Jdogg

-

Posts

105 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Jdogg

-

-

Small update....

peeled the old fabric off this weekend....

Came off as kinda like one giant sticker....

sanding the LMII glue back to the body was nearly impossible....

danm LMII glue is hard as nails once it's set....

Also noticed I had a few more little tidbits hidden under the fabric that I couldnt see.....

Turns out they were all stray fibers from the fabric... so I made sure not to make that mistake twice....

Soo..... got everything level and tried again.... this time im using LMII glue to fill the fabric... and it seems to be working... just need to wait for it to dry completely so i can see if it'll sand smooth...

-

I also use Rhino, but i've never used any of it's 3D functionality.

For those on a budget, there are several free cad programs out there...

Also, If you know a full time student at a university most of the auto cad type companies give rediculously cheep liscences to students... Im assuming the rational is if you learn on drafting program "A", given the oppertunity, you'll be more likly to choose program "A" once your out of school.

-

I've been following that tutorial pretty closely for the last little bit...

He reccomends the mod podge... which is why I tried it in the first place...

this time i'll get a real pore filler and do it right...

lesson learned.... hopefully....

-

So,

Long story short.

I had the last week off of work while I was moving.

got alot done.

Sanded the black paint off so it wouldnt show thru the white fabric. (the photo is about 1/2 way thru the process... VERY thick finish on this one..)

Tested the lmii glue on a sample...

worked well...

tested the mod podge... worked well.... so i thought....

So I went ahead and glued down my fabric on the guitar

All was going well...

I applied 3 coats of the mod podge...

all looked well....

untill i started sanding....

it was terrible...

the mod podge didnt dry even after several days....

it remained tacky indeffinatly....

so it would litterally ball up, load up the paper and then stop sanding essentially immediatly...... It was like trying to sand hot rubber....

and it just got worse from there....

I had a little more luck wet sanding... but that's a whole new issue....

then i found out that the lmii glue hardended soooo fast I didnt get a chance to get all the bubbles out... so i had a couple sand thru pockets.....

but i kept at it....

and finally got everything level... with a couple of tiny holes where i'd sanded thru....

so i brought everything into the house and put everything together in a nice neat stack so my lady friend wouldnt have a kaniption fit.....

when i returned several hours later I found that the mod podge had glued itself to the sandpaper i put on top of the guitar body....

then i noticed the blade of grass that i'd somehow managed to glue down under the fabric....

I can kinda see it in the picture... between the two pickups kinda by supermans feet in the white area..... FML!!!!

so yeah... round 1...

fabric finish 5

jdogg 0

It's on... it's on like donkey kong my friend....

I think I'll light the rest of my mod podge on fire.... and check at windsor plywood for a REAL sanding sealer....

sooo much anger....

-

I WILL BLEED FOR METAL!!!!!!!

Epic win... Im assuming that's blood and not just stray ketchup from his lunch or something...

Either way, the visual strikes me as being quite metal.... so I had to comment...

-

Sounds OK. Be sure to test the titebond on the white first. Us titebond original. Iv never used wood glue where there is white in the fabric. Usually a 2 part clear epoxy. Make sure you use plenty of grain filler aswell. leaving a day at least between applications. Then wait at least a week to 10 days before you clear it to let any moisture introduced into the guitar escape.

You should use a few bulking coats of clear before you try level it for the final coats. sanding thru to the fabric is an absolute bitch

Good luck with this. Keep us posted. & remember - lots of piks !!!!!

I've got some LMII luthiers glue that's supposed to dry clear... do you think that would be a better choice? I just chose titebond because that's what's in the DIY.... Perhaps i'll try both on scrap and see how it works out....

-

I appoligize but im clueless when it comes to fabric... it's a medium weight cloth i would guess.... not overly heavy not overly light....

Game plan is to sand the top down to the bare wood (looks like alder) then to use titebond to glue the fabric down to the bare wood.... fill with a clear filler and get my buddy to burst the edges with his airbrush... then some clear and done.

-

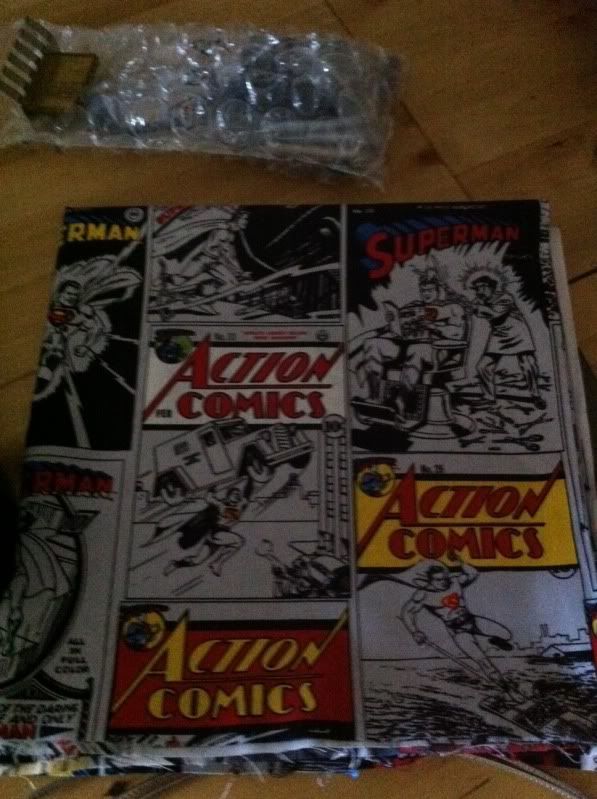

Heya Guy's,

Im doing a fabric refinish on a jackson JS30 that im fixing up.

