-

Posts

331 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by supplebanana

-

-

Seems like it's doing it's job - but I'd be vacuuming it out rather than blowing it out - kinda defeats the object otherwise.

-

See - I told you, I told you! Don't mock The Curse!

-

Just remember like I said in DemonX's thread - sacrifice a goat first!

-

Not sure what you mean - I've never worked with it.

Cursed wood is kind of a running joke around here and gets used when a particular piece puts a up a greater fight than normal......meaning it don't want to do what you want it to. It started with RAD's Hand of Doom. He fought the ziricote constantly on that and had to re-do several steps on that build. He claimed the thing was cursed. After that several of us have claimed cursed wood when we have a piece that gives us trouble. My current build is zircote and I've had a couple of mishaps that will require re-doing steps as well.

Not the wood's fault at all-it works fine or as well as any very hard heavy wood does, but it makes me feel better to blame it on the curse.

SR

Don't mock The Curse, man! I used to have car that was Cursed - so much so my wife called it Christine. I'm sure it must have had some ziricote in it somewhere.

Ziricote grows where the Aztec & Mayans used to live so maybe it's some ancient curse (like the Curse of the Black Pearl!) or something - kinda like Montezuma's Revenge. I've only ever had one piece of wood fall off my shelf & hit me - a ziricote fretboard! I have 2 waiting to use - not sure about using them. Maybe if I sacrifice a goat or something 1st.

Anyway - I look forward to seeing that acoustic.

-

Looks like it came out pretty awesome... for a strat

Must be pretty dang heavy if its northern ash.

Thx killemall - yeah, she's pretty solid . Don't mind heavy guitar's - played my fair share of LP's over the years but these days most of my playing's done sitting down so I don't notice as much lol! I also get it that a lot of people don't like strats - I went thru a phase when I wouldn't have touched one with a barge-pole & ironically it was when everyone else was playing pointy 80's hair & thrash metal guitars that I started playing strats - I think I just wanted to be different lol. I had a strat copy that was one of the best guitars, after I sorted out it's woe's, that I've ever had the fortune to own. I payed next to nothing for it, fixed it up, used it as my main guitar for about 5 years & then sold it for 8 times what I'd payed for it. Within 2 weeks I'd realised I'd made a mistake & tried to buy it back but the guy wouldn't part with it.

So I vowed to build myself another better one - it just took me a while to get round to it.

So I vowed to build myself another better one - it just took me a while to get round to it.When I get chance I'll see if I can find my luggage or fishing scales & weigh it.

She's a beaut all right!

SR

Thx also Scott.

I really appreciate these comments - both coming from builders who have already earned my respect as fantastic builders many times over.

-

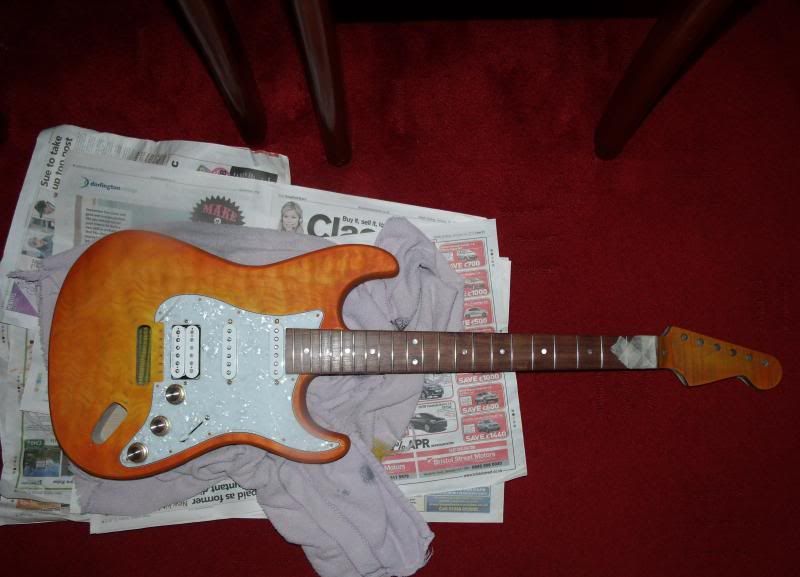

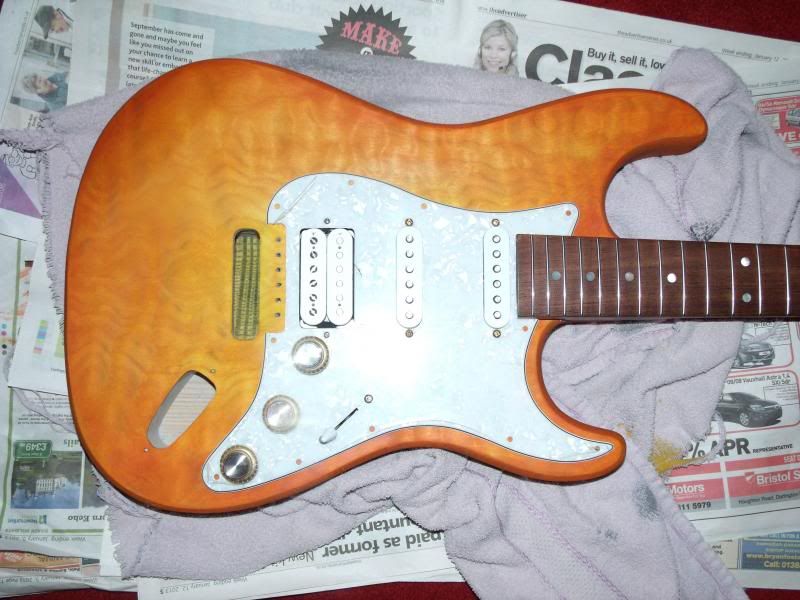

And she's done!!

