-

Posts

269 -

Joined

-

Last visited

-

Days Won

20

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Robbinst

-

-

Hey guys I have about five builds going at the moment that I would like to show you but it would been unnecessary to clutter the forum with a thread for each. Instead I thought it would be better to put all my stuff in one spot like a few others have done. I will also continue builds from other threads here.

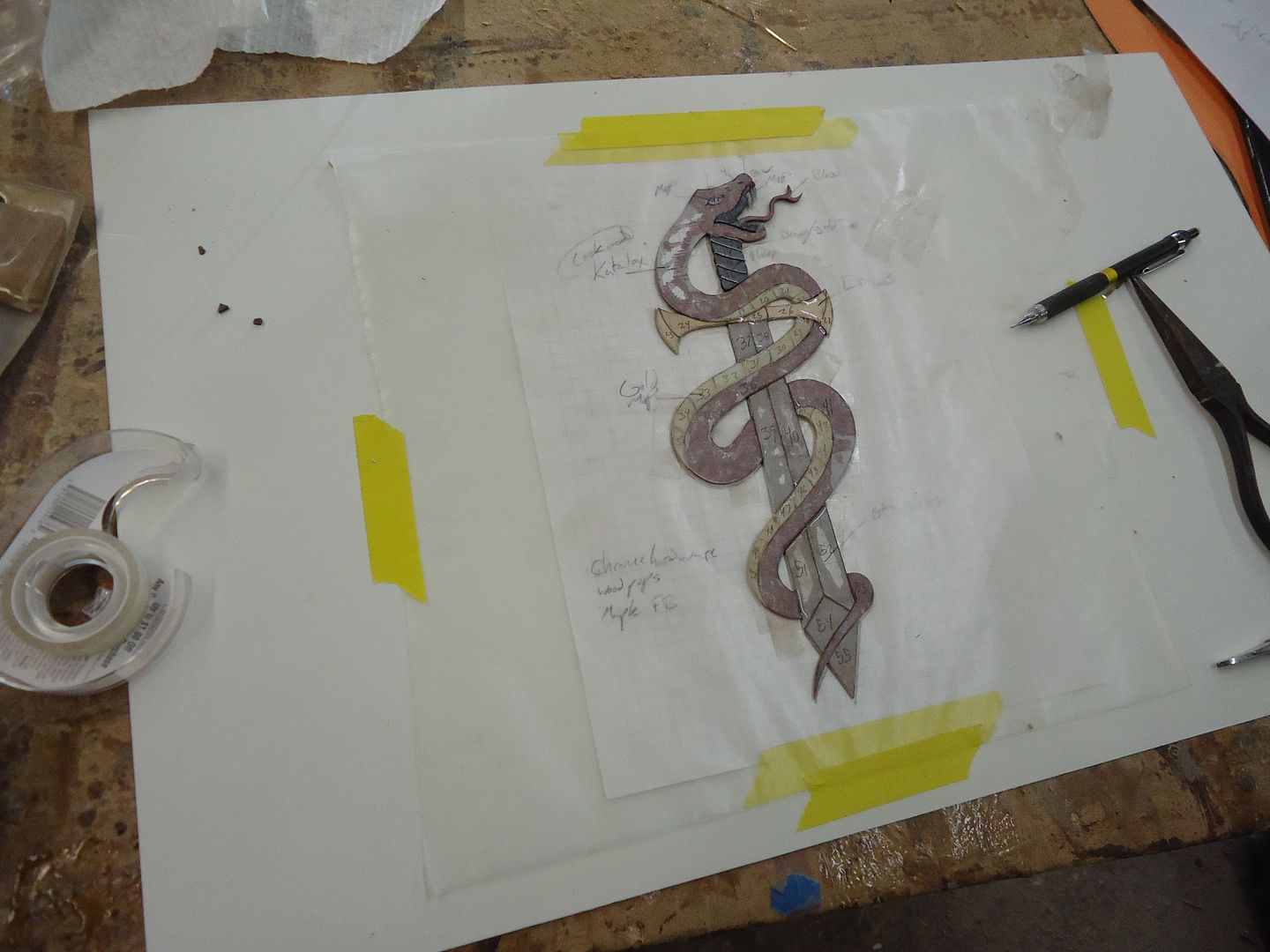

Here are a few builds I have been working on. The one with the laminated body is particularly special to me because it is being built for my dad. It will include a 58 piece inlay on the back of his snake tattoo that he got in memory of his own father.

