peterbrown

-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by peterbrown

-

-

Very nice decadentjon.

I realy like what you do with the traditional tele. You definately do things with the tele shape that I have never seen before. Tasteful. Look forward to seeing more of your projects.

Cheers,

Peter

-

More pics of the body shaped.

Cheers,

Peter

-

Nice,

I didn't realise you could do all that with free software. I guess the limit is your imagination. One tip I would add. Always plot with a scale bar or a line of a known length. Measure it before you cut to check that the print hasn't been scaled anywhere along the process. You can make an error in the scale from the design itself to the viewport scale to the export to pdf, tiff or whatever, and then resized accidentally when you press print, especially if you get someone else to print it. Some people just click "scale to fit page" which even if it's only something like 98%.. thats still a 2% error.

I've been using CAD for a while now, and whilst it does cost a bit. I would list it very highly on my "most valued tools list" Worth the money I think. But I do like the paint story. if in doubt try paint.

Cheers,

Peter

-

Thanks WezV

I know what you mean about the splinters. Here are some pics of shaping the back and the recess for the cavity cover,

Cheers,

Peter

-

Hi,

I call this one the "Star Single Cutaway"

Neck - Laminated New Guinea Rosewood the maple stringers

Fretboard - Santos Rosewood with custom "Star" MOP inlay.

Headstock veneer - fiddle-back blackwood with hand engraved MOP "dragonfly" inlay

Body - Chambered Blackwood

Top - Carved Bookmatched Fiddle-back blackwood.

Pickups - Seymour Duncan 59 in the neck and custom custom in the bridge. Both coil tapped

Hardware- Gotoh

Cheers,

Peter

http://i243.photobucket.com/albums/ff38/si.../neckfinish.jpg

http://i243.photobucket.com/albums/ff38/si...ey/P8170301.jpg

-

Thanks for the comments.

Wenge is one of my favourite timbers at the moment. It is a beautiful timber to leave unfinished due to it's oily nature and opened grained pores, it feels realy nice to play and has realy low friction, which makes it feel faster. The only disadvantage is that it is heavier than most traditional neck woods, however the extra sustain and resonance makes up for it twice fold I think.

Here are some pics of carving the top. Still a few blemishes to sand out.

Cheers,

Peter

-

Hi,

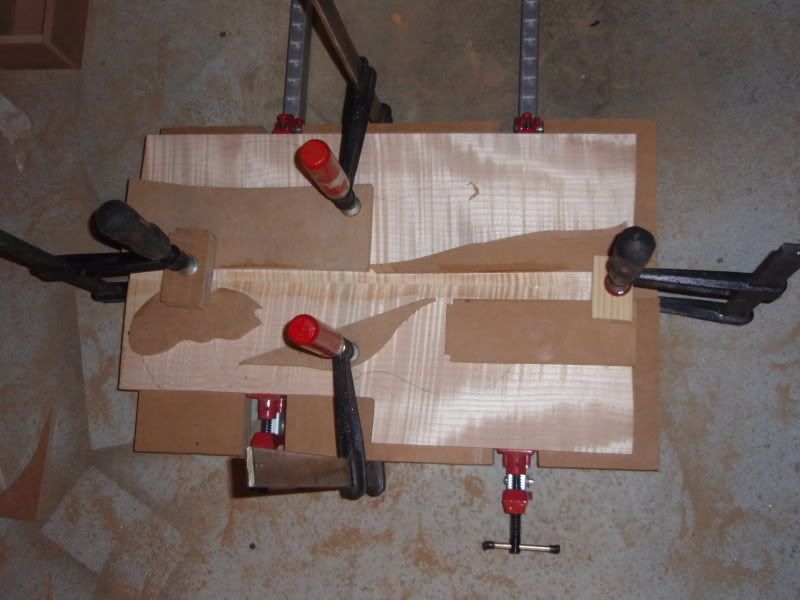

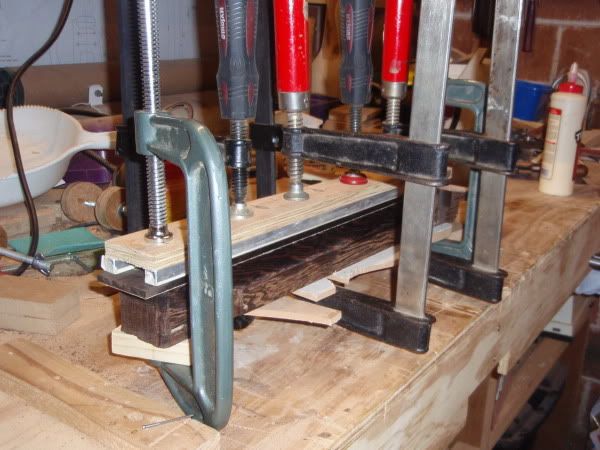

Got some more progress pics of working on the body. The first is glueing up the top.

