iluvteles

-

Posts

236 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by iluvteles

-

-

Thanks Wez. One more thing. If I do danish oil the Wenge fretboard does that mean I cannot then treat it with lemon oil once a year to clean and nourish the wood. I.e. will the Danish oil not let the lemon oil into the wood? One its Danished oiled is that the end of it like a laqured maple fretboard?

If you understand what I'm getting at.

-

If this was your guitar Wez what would you do to the Wenge fretboard?

-

I'm planning on using Danish oil on the Goncarlo neck back. What do you all think about using danish oil on the Wenge fretboard also. OR should I use lemon oil on the wenge fretboard and danish on the Goncarlo back?

-

Thanks for the reply's. Thats what I'll do. I'll drill a 12mm hole and plug it with a bit of Goncarlo. I'll do all 6 even though its the A and D that are the worst. I;ll do them all and hopefully gut them nice and snug. If I dont I will only regret it later.

I just get a bit fed up with the stupid mistakes that I make.

-

Thanks for the reply Ripthorn. You are right I should plug and re-drill. I'm just a bit down about making so many mistakes on this build.

-

Well I've did it again and messed things up. This drilling is really bad and the machine heads wobble all over the place. I cant be bothered to drill and plug then re-drill because I'm loosing interest in this build so I'm looking for a way to bodge it up. I was thinking of fitting the machine head then pouring epoxy down to fill the gaps at the side. Any suggestions on what to do apart from get a grip of yourself and do the work to put it right i.e. plug and re-drill.

-

Not much activity just rounded over the edges.

-

I think I may have made thing seem worse than they are. The high fret is now sorted and the bash marks are a there but not the end of the world. I have wiped them with water to expand them a bit. It does help but does not cure it. I'll have to sand them out the rest of the way. I think I'll get away with it and its one of those things where I know its there and its agrevating but not the end of the world. I'm just going with it. as for scalloping, Ilove scalloped necks andI have a YJM strat but this year I have wrecked 3 necks trying to scallop them so I have given up on it.

I know I'll call it custom relicking

-

Thanks for the advice Ripthorn. I have a set of the stew mac brass insert and I did use them to press the frets in. The trouble was that the 12" radius on the fretboard was more like 9" at the sides, first time I have radiused. So the frets were sticking up at the sides so I bashed them down with a hammer thinking I could just hit them and all would be well. I have now lernt the hard way. I should have used a bit of wood on the fret and then hammer the wood.

A beginners mistake I will not repeat

-

I did consider taking the fretboard off but I dont have any Wenge left so decided to try and repair first and then see what happens.

I pulled the high fret and replaced it. There was some chip out but nothing too bad as they were then covered with the new fret.

As for the hammer marks I'm going to try and sand them out and then see what its like.

-

OK I radiused the fretboard and I,m not 100% happy with it. It seems to be different radiuses along the length. Anyway I put the frets in and they did not seat properly at the edges where the radius was smaller and to round it off the 24th fret is standing proud at the edges and no amout of bashing down will make it stay down. I will have to pull it out but I just know that the wenge will come away also. AND I,ve bashed the frtboard with a fret hammer and it looks shite

I think that this is scrap neck number 4 this year :'(

-

Thanks for the reply and advice. I ran the board through the thicknesser down to 6mm and it looks better now.