sappelli body and neck with curly maple cross laminations!

korina body, myrtle wood top, paduak fb

-

^ Its my favorite as well! I'm almost sad to sell it but the happyness of the customer will make it worth parting with haha.

-

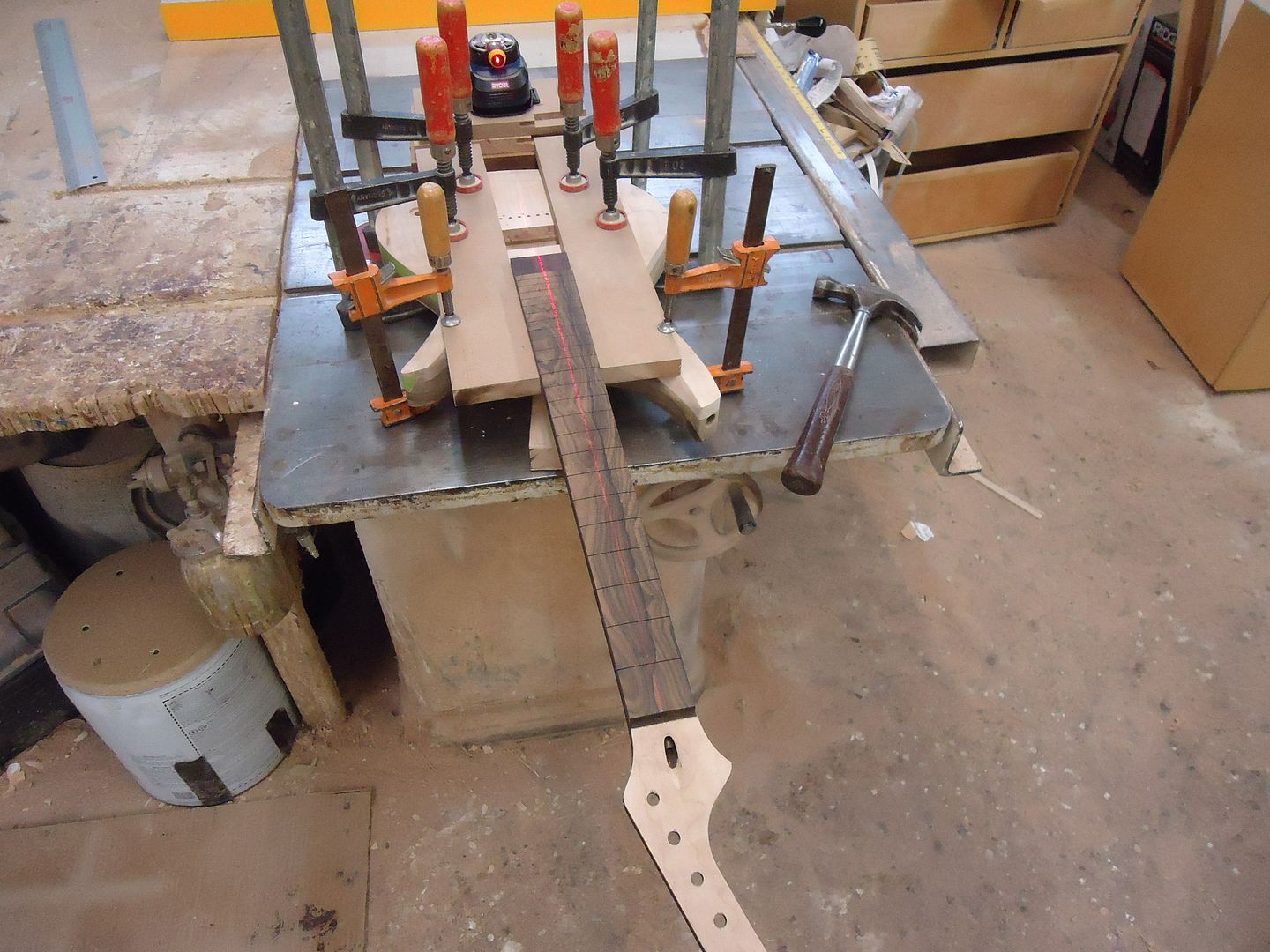

The neck is glued and the heel transition is carved, its very comfy.

I'm putting my sig on the truss cover for this one because of the small headstock shape. The raven lost his usual spot but I decided to perch him on one of the rear tuners instead.

Small epoxy smudge on the six string's headstock that I didnt get to sand off today. Ill take care of that tomorrow morning then begin the sealing/color/sealing/clear process

