-

Posts

75 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by godzilla

-

-

I had one I dyed green, and the dye job looked terrible, to get it off I used the stuff used for shocking a swimming pool, it worked great and it was less than 5 bucks for a gallon. It took it all off, after three applications. You gotta rinse it real well too.

Steve

-

I get my copper at basiccopper.com look in the bargain bin. Their prices seemed pretty reasonable last time I bought some.

Steve

-

I've used the foam pipe insulation.....I've put it over a screw driver handle and chucked it in a hand drill and the drill press. You can get it in various sizes and cut it into different shapes as well. There are different types out there with different densities. I also use PVC pipe with sandpaper wrapped around it.

Steve

-

Thanks for the quick reply. I have never tried to turn a hook without polishing and filing first, I'll give that a go. Thanks for that heads up.

Steve

-

When my Daddy died I acquired his scraper set. It is a Two Cherries set, rectangular, curved and gooseneck. I did some research, polished them up, got a burnishing tool and can turn a real nice hook on them. they have turned out to be a real go to tool for me. I am wondering what the life of the edge is for other PG'ers,I realize it is dependent on the amount of use, but they seem to dull quickly. I have been using them on hard wood, mostly maple, walnut and cherry. I'm just womdering what others milage might be and is there another brand that might be better. Thanks for any information.

Steve

-

+1 on leave it and nice going on the repair.

Steve

-

If your shop is below freezing, any humidity is obviously frozen. When you turn on the heat on it thaws out. I've seen this on my job in new construction a lot when the season changes from winter to spring....concrete especially. I would suggest to keep it above freezing and get a little ventilation going.

Steve

-

Thanks for the info, I'll just get the TB. Its for that tortoise shell/tiger eye finish that was done here a while back, and I want to get it right.

Thanks again.

Steve

+1 on Bill Shatner

-

Does anyone know which one it is, I'm thinking it is dark walnut. The TT dark mission brown looks closer to SM

medium brown

Thanks for any help with this.

Steve

-

The one above looks like an old recycled office chair.

Steve

-

Thanks for the help guys. Just have to motivate myself to finish sanding. Have gotten into tube amp building lately and can't seem to get focused on the final sanding on this guitar.

Thanks again

michael

Take your time when you do, you'll be glad you did. No one crows about all the time it takes to get that finish to "look like that"

I've done three that turned out ok finish wise, and people think their just the nuts, "how did you do that?".....I know they are not my best yet, but its a great boost to my ego.

Just trying to encourage you, michael!

Steve

-

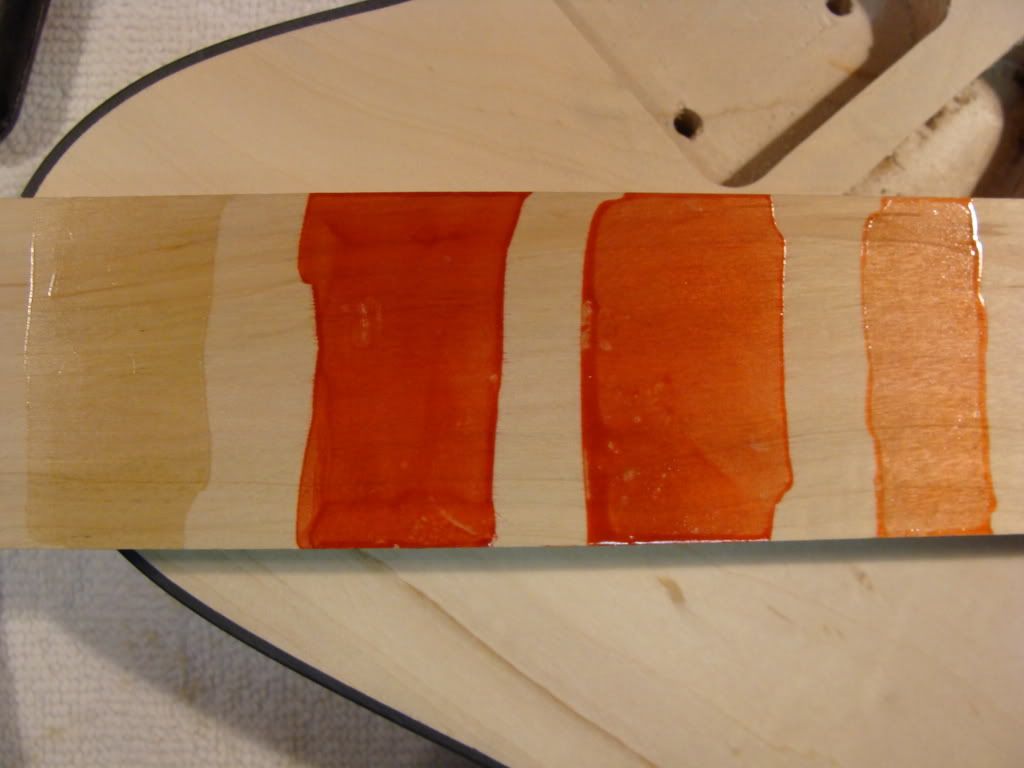

This is the eye dropper and ink I used

These are sanded back with 400 to take the shine off some

Edit: the red looks pretty orange on my 'puter...not so much with my eye on it.

I hope this helps some folks around here, you all have been very helpful to me since I've been here and I am very grateful.

Steve

-

I did some tests with TransTint on soft maple. This is going to go way over on the picture limit rule, so if a mod wants to move it..........

