-

Posts

437 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Robert Irizarry

-

-

A friend of mine sent me this. I certainly need at least one. We could start a list of everyone who is as much in need as I am, and maybe get a bulk discount if we can discover who makes them

Denis

You think I can string a couple of these together so I can be twice as good? Oh wait - basic math - 2 x 0 = 0.

Regards,

Robert

-

yeah, i was planning to be fairly conservative with whatever i use. most of the spots are on the body edges, which will be getting sanded down anyway. i figured i'd fill the holes and then use something to get most of the excess off before it hardens

Good idea being conservative with its application. Just a note - the System 3 guys make epoxy that's used for building boats and the stuff is FAR stronger than wood itself. In fact, it can fill significant gaps without a loss of strength.

Regards,

Robert

-

Ah - as it happens I tested playing positions earlier today on a cardboard mockup! I have posted a series of pictures on my blog http://guitarworks.thestrandbergs.com/ and in particular the classical position (guitar resting on left leg) was incredibly comfortable. This is not the position I normally play in, so that was interesting.

Interesting observation about classical position. I found the same with my Klein based project guitar as well. Unfortunately, the real Klein places the output jack in an inconvenient location for playing in classical position but I remedied that by moving the jack to the surface.

In classical position, the guitar sits up beautifully with no effort. You can actually remove your hands from it without a change in position. It also mimics standing position more closely than a casual seated position with the guitar more centrally located on the guitarist's body.

Regards,

Robert

-

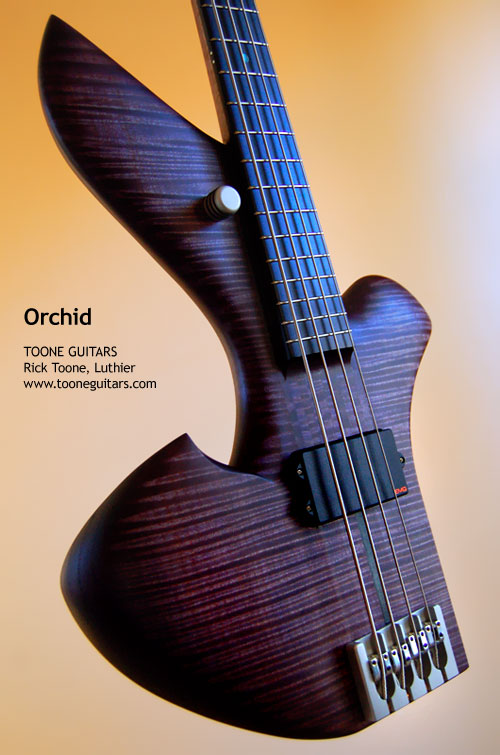

Let's add another - Check out Rick Toone's Orchid bass guitar and its unusual trapezoidal profile neck.

Regards,

Robert

-

I would hate having the vol pot in that position too. I think my hand would catch on the edge of the fingerboard when trying to turn the knob.

Pity, cos I really like the overall look of the thing!

DJ

It's a custom guitar so I'm sure the builder can accomodate a different location.

Regards,

Robert

-

Here's one for you:

The Orchid Bass Sprouts An Unusual Neck

And since no post is complete without image goodness, here you go:

Regards,

Robert

-

I really like my Dewalt DW618B3 3 base router kit. Excellent quality all around and I've used it in a homemade router table.

Regards,

Robert

-

When I needed a small CNC'ed mini mill to make a fret bender I spent many hours on the CNCZone site. There is a section on Router mills and Guitar building. The site is big and the two sections are not combined. I found the hardest part with the whole project going from having all the mechanical parts to creating a part. Design to G-code, if that didnt make sense you have a long journey ahead of you. Anyway thats the right site and good luck to you.

I'm definitely at the beginning of the journey. Right now it's a thought but I'm a fast study, focused (some would say obsessive) and happen to work in Information Technology. It just seems like a natural fit for my technical background. I appreciate the feedback!

Regards,

Robert

-

Here are some samples and the machine itself. I find it is faster to bansand and sand the perimeter rather than machine it out.

Thanks so much for the pics as well as the tip! My wife is already starting to dread my talking about building one.