-

2

2

-

-

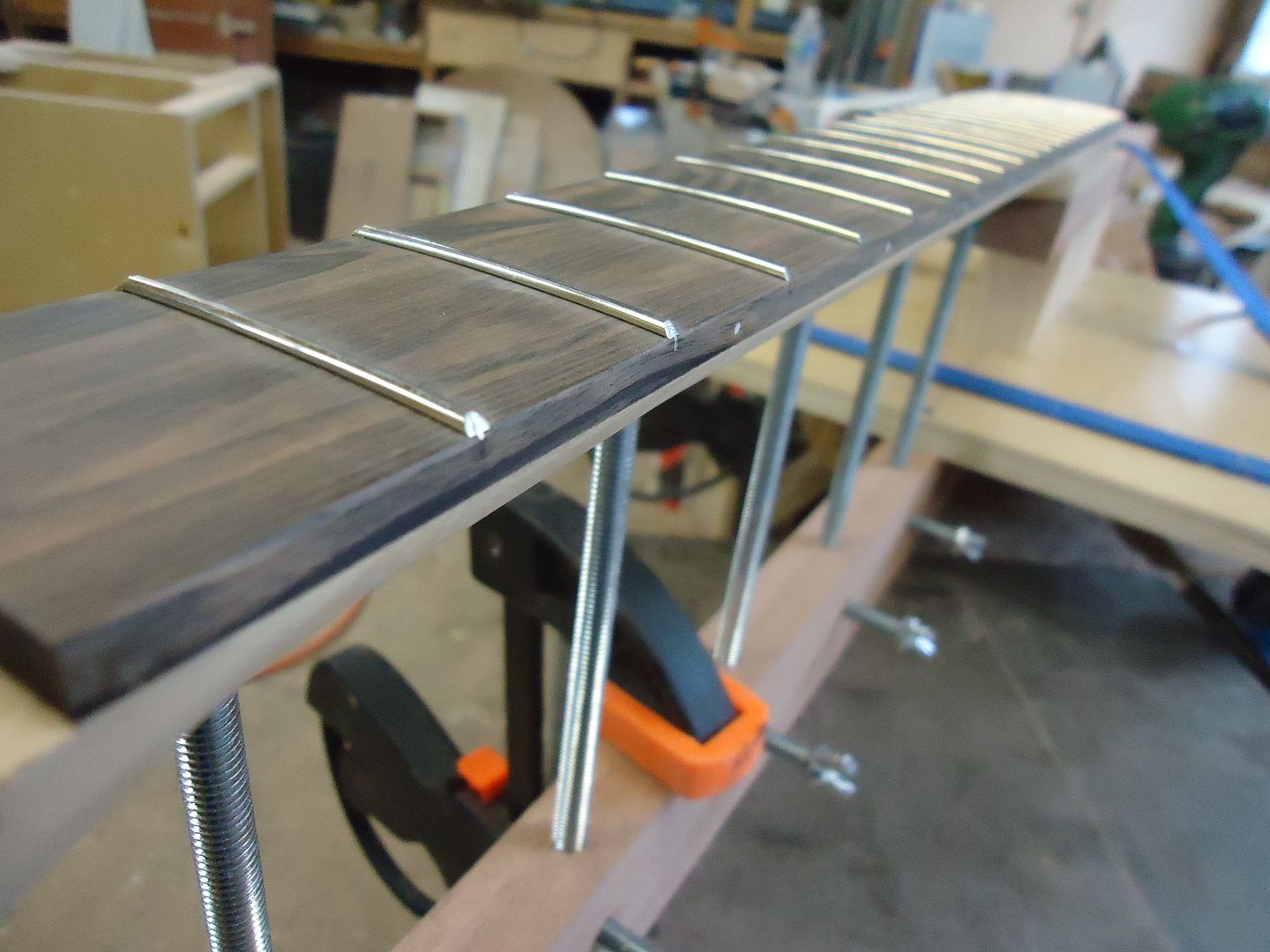

Took some time this week to make a neck jig to improve the accuracy of my fret leveling. It works quite nicely.

-

haha I wish it was mine. Thats Daemoness. I love his inlay style and hope to get to his level someday. Here is his page

-

I deffinitely wouldnt give up my spiral cutters in exchange for these.The main draw to these thing for me was the size. I'm trying to get more intricate/exact with inlays and some times the 1/32nd is just too big. I'm hoping they will be able to handle cutting thin lines and cleaning up points so I can do more accurate lettering or stuff like this

I'll giv'em a shot and let you guys know how they do

-

Thank you both!^^

I wasnt sure if this deserved its own thread in the inlay or tools forums but I just wanted to let you guys know about something I stumbled upon earlier.

I found these cutter heads while looking into wood engraving stuff. If any one does really intricate inlays but dosnt want to pay twenty bucks per bit from stew mac, this sight has a set of 10 very tiny bits for $15. I have not tried them as of yet but I think I will due to how inexpensive they are. Stewmacs smallest bit is 1/32nd (.8mm) while this set includes .7mm and .6mm so you can get even more detailed cuts for a fraction of the cost. Hopefully this can save some one a few bucks!

http://www.profitablehobbiesstore.com/larger-cutters-3/32/square-cross-cut-bur-set-3/32/

-