There always seem to be a lot of 'how can I get this color, or this look, or this finish' questions, so I I did some tests for anther tele-like guitar I'm building. The truth is a Primo Finish is achieved through many steps, and no shortcuts. When you do get those results it's a huge booster to your skillset. You just can't cut corners of the finish.

This is done on soft maple sanded to 400, it's not a 'perfect' finish by any means, but I think you will find it representative of what you can/will achieve

For this test I used one tablespoon of Zinsser Bullseye Universal Seal Coat, Product #00854. TransTint 6022 Blue, 6021 Bright Red, StuMac 5041 Green, SpeedBall black India Ink.

The photos show results of a clear coat of shellac, then adding 3 drops, 10 drops, 15 drops from the eye dropper shown.

You should be able to see which way the wood was oriented by the concentration of the color.

This one is the SpeedBall ink full strength then sanded back with 400,on the right is the BullsEye

This one is to show the grain orientation in the previous photos

If you look closely at the above photo you should see the grain running from the lower left to the upper right, rift sawn I think it is called.

This what was left over all mixed together.

-

-

does anybody here know a source to buy red (bright red, not tortise shell) abs plastic binding? i did find some red and green dyed maple ones on stewmac or lmii, but i'm trying to find something really bright.

also, i've been looking for plastic sheets to cut inlays from, and the only things i find are 1/8" or thicker. does anybody know where to find some thinner pieces.

i'm basically going for the same look as those ibanez rg 770 dx 1987 re-issues, but with binding to match.

on a different note, is there any way to get mother of pearl blanks in colors. the only things i've seen are the pearl color, gold, and i think i remember seeing some dark gray ones.

all suggestions are greatly appreciated. maybe you know a place to find some other colors of these materials; that would be appreciated also.

You've Got mail.

Steve

-

-

Looking good...I'm not sure about the fretboard height issue, I'm sure someone will chime in on it.

Welcome to the forum.

Steve

-

What Mitch said.......once you get the bridge on you could clamp the neck on and put some fishing line on it to check the alignment.

Sounds like a fun project for you guys. Have fun with it.

Steve

-

I think that the warm cars being parked on the other side of the wall, and the dripping snow off of those cars is causing humidity in my shop to rise up and collect on the ceiling where it freezes because that side wall is not protected from the wind outside and is by far the coldest wall.

Sound possible ?

The RH in my shop right now in the dead of winter here in Iowa is 65% to 67% according to my gauge.

Quite possible that is a contributing factor. Is the attic portion insulated? Is your shop area tightly isolated from the rest of the garage, you said it is walled off and those are insulated...are the outside walls as well? The best thing to do is to add heat, if you can and ventilate.

I keep my shop at 50-55 F unless I'm out there working (it's a garage as well). I have R-19 in the ceiling and R-13 in the outside walls.

At my house the cars stay outside, so the overhead never opens.

My guess is you need to add heat and vent the moisture out as you surmised, the problem there is you are sucking the heat out as well.

Maybe someone will have another suggestion. Good luck.

Steve

Yes, the attic portion is insulated. The main garage walls are all insulated and the two overhead doors. The wall that I put up between the two main stalls and the third stall (my shop) is NOT insulated. Just drywall on the garage side and open studs on my shop side. I wouldn't say that the shop is tightly isolated from the garage.

I would say if you can tighten up your shop and add some more heat that should make a big difference. You have to be careful, if it is that humid you have the possibility of mold and/or mildew forming and you don't need that.

Steve

-

Well i have wet sanded with 400 and absolutely cannot get the shiny spots gone. The grain gets smooth first and in between doesn't seem to get touched by the paper.

Careful with that 400 Eugene.

I sanded through with that stuff....I would use 3M 600 with mineral spirits till you got them out then another 5 or 8 coats let it set for a month to 6 weeks then start with the 600 again.

I sanded through with that stuff....I would use 3M 600 with mineral spirits till you got them out then another 5 or 8 coats let it set for a month to 6 weeks then start with the 600 again.Good luck.

Steve

-

I think that the warm cars being parked on the other side of the wall, and the dripping snow off of those cars is causing humidity in my shop to rise up and collect on the ceiling where it freezes because that side wall is not protected from the wind outside and is by far the coldest wall.

Sound possible ?

The RH in my shop right now in the dead of winter here in Iowa is 65% to 67% according to my gauge.

Quite possible that is a contributing factor. Is the attic portion insulated? Is your shop area tightly isolated from the rest of the garage, you said it is walled off and those are insulated...are the outside walls as well? The best thing to do is to add heat, if you can and ventilate.

I keep my shop at 50-55 F unless I'm out there working (it's a garage as well). I have R-19 in the ceiling and R-13 in the outside walls.

At my house the cars stay outside, so the overhead never opens.

My guess is you need to add heat and vent the moisture out as you surmised, the problem there is you are sucking the heat out as well.

Maybe someone will have another suggestion. Good luck.

Steve

-

So what im going to do is just wet sand with 600 and up and then buff- that sound about right?

How many coats are on it?

Steve

-

"They have a Milwaukee 2 1/4 HP for $124 with two bases."

Hey Godzilla,

What model was that? I can't find it on their site. I see one matching the description, but it's more than that and they say the coupon code doesn't apply to that one.

Thanks!

Gavin

They may have sold out of them.....that link is not displaying the same page now.

I'm not sure what model it was.

Steve

-

Getting A Good Blue On Maple

in Inlays and Finishing Chat

Posted

I am sorry for any confusion I may have caused, that surely was not the intent.

Steve