The top glued on and the body routed with the rear cavity.

Cheers,

Peter

-

Looking good.

Is it going to be a burst?

Cheers,

Peter

-

Nice Laps fellas. Not something you see too often on the forums, and much appreciated. Very nice.

Cheers,

Peter

-

That neck is sweet!

Thanks Neil,

The neck feels realy nice as well. Heres some picks of the neck shaped and rough sanded.

Cheers,

Peter

-

Thanks Decadantjon and Xanthus. The carve will be grdualated for the body and sharper around the horn. The line on the plans is more like a control line as a guide. i won't be chambering this particular build, however I have made up the template for future builds.

Some more progress pics below.

Gluing on the fretboard

The neck blank with the fretboard on.

The fretboard radiused and a lick of linseed oil ready for fretting.

The neck roughly shaped. Still need a bit of shaping.

Cheers,

Peter

-

that body shape is going to look mad with the zebrawood. The vertical stripes will look great in those violin cuts. I agree with Xanthus on the upper violin cut, and maybe the lower horn could be a little wider? But I realy like the design. Looks like it could take an eye out

. Hope you get some more time to work on it soon

. Hope you get some more time to work on it soonCheers,

Peter

-

your not kidding about getting a few commissions. Nice work. The bear is my personal favourite. Was a tough choice though. i like your choice of timbers on all the builds. look forward to more builds,

peter

-

Thanks Swedishluthier. Your comments are welcomed and suggestions noted. Feel free to post comments anytime. I have to admit I toyed with the headstock design for a while, and just opted for the simple option, as I like to keep things a little understated.

More pics of the inlay.

Cheers,

Peter

-

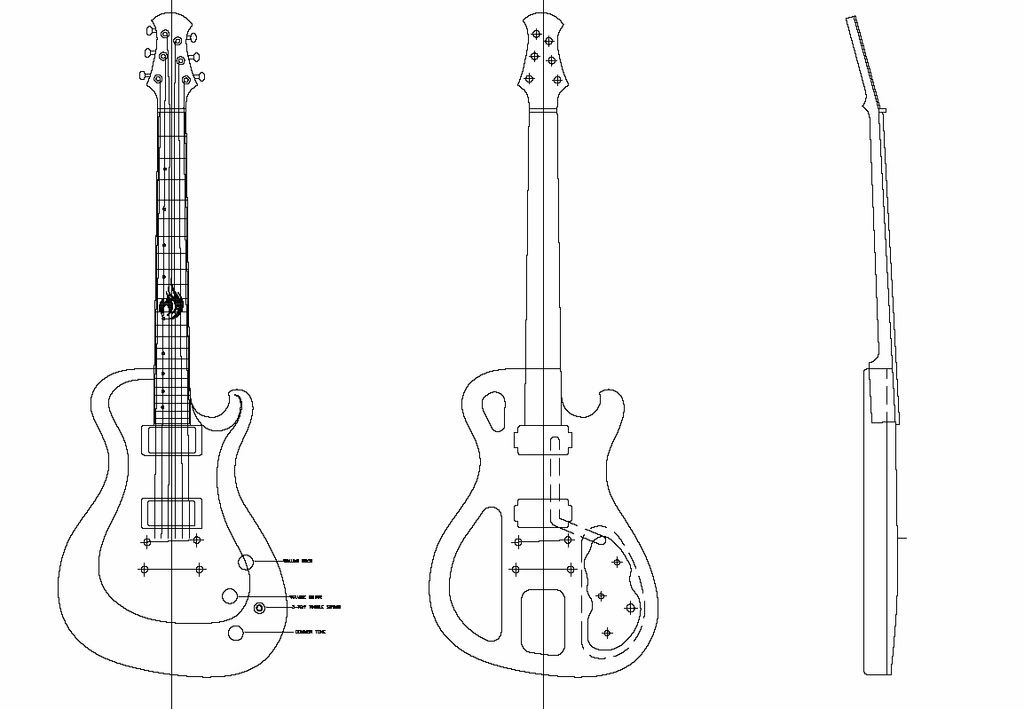

Hi,

I have a project to share with you all. It is a new design I have been working on for a while, and what better way to test it than to build it.