Frets, side dots, truss covers, and rough neck carves

My sig will be on the truss cover on this one because theres not much room else where on the headstock

Ebony raven inlaid to compliment the ebony buckers and other black hardware

-

Wow, they're both lookin awesome! Black limba and black&white ebony - two woods that I always wanted to try but can't seem to find any reasonalbe source in Europe..

Thanks! I really love the black limba its gorgeous to look at and a pleasure to work with, I definitely plan on using it in more of my builds.

here some lumber sites with an assortment of different size limba, prices arnt too bad but I am not sure what shipping will be like.

https://www.gilmerwood.com/items.php?species=Limba&CID=31

https://www.cookwoods.com/lumber-site/?s_cs=1&s=black+limba&x=0&y=0

http://www.byoguitar.com/Guitars/Black-LimbaKorina-Body-Blank__BYO-BLANK-BL.aspx

As for the sanding issue I was worried about:

I checked out my dads body work supplies and found he had some stiff durablock foam/rubber sanding blocks. He was nice enough to let me use them for a bit and I gotta say they worked great! The Tops are dead flat and the carves are as smooth as can be. I was sad to have to return the blocks so I went on amazon a found a 7 peice set for about $34. This may or may not seem expensive to you but after testing them I think its worth the price. They will last a very long time (my dad has had the same set for years even though hes working and sanding multiple cars daily).