Regards,

Robert

-

OMG - Love the shark!

Regards,

Robert

-

Marty: Would you happen to have any pics of some of the work you've done in CNC?I hardly use my hand held router any more, I just draw and rout from the CNC right to the body blanks. MartyRegards,

Robert

-

Many thanks for the feedback, Marty! I'll be digging into the CNCzone site shortly.Robert,I bought plans from John Kleinbauer at Crankorgan.com. This was before the CNCzone started up. He has many different type of machines that are built from hardware store parts. Once that was completed I had the knowledge that I needed to build something of my own design that could accomodate necks and bodies. I'd go that route again if I had to do it over. You'll see many of John's design elements incorporated into other machines designed by many people on the CNC zone.

Marty

Regards,

Robert

-

It's really too bad, though, as they had some nice headless stuff for a pretty decent price. I'm currently waiting for a reply from ETS hardware (also German) to see if they can provide what I need. Bit pricier, though.

Truly a shame. As far as ETS, I tried contacting them a while back and never heard from them. I hope you have better results.

Best regards,

Robert

-

I've been toying with the idea of building a CNC router and was wondering if anyone here has experience with them. I only recently started digging around for resources and came across Cnczone.com which looks to be an excellent resource - it even has a musical instrument section. Any suggestions on resources, recommendations for plans, experiences you care to share, etc?

Thanks in advance!

Regards,

Robert

-

-

Very interesting! I'm looking forward to watching the build. As much as I like headless guitars, I like where this is going.

Regards,

Robert

-

I was asked if I knew of any material that is pliable, can be bent into any shape but is stable enough to retain its shape so that a guitar plan could be drawn on it. Basically, it would be for experimentation...

Any thoughts?

Regards,

Robert

-

i think for some people weight is a real issue and we really have to commend yamaha for trying to do something about it and actually trying to move guitar design forward in that respect. I dont think these will appeal to most but i reckon they will have their own collectors in a few years time.

+1 - Weight should be a serious concern for anyone with back problems or other forms of musculoskeletal disorders (MSD). And with the exception of the air tube silliness, this should be a simple approach for building a light weight guitar.

Regards,

Robert

-

Welcome Kenny! You've come to the right place!

There's tons of information here and a good bunch of folks.

There's tons of information here and a good bunch of folks.Best regards,

Robert

-

I think my next puter will be a Mac....I hear good things and I hate my dell.

I use Windows, Mac and Linux and Macs are indeed nice but each is a different experience. This is all opinion but ... Macs have a more integrated feel to them. It's almost like buying an appliance. You don't hack your appliances. You turn them on and they go. Windows is kind of somewhere in the middle trying to be more integrated in the way it does things but still accessible and then Linux, despite great advances in usability, still feels like a tinkerer's delight.

In any case, you'll need some ramp up time to get used to a Mac and hardware tends to be pricier as well. Don't forget to consider that you'll need to replace any software you now have on a Windows PC with versions that will work on a Mac. You may also have to deal with compatability issues with files being moved between Mac and Windows although this isn't the problem it once was.

I'm not trying to discourage anyone from Macs, btw, just pointing out some stuff that isn't always obvious to folks when they start talking about a major switch...

Regards,

Robert

-

I'm waiting to find out more from Hohner about the mechanism they use for the leg rest. I'm very interested in seeing how they went about engineering it.Looks neat. I've had similar ideas before (a better "lap bar" compared to the Steinberger "brooms") but this is way out there. Awesome.For others - here's a pic of the Hohner with its leg rest deployed:

Regards,

Robert

-

I just came across this guitar over the weekend and thought some of the folks here would find it interesting:

The topic title says it all...

Regards,

Robert

-

Black Machine makes their guitars super thin at 33mm with bolt on necks. I think you're safe.

Regards,

Robert

-

How do you like that bridge?

Regards,

Robert

Ergonomic Guitar Build

in In Progress and Finished Work

Posted

+1. I'd love to see another source for headless bridges. Musicyo rarely has stock of the R-trems, the Trans-trems are all but unavailable and ABM is out of business.

Regards,

Robert