Strandberg Guitarworks

-

Posts

129 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Strandberg Guitarworks

-

-

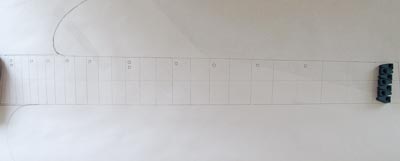

So, slight change of plan... As I am building this guitar (now called #6) along with a custom order by Chris Letchford called #5, I will make this also a fanned fret 7-string, 25.75 – 25″ scales. But, it will have a trapezoidal neck profile and the cavities in the body will be made differently. #5 will have cavities routed from above and a top glued onto it like my other EGS guitars. #6 will have cavities routed from the inside edges of the sides. I have never tried this in practice, so it somewhat of an experiment.

So, a little progress has been made:

See the other threads for more info.

-

Yes, Chris is definitely an accomplished player and tours with some interesting folks as well!

So, here is a bit of progress:

A swatch for of: rosewood fretboard (that looked a little too purple at first, but better when oiled), wenge for the top, mahogany for the back, maple for the neck blank, custom colored blue hardware and Lundgren M7 pickups.

And lastly, some new routing templates.

-

This guitar (which will have serial #5 although being called 4 here) has been purchased by Chris Letchford of Scale the Summit, so he has gotten to decide the final specs.

- 7 strings headless EGS design

- Mahogany back with maple neck-through-body center

- Wenge top

- Semi-hollow construction

- Belly carve + arm bevel

- 2 x Lundgren M7 pickups

- 2 position mini-toggle switch (neck/bridge)

- Master volume, master tone

- EGS fixed bridge, custom color blue

- String spacing at bridge 10,5 mm and nut 7 mm

- Rosewood fretboard

- Stainless steel Medium/High frets

- 24 frets

- Double-acting truss rod

- Zero fret

- 25.75″ - 25″ scale, with neutral fret at approximately fret 9 (12 mm difference between outermost bridges)

So build has been started finally!

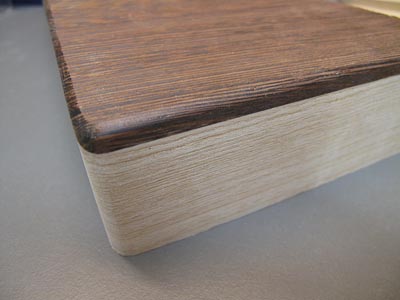

I got some very nice wenge for a top similar to my #3.

- 7 strings headless EGS design

-

-

I will be in London (around Canary Wharf) between the 7th and 9th of June. If you are in the London area and would like to take one of the EGS guitars for a spin, let me know and I will bring it.

-

The f-hole actually took a lot of effort to design. It has several purposes:

- it is a play on my logotype, with the '.' and '*' in .strandbergGuitarworks

- it shows that the guitar is semi-hollow

- it is a decorative feature

But having said that, I am very happy with the non-f-hole look. I just have to find another way to get my logo/name onto the instrument. I have ordered custom neck plates engraved with my logo, and will sign and number inside the neck pocket.

Having an f-hole and putting a label inside, would be pretty cool....

-

Some more sound samples being uploaded as I am writing this. #2, which is the maple top, mahogany back, "normal" profile maple neck with the sound channels is becoming the majority's favorite. A lot of people seem to think that PAF pickups with really dot the "I" so will try that. I am torn between #2 and the wenge top one (#3). I like the look of #3 guitar the most and have entered it into Guitar of the Month for June, so be sure to vote!

Tremolo is very stable, but Squier nut not so good with the current gauge of strings. I will fix and post some abusive samples.... I have had the same thought as Geo suggests and need to replace the whole Squire neck anyway since it is not really stable in shifting weather conditions, I just noticed.

Just one pic of each, finished:

#1

#2

#3

#4

-

Here is the second installment in the Ergonomic Guitar System.

Build thread is at http://projectguitar.ibforums.com/index.php?showtopic=42643.