This is the only set I found at this price, the others are $45 and up for the same blocks. Theres 17 left in stock so if youre interested check it out soon!

-

1

1

-

-

Thanks HC, I do appreciate it!

Figured out the colors for the seven and duality based guitar on some scrap wood

seven- version of a lagoon burst, blue to natural burst

duality- red/pink to violet burst

-

looks pretty much like Vik Guitars´ duality series to me.. but nice clean work!

Yep thats the idea haha. I really like the shape and the way it flows. I have a new respect for Vik if he is hand carving each one, its definitely not easy.

HC- That does look like a good spot for some sort of flame thrower/ morter launcher haha

-

Awww man! I hate when I get to last picture when its so close to being done. My thought process as I scrolled was= awesome...Awesome...AWESOME...dam!t. Haha keep up the good work!

-

Thanks for the info Scott! I'll try and find some sort of rubber material with the stiffness/ flexiblity I need. My dad does body work on cars so Ill have to go raid his toolbox haha.

Wanted to make sure the straplock wouldnt just rip out of the thin horn so I burried it a bit

All carves are now roughed in, still needs a bit of clean up but the hard parts done

-

Beautiful work man, very clean!

-

So I have a question for you guys. With the last build I did using quilted maple my finish came out alittle wavy because of the grain. Certain spots are softer and sand quicker leaving the harder grain raised. I know I can fix this with extra time with a decent size sanding block on the flat parts but the carves on this one are worrying me. I have rubber spindles with 80 grit on them from my occilating sander that I was using but due to such a small area of contact when sanding I think I'm just going to be following the waves in the grain rather then flattening them. I have a good scraper fresh from stewmac but the grain makes it very difficult to pull an even carve with it. Is there any tricks I might be missing that would help?

-

1

1

-

-

This one has really extensive carves, at least compaired to anything I done as of yet

-

1

1

-

-

Well guys I messed this one up to the point were I didnt feel comfortable sending it out so I talked to the customer and decided to do a version two along with a second build that he wanted which is awesome! The second build Is based on a Vik Duality with a black limba body, quilted maple top, rosewood neck, munn ebony fb, custom maple humbuckers and finished with a violet to red burst.

Heres some pics of where Im at now:

This wood blemish looks like an apple

-

Was not expecting the blue trem, thats sick though!

-

^Thank you!

-

The blue does seem really out of place but I dont mind it as much as I thought I would. Its growin on me. Cant wait to see more pics, especially once the neck laminations are carved to shape!

-

RAD- The arm was built by my dad. I want to make a jig that can carve a neck accurately and repeatably so I needed the over arm router but they are way too expensive for me at the moment so we designed it and he welded it up. I need to figure out the rest of the jig and then I will build a secure table and stand for the arm. Body thicknessing was not the intended purpose but it works for now.

Zed- If you a refering to the blue face of the body, that is a western maple top, and was choosen by the customer for its grain pattern. It is very thin and I'm not sure if it would have a noticable affect on the tone. Also welcome to the forum!

-

The colors and size definitely give it an incredible hulk feel. Very nice sir!

-

Loving the progress so far! What did you use for the black part of the logo? Ebony with etched lines and a white fill?

-

Getting the body down to about 1 1/4"

REALLY? Do you not like your appendages?

Sorry, It is really none of my business if you disregard safely. However in the future for the impressionable nOObs that come here to learn how to build guitars I ask that you note when you do things in an unsafe manner.

I appreciate your detailed threads and I hope you continue to contribute to the forum.

I do appologize. This is a dumb way of thicknessing boards but its what I have to work with for now. I have done other bodys since and now use a method cutting in sections that keeps my hands away from the bit at all times. I would not suggest anyone attempting to immatate this process as it can be very dangerous.

Robbins Guitars Thread

in In Progress and Finished Work

Posted

ash body, walnut top, maple neck, and a cocobolo fb

Gonna be late for work! I'll get more pics soon!