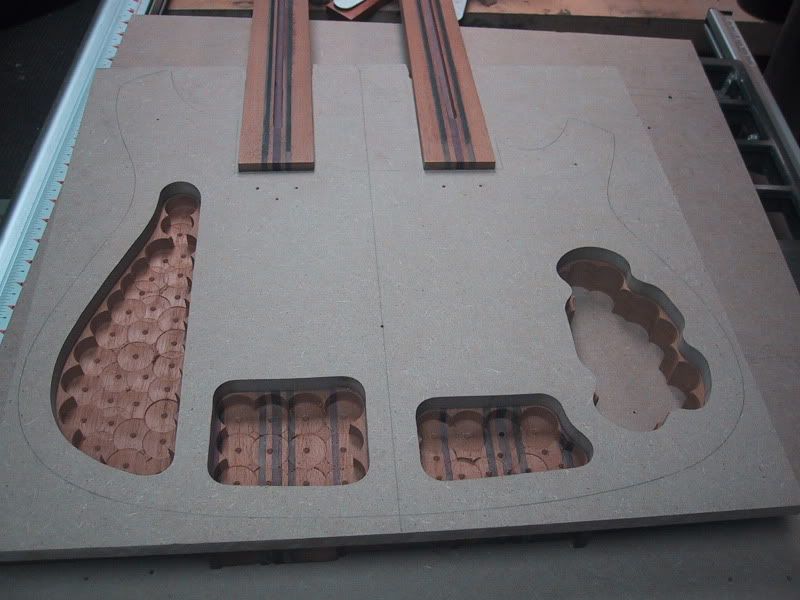

Cavities all cleaned up:

-

Slow progress, but progress nonetheless.

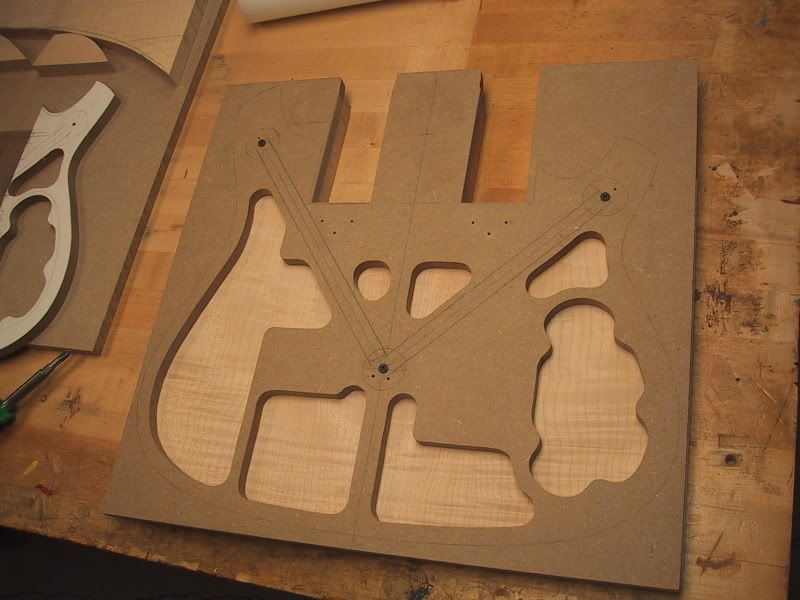

Templates for chamber and electronics cavity cutouts:

Holes hogged out with Forstner bit:

Template removed:

-

adjust the high e saddle 7/8 of the way forwards - towards the nut

the high e saddle break point (easier to measure on the side saddle rather than the round one) should then be 25.5" from the nut - and you will have plenty of adjustment backwards for setting intonation on all strings, you also have a slight amount of forwards movement incase you are a small amount off in your measurement

That's what thought. I think the bridge came already set up like that. Thanks for the confirmation!

-

Can anyone give me some guidance on how to mount this bridge (which saddle to line up with my 25.5" scale length)? Treble side? bass side? Middle of the bridge?

Any help would be much appreciated.

-

Here's a comp of the top wood:

Since this is for the same client as the last one, it will receive a purple dye job. Man, I'm glad I saved the recipe...

-

I think I finally have a logo that I can live with...

-

Been out of the loop for a good while, so I thought I'd post some pics of my latest project. It has taken me over a year just to get to this point, but I'm still hoping to beat my record of 2 years!

Will probably be chambering this puppy to save on weight. Maybe I'll focus on the 12-string so it will have a lower center of gravity and be a little more acoustically inclined.

-

1

1

-

-

-

yeah, I was wondering the same thing. I'll have to take a trip over to his house and have a look-see. Maybe I'll take pics.Curious as to how has the color of the purpleheart has held up...? -

Speaking of this build being bumped...Toddler! Where's new stuff!?

Chris

Funny you should ask... I've just started working on a double neck version of this same guitar for the same guy. When I've got something to show, I'll definitely start a new thread.

This one's gonna have the same purpleheart and walnut laminates in the neck, but the maple will be replaced by mahogany. It'll probably also have a tiger maple top instead of burl, but it will still be dyed purple. Not sure about the rest of the hardware etc... still kind of up in the air right now.

-

Outstanding work!! Very inspiring!!

Did you have to do anything special to prevent the dye from soaking into the binding?

Standard "faux" binding technique which I learned right here on this forum. Mask everything except the edge and shoot a couple coats of lacquer just on the binding edges. Let it dry and pull off the tape. When you go to lay down the dye, it won't soak into the lacquered edges. Voila! Instant binding...

-

Must be butternut. All the basswood I've ever cut had a flowery smell to it. Quite pleasant, actually.

I was working with a bunch of woods for the desk clocks, so I can't remember which one, either butternut or basswood... DANG! Straight-up dirty underwear. It's just gawd-offal. -

That neck is so gorgeous I can't stand it!

:D

:D  A triple drooler!

A triple drooler! Have you clearcoated it as well, or is it just polished?

-

That's niiiiice. Is your fretboard ebony? The contrast between the tiger maple binding and the fretboard is stellar. And what are the laminates on the back of your headstock? Also a very nice detail. Hmmm, I think my next project should be an LP...

-

Oh sorry, I thought that was obvious, yeah you pull it around to the back side of the frame and glue/staple it back there.

Thanks guys. I confirmed as much after checking out an old Twin down at Guitar Center. Looks like I'll have to get a bigger piece then. Anybody need an 18"x36" piece of Fender grill cloth?

Third Build - Double (neck) Trouble

in In Progress and Finished Work

Posted

Really sharp chisel... works like a champ. Except, I'm not sure how to re-sharpen it when it gets dull. Maybe I'll just have it professionally sharpened or buy a new one every time