bugman96

-

Posts

97 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by bugman96

-

-

they come unfinished, unless you pay them to lacquer it up.

-

So would I have any problems if I took a graduated height 6-inline set and converted 3 of them to use on a 3x3 headstock since you get 2 of each post height?

-

I like it. Reminds me of the one I've been planning.

-

So I know the 6-inline sperzels come with graduated post heights to eliminate the need for string trees on necks without an angled headstock. If used on a neck with an angled headstock would it make sense to put the tuner with the shortest post closest to the nut to eliminate unecessary tension on the strings?

-

thanks

-

They look nice. What did you use for the body edge of the walnut/mahogany guitar

-

I've been searching around for prices for electronics that are cheaper than stewmac and found Grizzly. Has anyone here bought their pots or switches and could comment on their quality?

-

Did a search, found nothing. Planning on mounting HB's with rings on a tele-style setup. My question is, what is a good thickness for the rings? Stewmac has them (flat bottom) at 3/8" or 3/16" and Grizzly has them at 0.082" thick. What's the thickest I can get away with? Believe it or not, I do not currently have any kind of measuring device avaiblable.

-

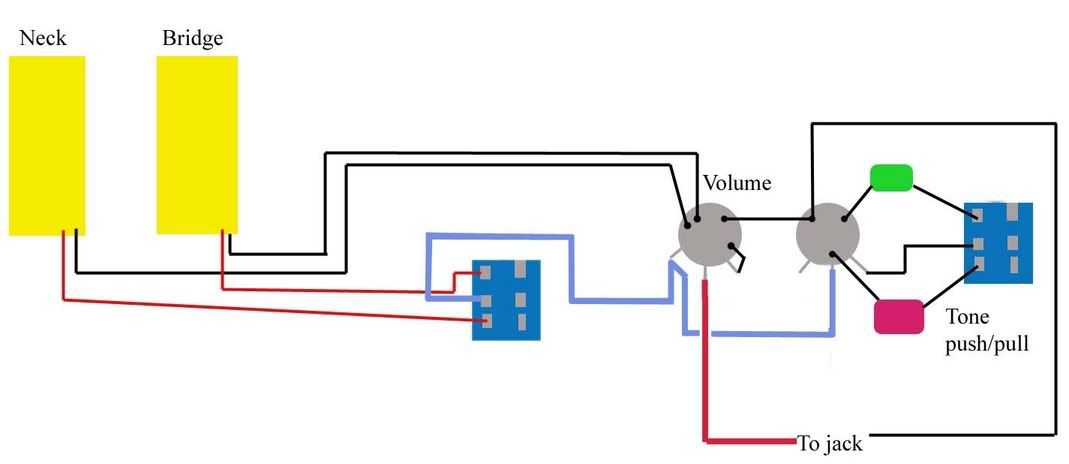

I think this might be what you're looking for

a tech helped me draw it out for what I wanted and then I just modded it to fit what you wanted.

Black is ground, though I didn't draw in the ground wire that goes to the bridge

EDIT: I don't know how p90s are in terms of the wires they have coming out of them so this might not be entirely accurate.

-

Those look really nice. I'm considering this finish partly because I don't have the equipment to spray a nice lacquer finish and partly because it looks nice.

And I do have some more questions

Since the oil is soaking in do I have to worry about it building up in the neck pocket (if that did happen I could just sand it out, right)? Do I need to protect pickup and control cavities...like will the oil finish in the control cavity interfere with shielding tape sticking to the wood?

Wet sanding is dampening the wood (which would be better in this case - water or a solvent) then sanding with the grain, then wipe the slurry across the grain?

Can you give me an estimate of about how much of the mixture I'll need to submerge the guitar?

Thanks for your help.