Specs:

Body Material: Swamp Ash Back, Wenge Top, Book Matched

Body Characteristics: Semi-hollow, Solid top, Rounded edge

Finish: Watco Danish Oil

Pickups: 2 x Lace Alumitone Splittable Humbuckers

Switching: 5-position lever with the following positions:

1. Neck

2. Neck w/ Treble Roll-Off

3. Neck + Bridge Parallel In Phase

4. Neck + Bridge Parallel Out Of Phase

5. Bridge

Wiring: Master Volume

Knobs: Ebony

Bridge: EGS Series 3 Black/Black

String Lock: EGS Series 3 Black

Neck: 3pc Wenge Laminate, Trapezoidal Neck Profile

Fretboard: Ebony

Fretwire: Jumbo

Truss Rod: EGS Carbon Fiber Spinal Truss

Scale: 25.5” (bass end) – 25” (treble end) 22 Frets

http://guitarworks.thestrandbergs.com/wp-c...nt/img_2534.jpg

http://guitarworks.thestrandbergs.com/wp-c...nt/img_2535.jpg

http://guitarworks.thestrandbergs.com/wp-c...nt/img_2536.jpg

http://guitarworks.thestrandbergs.com/wp-c...nt/img_2550.jpg

http://guitarworks.thestrandbergs.com/wp-c...nt/img_2552.jpg

I have links to lots more pictures and sound clips on the build thread.

-

Thanks for the discussion - I am enjoying it a lot!

As for neck sound comparison, the plan is to rotate the necks across the different bodies and try to record the same thing with each for comparison. Just have to find a slot in the schedule and a guitarist patient enough....

Cheers,

Ola

-

Videos/sound clips are up - check my site!

Pauliemc, the Rick Toone neck utilizes the Toone-Townsend solid neck core, but mine are all adjustable:

- the Wenge neck has a 15mm OD/12 mm ID CF tube with a single truss inside, mounted asymmetrically at the bottom of the tube

- the Maple neck has a Martin style aluminium truss rod and is reinforced with CF in the laminates

- the last neck (on the f-hole guitar) is a Moses Graphite neck, adjustable in the heel end.

The Wenge neck seems a little brighter and the Moses neck a little warmer with the maple in between, but that is very preliminary. Seems like air channels make the neck respond very quickly, but that is again preliminary. Check out the sound clips and see if you can make any educated guesses :-)

-

They're all very fine looking instruments, Ola. I really like the far right instrument's "f-hole" decoration. Was there much of a decision-making process behind placing the neck pickup slightly further back than the model without the "f-hole"?

Thanks Prostheta! The far right guitar (with the f-hole) is the original prototype build. When I made the follow-up builds, I moved all the pickups slightly towards the neck for a slightly meatier sound. Since the objective of these builds was to only vary one option (materials), I guess I broke that rule slightly...

Nevertheless, the necks all have the same heel, so I can rotate the necks to explore the impact of neck material options on each of the guitars. I look forward to that a lot!

Oh, a regarding visit - make sure you plan to include Uppsala and not Gothenburg in June. I'd enjoy meeting up.

-

I had an awesome time in Gothenburg over the past weekend. I will post high-res images of the builds shortly, as well as sound samples. In the meantime, here are some pictures from the show.

All four guitars have turned out amazing and received very positive response.

-

I'm exhibiting at FUZZ Guitar Show in Gothenburg next weekend, so have to build more than just guitars... Today, I built a stand for them - included is my previous prototype guitar.

Some work remaining as you see, so it will be a long week. Do swing by Gothenburg if you can and come and say hi!

-

Stratesque body almost finished...

-

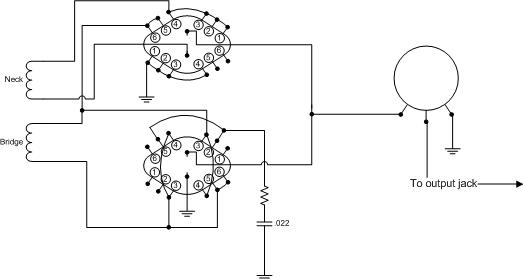

Lots of progress since last post... First of all, feel free to proof-read the schematic for the switching of the maple top:

- neck

- neck with treble cut (adjustable through hidden pot)

- neck + bridge parallel

- neck + bridge parallel out of phase

- bridge with treble cut

- bridge

Hanging to dry:

Checking neck alignment:

Shielded control cavity:

More pictures on the site as always!

- neck

-

Well, there ain't a cloud in the sky above Uppsala so I bet you got your spraying done!

You're watching, are you!? :-)

Primed, sanded and primed again. I might get the color coats on tomorrow.

-

There's no use denying it. I love this design! It just gets more and more fun each time. I'm excited about the strat-esque one especially as well? Did I miss where you said what color it'll be?

Chris

It will be Sonic Blue - supposedly made from the exact Dupont recipe that Fender used once upon a time. Can't wait!