Reality is Im using it as a guinny pig for working out my fabric finish tecnique for my next custom build... so I'll likely sell it (hopefully to get back my $$$ from the mod's / refinish) once it's complete.

I've chosen some fabric... but im not sure about it... so im loking for some opinions....

It seems like the kinda thing where you'd either love it or hate it...

Body and fabric

and then the neck to go with it...

replaced the cheep dots with some black MOP dots i had laying around that just happened to be the correct size... black mop = epic win if you ask me... looks good...

Whadda ya all think.... Epic win or epic fail????

-

I like the idea of doing it as a '54, but you will probably need to use a flux capacitor on the tone control.

Werent those outlawed when some hoolingan went back in time and framed Tonya Harding???

-

I've used aluminum foil with a non conductive spray adhesive before and had absolutely ZERO problems with getting everything conducting together...

but then again... it's better to be safe than sorry... so the dimples make sense to me...

overkill... maybe... maybe not....

-

What's the story with the dimples?

Is this to ensure continuity between the layers of metal or to help ensure it stays put???

-

If the customer follows a few simple logical rules, the instrument will last forever...

Are you willing to share your views on correct instrument care?

I've never really heard a solid set of do's and dont's other than dont leave it in your trunk on a hot sunny day and dont take it out of the case untill it's adjusted to the new climate....

-

Thanks for all the help!

I really appreciate your input!

-

Do you find that leveling under string tension makes a differance vs leveling with the strings off????

-

Actually,

I'd like to know how you drill that ibanez jem style input jack....

I botched my first attempt and would like to know how others do it....

-

I've been looking for ways to improve my fret leveling quality..... and I ran into this...

http://rectifymaster.com/index.php?option=com_content&view=article&id=7&Itemid=29

Im not affiliated with the above...

Im just looking for oppinions....

I emailed them and it looks like it's about $130 shipped to canada plus brokerage... prolly another 30 bux or so....

seems like an overpriced item to me.... so i've started looking for similar items from local suppliers but i cant find anything even remotely similar that i can make work.....

Thoughts????

-

I've seen it done before.

Found a website with a gentlemen who builds multiscales...(of course i can never find this stuff twice....) he prefer's LARGE fretwire and a flat fretboard... soo large in fact that he couldnt find any to suit his needs... so he claimed to use stainless rod of some sort.... not sure exactly how he did it tho....

I've also read that parker glues their frets to the fretboard without a tang... im assuming they use wire with a half round profile tho....

either way.. it deffinatly could be done....

-

I like it!

Question,

How do you find setting intonation on that bridge? I was considering using one but steered clear as it looked like intonation would be a pain in the butt...

-

Alright,

So, I've been planning #2 for a couple months now....

This will be a 3 part build

Part I

Multi scale nut....

I plan to make the main part from Brass

and the string locking bit's from black buffalow horn

Part II

Multiscale bridge....

I just need to remake the plate that the saddles bolt too... but the angles are gonna get pretty retarded....

I'll likely end up using steel....

Part III

Build the rest of the guitar....

25.5 / 24.75 scale lengths. 10th fret will be the strait one.

Body shape is to be similar to an ibanez jem except I plan to change the lower horn a little...

body wood is likely to be mahogany or sapelle...

Neck will be 24 fret... jumbo stainless steel frets... 16" radius.

Padouk for the neck wood and Wenge fretboard.... offset pear dot inlays....

I've been neglecting to post anything untill I actually have something worth posting... so here it is....

Sorry for the terrible photo's....

Here is my nut about 2/3 finished.... i still need to angle cut the sides.... i may just do that with a file.... and then drill and tap the holes for the locking blocks...

I would also have some photo's for you of my locking blocks... but we had a little incident on the mill... apparently using a crappy old bit to surface black buffalo horn is a bad idea... i got nasty tearout and it wrecked the pice... so it's back to square 1 on that.... no biggie... i've got lotsa horn left in my stash...

-

I really like the body shape on this one...

very nice...

-

I vote for the red as #1... orange as #2... both colors are spectacular.

lookin good.. i like the shape...

-

+1 for the acoustic shreading... that shyt's da bomb.... this acoustic may need a whammy bar.... functionality of said whammy bar is totally optional.... shreding simply is not...

-

I can only correct my mistakes and learn from them.

You can also whine, cuss, cry, and of course... throw things...

but i suppose those are optional...

Then again... so is learning from your mistakes....

-

Still working on some pro pics... proly have the G/F do em.....

perhaps i'll wait till the pickup rings are done.

In the mean time I swapped some thicker strings onto the guitar.... Actually only swapped over the 3 wound strings. I like the unwould strings from the lighter set... was running .009 to .046 tuned down to drop C. she got a little flakey on the last 2 bass srings so I was hoping to tighten things up a little. swaped in .010 to .052.

Got a little more girth than i was barganing for.... danm thing feels like the strings are HUGE..... but it's tighter than... well... we'll leave the "how tight is it" reference out for now.... but yeah... it's tight....

I may have to resort to a custom set something like a .009 to .048 or .050

maybe i just need to get used to the new set.

Groges Signature Spec Superstrat

in In Progress and Finished Work

Posted

I'd have to agree with ripthorn.... black camo is epic awesome...

We, The people of project guitar, Demand a DIY.....