Firstly the CAD.

The specs for this build are:

Fretboard: Ebony. with gold MOP inlays

Neck: 1 piece quartersawn wenge

Body: Fijian Mahogany (Honduras)

Top: figured maple

Cheers,

Peter

-

Nice work there Ethereal.

Nice choice of timbers. Definately got me thinking with your chambering design. Is there anything significant with how it has been chambered? If it's a trade secret, best keep it to yourself, but it did get me thinking. I like the shape also. Can't wait to see a lick of finish on that top... pop!.

Cheers,

Peter

-

Very Very Nice. How did it sound for her compared to her original ?

Lets just she was a very happy customer,

Cheers,

Peter

-

Fantastic! In my opinion this is the best "project guitar" guitar in a long time. I like your take on the traditional single-cut's set-neck the most, was there a reason for this method? It looks great.

Thanks,

I assume you mean how the bottom of the heel meets flush with the back of the guitar? The main reason for this was due to the body being thinner than average (36mm at the edge, 47mm at the centre) and I wanted the neck heel to remain the standard depth (if there is a "standard"), so I made it the full depth of the body, which also looks good too, I think.

Cheers,

Peter

-

Hey guys,

thanks for the feedback. If I was to do it again, I probably would consider a different pickup colour other than black. I was thinking silver rings, or no rings at all? Or even timber rings maybe? I just picked up a large billet of the blackwood for more tops and I think I'll trial a few options for the next blackwood guitar I make. The finish is waterbased colortone from Stewmac with a thin coat of blond shelac underneath. I love the WB colortone, is much better on the old lungs and environment than the trad solvent based.

Thanks again,

Peter

-

Hey Bryan,

Thanks for the positive words. I was originally thinking about engraving the star, but when I radiused the fretboard, I realy liked the look of the star as it was. But you're right, with engraving, the limit is your artistic ability...

The jack is a flush mound jack from stew mac.

Cheers,

Peter

-

Hey,

Have finished this one a few weeks back and thought that I'd post some pics of the finished product. Am very happy with how it turned out.

Cheers,

Peter

http://i243.photobucket.com/albums/ff38/si...ey/P8090281.jpg

http://i243.photobucket.com/albums/ff38/si...ey/P8170301.jpg

http://i243.photobucket.com/albums/ff38/si...ey/P8170289.jpg

-

Geo, your right on about the star of Bethlehem, it was what I kind of based the design off,

Have finished sanding the guitar and have ingraved the dragonfly inlay. Picture is below:

Cheers,

Peter

-

Thanks for the feedback fellas,

Sorry Xanthus, didn't quite get what you meant by the Dave Myka comment.

The neck to body join was purely intentional. I'm building this for my sister who is small and finds her current Les Paul copy heavy and awkward to play and asked for a shorter, lighter instrument. She rarely sits high on the fretboard, so positioning the joint slightly higher, gets a slightly shorter overall instrument and maintain a standard scale length. The 22nd fret is still quite accessible. The body is about 90% of a standard Less paul size, and Geo you are correct in it being thinner than normal. 35mm at the edge and 47mm at the centre, which makes for a very playable instrument. Quite light too with the chambering and the slightly shorter neek maintains excellent balance.

The wood wheels are centrally placed and just screwed in for each individual guitar, however the offset cam is a very good idea.. mmm... might steal that idea.

Cheers,

Peter

Thanks Again

-

What have you got to do to earn your right to "sell" a guitar? It's just a hunk of wood anyway. I've seen guitars for sale in a music shop for $80 that I recon would make better fire wood than instruments. No one questioned their integrity! Some opinions should be taken with a grain of salt.

By the way. I would love to see this body through to the finished product, but ya gotta do what ya gotta do,

Cheers

Peter

Carved Top Strat

in In Progress and Finished Work

Posted

That is a sweet look with the danish oil. Nothing like an oil finish to make it pop! And the black binding contrasts the orange nicely and defines the outline of the guitar well. A good look I think.

Cheers,

Peter