-

you'll see in that thread that i usually use an older version..equal parts of linseed oil, turpentine and varnish. you can substiture poly for the varnish and even paint thinner for the turpentine. whatever mix you use mix it up the night before you use it and let it blend overnight. get yourself a stick that you can screw into the neck pocket with a hole in the other end so that you can hang it from the ceiling or a pole. totally flood the surface and let it sit for 15-20 minutes. wipe it down well and then apply another coat. another fifteen minutes and wipe it down again.

after the first two coats add additional coats the same way but let them sit overnight between coats. you can wet sand with 400-600 grit wet/dry paper between the first two or three coats. after that you're defeating your purpose.

just keep adding coats until you get the feel and patina that you're looking for. after it has cured for a few days you can apply a good paste wax intended for floors..not cars.

it gives a nice medium sheen that allows the feel of the wood come through and can be renewed if needed with anther coat of wax.

good luck.

Thanks. I would've thought the initial soaking of the wood would take longer than that. I'm guessing if I finish it with this method I won't need grain filler b/c the oil mixture totally soaks in and the urethane polymerizes to seal it?

-

I just ordered some black limba from Gilmer Wood and spoke with Marc (their instrument-wood guy) and he recommended using a 1:1:1 mixture of linseed oil, turpentine, and polyurethane.

Has anyone tried this? It sounds like what's going on in this thread

http://projectguitar.ibforums.com/index.ph...3&hl=turpentine

but is maybe a little harder/offers more protection?

And would ever have to reapply something like this down the road?

-

I just restrung my tele with the same gauge strings as were previously on there (replaced them one at a time) and now the A and low E strings buzz (even when fretted). Does this sound like a truss rod thing or should I simply raise the action a little.

-

-

that is beautiful

-

I think it looks good. I like the fretboard (excepting the inlays).

-

Check out Modulus...their basses have carbon-fiber necks.

http://www.modulusguitars.com/v2/products/quantum/index.html

-

I think 2" total is more reasonable. I would leave the maple where it is and take the ash down to 1.25". On another note, I havent seen too many ash backed, maple topped guitars. I am not sure what type of sound to expect from that combo.

I think some Warwick basses use ash back/maple top

-

If you can purchase from a chemical supplier, borax is sodium borate decahydrate (also goes by: Sodium borate; disodium salt; Sodium tetraborate; Sodium tetraborate decahydrate; Disodium tetraborate decahydrate).

borax is used to break the surface tension of the water so that the paint can swirl around, so if you can't get it from a chemical supply (or maybe ask the chemistry department at a university), you *might* use something else to break the surface tension like a dye-free soap (mix gently to avoid bubbles).

EDIT: The soap method probably won't work for staining/painting swirls....it will break surface tension though.

-

If your neck fits perfectly right now then tape over the inside surfaces , especially the face (where the mounting holes are), before spraying. If I found my neck fit was a little on the loose side I might try to make up the difference with paint, but just around the sides. For all other cavities it doesn't matter. I usually just shoot away, at least the inside wood will be sealed.

Thanks! Since it doesn't matter I'm gonna assume I could use grain filler to protect it a little rather than lacquering?

-

So then the neck pocket (and cavities) don't need to get sealed?

-

I saw on this thread that Drak is going to spray lacquer in the neck pocket. If I'm going to use an open grained wood like korina would I have to spray the neck pocket/pickup and control cavities or would just grain filler do the job?

-

Find the guitar's serial number (my jazzmaster has it on the neck plate).

Then go here: http://www.fender.com/support/dating/fender_us_dating.php

-

How about if you're going use a single coil and a humbucker with one volume and one tone knob? Still use 500k's?

Matching Black Limba

in Inlays and Finishing Chat

Posted

I'm going to have a black limba body with a maple neck and was thinking about finishing the neck to match the limba. I was thinking using a minwax stain on the maple and then finshing it with a mix of boiled linseed, turpentine, and polyurethane. Would that work or would I have problems with the oil over the minwax?

Any alternative selections or better ways to match the maple to the limba?

Thanks.