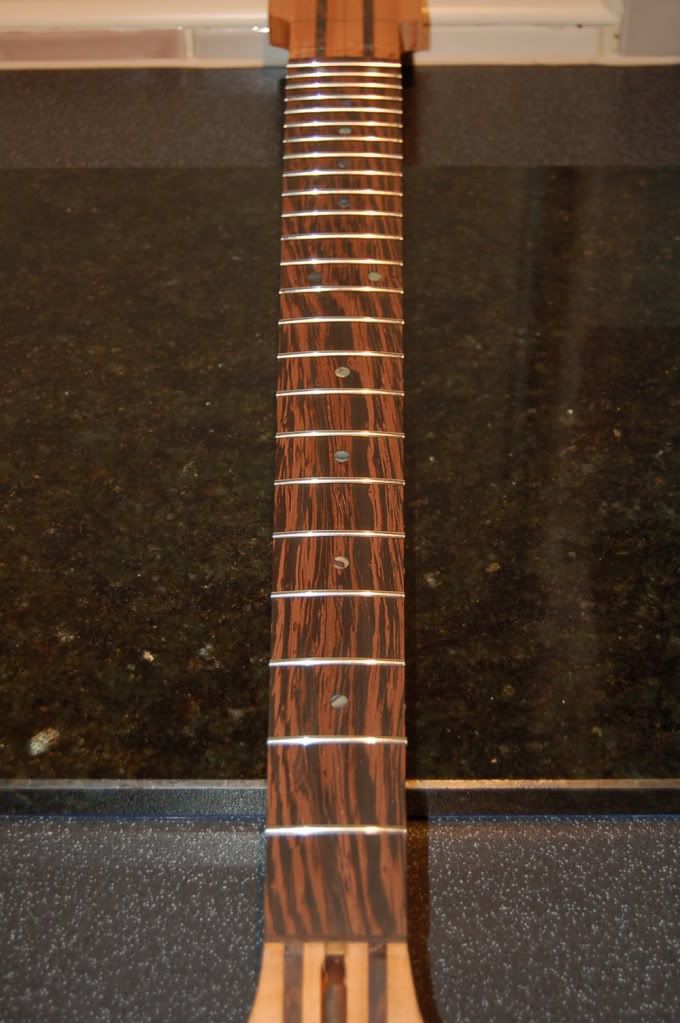

Yes the Wenge does look nice but its very chippy and even double sided tape pulls lamination away. I think once it is sanded and lemmon oiled then it will look nice. This neck was going to get a jatoba fretboard util the Wenge came along.

-

I now have the fretboard glued on and profiled. I'll radius the fretboard next.

-

I have slotted the Wenge fretboard but I'm a bit concerned that I've made the board too thick. Its 8.7mm flat. The radius will probably eat away 2mm making the edges 6.7mm and 8.7mm in the centre.

I'm thinking of running the back through the planner and removing 1.7mm off the total thickness.

Any thoughts anybody?

-

The neck is all profiled out now. The headstock was done freehand and I'm not 100% on the quality of the work but since its the 2nd spare neck it will have to do. I just did not want to sand anymore incase I went too far so this is it and if it bugs me a year from now then its all down to me and my pap freehand profiling.

While profiling out I have unearther a small hole. What should I do with it. Superglue and sawdust?

-

After the advice by ResterationAD I used Tighbond original on the scarf joint. I used Poyurathane on these little bits just to use the poly up. Once it is gone I will only use Tightbond Original. The only glue ups I have left on this build is the fretboard and the neck joint. I will use Tightbond for both.

-

The headstock was just a little bit short so I added two bits of wenge to either side to build it up.

-

I routed the truss rod channel today and was going to rough cut the neck out but noticed that I was 5mm too short on each side of the headstock so I'm going to glue two little bits of Wenge to build it up and then cut it out.

Though I would include a pic of the Wenge fingerboard just to show a bit of the design. The only problem is that I've cut the board to thin at 6.3mm and I think it should be more like 8mm. I'll have to cut another.

-

neck number 2 has now had the top part milled flat and also the headstock has been milled flush and down to 15mm thickness. Just need to mill the truss rod channel in next.

-

OK a bit of amn update. I decided not to use the original neck blanks because the headstock was too short. I had a spare neck blank so started to remake the neck and I made exactly the same mistake again. I wanted a 200mm headstock so I measured 200mm drew a line and cut it. When I flipped it over to do the scarf joint its was the same length as the original. I have learnt the hard way. Because its cut at an angle you must add the length of the angled cut onto it so when its flipped its the right length.

So...I cut a new bit off the original neck blank and cut a new headstock to the correct length.

I've used some cut off nails to stop any glue slid this time and also some tape. All glued upm now and drying. Fingers crossed.

I am a eeeejut.

-

Hi Wez, its about 50mm short after taking 5mm off the thickness. But the main problem is that its starting to bend. Its its not flat at this point in manufacture then I think its scrap.

-

I've been following this over on UKGB and I copied your take on the router jig to flatten the body blanks which now I find out you copied off someone on PG. Thanks whoever you are. Its good that other DIY guitar builders are using the clever jigs to help us all.

Your build is coming on and as already said the router defects happen all the time. As least to me. I just blend them in with sandpaper. After all if you want a fender. go and buy one...no harm done

-

The Goncarlo Alves and Wenge laminated neck looks great but its warped and to add fule to the fire I've made the headstock to small. I should heed the measure twice and cut once rule. This is now in Lee's junk pile.

I'm thinking about trying a non laminated neck made from Utile with a Wenge fretboard.

-

I've profiled the body out now to its final shape. Had some tare out and one are where the dug in too much. Nothing that cant be sorted.

Lee's Spalted Beech Tele

in In Progress and Finished Work

Posted

Thanks for the support Wez. I think I'll just danish oil the whole thing. My original intension was to make a neck that does not require any finish at all but it just does not seem right to leave it tottaly bare so I think Danish oil is a good inbertween.

Cheers Wez