jammy

-

Posts

743 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by jammy

-

-

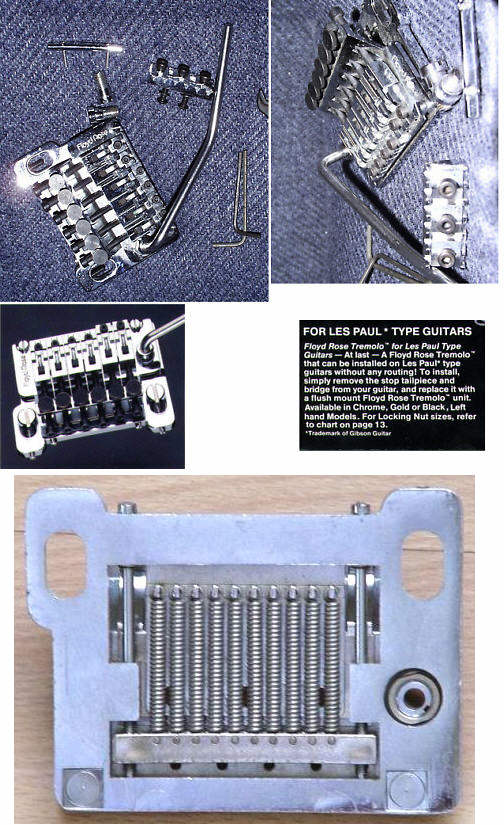

That's what you need. Fits over normal TOM studs and has springs built in.

Floyd on a les paul with no routing

-

How does it sound?

Congrats mate

-

Don't get me wrong, I plan to make one too! I'm glad I've done a few "by hand" though.

-

Are you working in a mould?

Side bending isn't easy! Just take your time and be systematic.

My first set of guitar sides took me 2 full days to get perfect

-

What do you plan to do about your headstock/break point? (the place where the headstock face and the neck face meet)

I'm working on a fanned fretter at the moment, and it's taking alot of thought! I've ended up deciding that to get the break point at an angle (the angle that the nut will be at) I'm going to have a twisted headstock, it'll kick back, but also twist past the nut.

Just wondering if you were planning on doing something similar, or if you've thought of something simple that I've missed!

I don't think you'll need to break the neck at an angle, the string shouldn't hit the excess on the high side. I was going to use extra wood from my headstock cap and cover the excess...............or if you check out ThirstyGums fanned fret he just put the nut on like it was a fret and left the finger board all the way to the break.

Oooh not neat enough for me

Looks like an afterthought or something. I'll post some pics when I come to do mine, we can compare notes!

Looks like an afterthought or something. I'll post some pics when I come to do mine, we can compare notes!

-

As they suffer from the same problem as these fine filter extractors - some very fine dust is blown back out into the atmosphere.

He reccomends that you should spend time/money on getting your extraction system right, saying if there's enough dust in the workshop's air to warrent a cleaner, something's wrong

-

I've read that cover to cover, and bought the dust extractor specifically due to it's filtration capacity (0.5 micron)

I was considering an air cleaner too, but from what I've read in that book they're near pointless

-

That's freakin ace! Congrats

-

I'm not sure what's going on with that dust collector, but.....if you can find a way to direct the outflow from the filter bag outdoors (so that the air is not blowing into your shop) you'll save yourself some potential long-term damage to your lungs.

These portable dust collectors do a pretty good job of filtering, but their efficiency at trapping stuff thats smaller than a few microns is not good at all. Just get one going on a sunny day and watch what floats out into the air through the filter. That's the stuff that will get stuck in your lungs and turn into pneumonia, emphysema or cancer down the road. You either need some ventilation to get that stuff out of the shop, or a good air handling system inside the shop to cycle the air and filter that stuff out with HEPA filters.

It's a fine filter extractor, so I shouldn't have a problem. I'll post more pictures when I've got it mounted up on the wall (hopefully this evening)

Another little bit of progress - just ordered £130's worth of cutters for the pin router. Solid Carbide

-

What do you plan to do about your headstock/break point? (the place where the headstock face and the neck face meet)

I'm working on a fanned fretter at the moment, and it's taking alot of thought! I've ended up deciding that to get the break point at an angle (the angle that the nut will be at) I'm going to have a twisted headstock, it'll kick back, but also twist past the nut.