-

I have completed all routing and am in sanding hell... Will start finishing today I hope, weather permitting (since I will have to spray outside). The two wood finish bodies will be oiled, so I do them inside. Here are some pics of:

Recessing the bridges to create radius:

Pickup cavities:

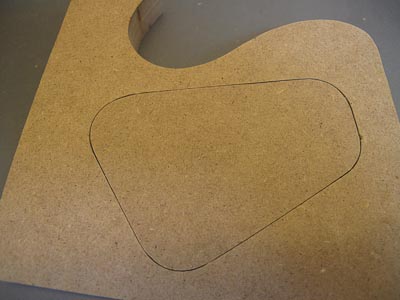

Control cavity recess and cover templates:

Cavity:

Covers:

And finished product:

How do you guys do control cavity recesses and covers? This is a labor intensive process for little added value if you ask me. Many hand-built guitars have wooden covers mounted with magnets, which is a nice touch and would add value, but I'm a little short on time for these particular builds.

-

Based on the slightly squared pickup-route shapes in the pickguard, will you be using the single coil alumitones? I've been dying to hear those on a handcrafted guitar.

Yes, they will be the "single coil" Alumitones - I have stripped the entire pickguard from my "Castaway Strat Conversion" that I did a while back. I have a few recordings of it (the Strat) with the same tremolo and neck, so it will be interesting to compare when I'm done with this guitar.

I will definitely put sound samples up as soon as it's complete!

-

Cheers guys. I am interested in the weight reduction factor, but am more wanting to test out the ideas that CF can help remove "dead spots" along the neck and improving transmission through the neck. I may spring for solid 6mm rod, or maybe even two 1.5mm thick battens. I could actually drop four battens all the way down the neck through to the bridge area since they're pretty tall. Any opinions on whether this will make any real difference?

I'm buying some West Systems epoxy soon as I have a few jobs for it.

Ah, I was jumping to conclusions regarding CF use. I wonder what gives the best effect in terms of sound transmission: hollow or solid? I might intuitively go for solid rods. My current experiments involve moulding my own CF rods as laminates in between wood of the neck itself. (Did that explanation make sense? Read my other threads here for details...)

Cheers,

Ola

-

Prostheta,

my EGS guitar has a 15 mm OD tube with a 2 mm wall thickness, which adds some strength to the neck and has allowed me to create a custom light-weight adjustable truss rod, but it is still not enough for the neck not to flex.

So, bottom line is: I don't believe that 4x3 mm will do much for you. I would consider maybe using two of the 6,3 x 13 rectangular tubes standing on edge to give some stiffness and remove weight at the same time. Definitely epoxi them in with really high quality epoxi designed to become hard and stiff like glass (not general purpose epoxi which is really soft and flexible)

Cheers,

Ola

-

Actually, the way it ended up was the 4 mm rounding - but this was the smaller one in the pictures! The larger was 6,3mm. Anyway, it looks very nice.

I'm actually most excited about the stratty one with the tremolo - it will be a fun one.

Next, I will route control cavities and pickup holes on the hollow-bodies and the tremolo cavities on the solid-body.

-

I was getting worried that everyone seemed to want the larger radius, since I was leaning towards the smaller :-) So, I'm glad we're getting a little debate here. Anyway, the larger radius doesn't actually touch the back. I think what I will do is try the smaller and see how it feels. I can always go for the larger afterwards (but not the other way...)

Buter: I'm around, so let's definitely hook up! Give me a shout when you know your schedule.

-

A short report on the router bit issue: the one that I bought (from gitarrdelar.se) isn't great. I noticed the hard way that the bearing is not secured properly, so suddenly it had slid down and the bit dug straight into my workpiece... I then fastened it better with a screw-on stop, which also came loose once. The way to go is to use a piece of teflon tubing like on the StewMac bits.

Anyway, two of the bodies are good to go:

I am planning on rounding the edge on the wenge top rather than using binding. What do you think for radius?

Top one is 2 mm and bottom is 4 mm.

8-string Fanned Fret Headless

in In Progress and Finished Work

Posted

Mattia,

read all about the CF in http://guitarworks.thestrandbergs.com/2010...r-construction/

It is a beast to work with machines.... I went through two brand new band saw blades just to make the first cut to separate the two pieces. I have then used a belt sander with 40 grit paper to do the rest of the shaping so far.

The only other experience I have to date is with the bolt-on neck I did before that has only two strips of CF. I shaped that with a rasp and then sanded down - didn't reflect that that was too bad though.

Our Souls: I can see that it would be tricky... Impressive piece of work you've got there. I would only do the cavities for weight/sound purposes in both sides of the body but then use a regular accessible control cavity with cover on the back.