Just wondering if you were planning on doing something similar, or if you've thought of something simple that I've missed!

-

REGAL ACOUSTIC GUITARS

These early acoustics were distributed by Fender from the mid to late '60s. They used laminate construction. There is very little detailed information on them.

That's from fender's website. Late 60's sub $100 guitars.

-

Last 2 power tools arrived!

Last 2 power tools arrived!

That's the edge sander/linisher.

Allready had a piece of wood firing across the workshop during testing

http://www.solar.myby.co.uk/misc/andy/dustextractor.jpg

And this is the 2000watt, 2 motor dust extractor

-

So you all have more money now than you think you will have after college?

Definatly.

At the moment living at home makes for a super cheap lifestyle!

When I start making some money and actually come to move out I fear I'll be far more skint.

As for the workshop - Expect some updates tonight guys

-

I'm in Rainford, near St Helens.

You're more than welcome when the workshop's finished mate

-

The sanders now in pieces for me refurb/clean.

All looks in tip-top condition though

I'm chuffed!

I'm chuffed! -

Yes, that's the plan.

I'm setting up now while I've got the cash and I'm still in college to give me an oppertunity to ease into the working life.

Really looking forward to it though!

-

-

Really nice guitar you've got there. I can't wait to see you apply your skills to a fanned fret 8 string.

Question though - I've read a few different ways to do fanned frets, but i was of the same mind as Jammy where the 12th fret is totally straight and considered the midpoint of the fan.... is that what you're doing? I'm just trying to understand methods for fanned frets as i'm considering attempting it.

You can keep any fret you want level.

Decide on 2 scale lengths, decide where you want the level fret and line the 2 scale lengths up at that fret.

-

I like it, though if it were my choice I'd go for a longer scale on the bass side. What are you tuning it to?

Also, why did you choose to have the points where the frets come level so low down the neck? On the fanned acoustic I'm working on at the moment everything's straight at the 12th fret, and drops evenly each side of that

-

Or, forget the belt sander.

Really, they're expensive, dusty, noisy, and they do *nothing* which can't be done better with a plane and a straight sanding block. If you can explain what you want that a plane (handplane) can't achieve, I'll tell you how to get it, but right now you're trying to find a *very* expensive wayto do a job which is better accomplished with a pretty cheap tool.

I can see where you're coming from, but I must say I don't agree.

How would you suggest sanding the edges of an electric guitar body with a plane and a sanding stick?

Sorry to gist, but you see my point

After further research I've found a pretty cheap unit which has, for accuracy, a replacement graphite backer for the belt's working face, could be worth a look...

-

Do you think so?

I've used the long belt sander at college and it can get stuff flat - flat enough to suction stick to the cast iron tables.

That was a pretty expensive one, but nothing too impressive.

I can't see how, if there's a uniform 80 grit paper running over a flat surface of steel how it could fail to flatten something? Should just be a mechanical version of your paper stuck to a level.

A handplane is always an option, indeed. I suppose even a small surface planer would do it if the sander's a no go. I was hoping to mechanise the procedure though.

-

It has to serve many purposes as it's replacing everything I use the disc sander for at college soo...

-Sanding Convex shapes (wether it be an electric guitar body, acoustic guitar top/back etc...)

-Sanding things to size after cutting (say the blocks for an acoustic, edges of fingerboards)

-Flattening things (the front of a neck blank before glueing on the fretboard etc...)

The thing which will be the most demanding is the flatteneing, I would think - it's got to be very flat, and large enough to work on the whole front of a neck blank at once.

-

Well I need a little more advice from you guys.

For sanding profiles and flattening faces in college we use one of the 2 wadkin 30" disc sanders - they're great bits of kit, but seems to run about £4500 and are three phase...so not really a goer for the home workshop

I've been looking into oscillating edge sanders as an alternative, but searches are turning up little choice at the cheaper end of the market. There appears to be the axminster one, then another couple around the £700 mark, then little else. Does anyone know of any manufacturers/stockists that I may have missed? Or can you reccomend an alternative tool to do the same jobs?

Cheers for any help, as always.

-

I use a no7 plane and a shooting board - I can get a board ready to join from a rough edge in about 5 mins.

Remeber the joint is far more important on the top as the wood's lighter and lines are easier to see.

My Workshop Progress Thread

in Tools and Shop Chat

Posted

Bingo!

He reccomends sanding tables alot