What have I learnt from this build? - patience pays off. It actually plays better & sounds better than any of the other guitars I have built or bought & they include PRS, Ibanez & Fender.

I took it into work yesterday as some of the playing & non-playing folks wanted to see it. One of the guitar playing guys said that it played & sounded better than his Fender Strat & my boss was speechless (which is unusual!)

I've just looked at the date I started this build thread - Jan 25th 2010! It's a whole year longer than I thought it was, where does the time go?

Anyway - I digress - final specs are....

Wood

Body - Northern Ash with Quilted Maple veneer.

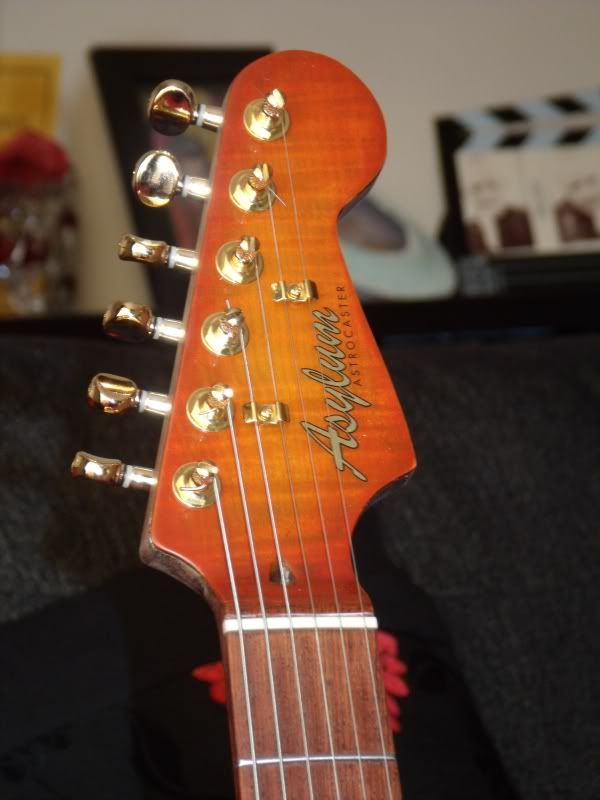

Neck - Indian Rosewood with Honduran Rosewood fretboard, 25.5" scale, 22 stainless steel vintage frets. MOP dot markers. Flamed Maple veneer on h/s face.

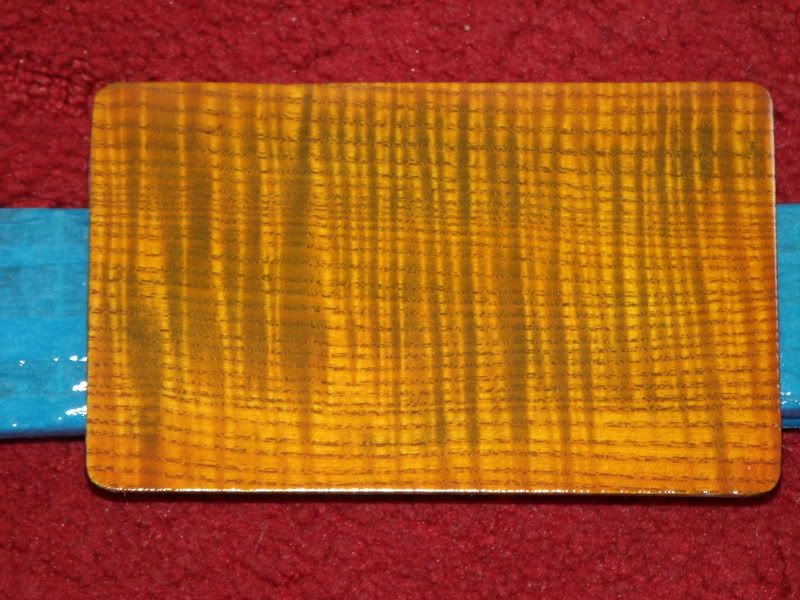

Backplate - Flamed Ash

Pickups - Seymour Duncan Custom HB at the bridge & 2 Fender Single coils in the neck & middle postions (middle reverse wound)

Hardware - All gold plated. Synchronised vintage vibrato bridge, locking tuners, Marvel locking strap buttons, pearl white scratchplate. Graphteq nut.

Controls - 1 Volume, 2 Tone. 1 Tone for the neck single coil & 1 for the bridge HB with coil tap on neck tone for HB, 5 way p/up selector switch.

-

Headstock decal & backplate.

-

Right - time for an update.

Spraying the 1st dust coats...

-

Be careful... you're saying that you love RAD's wood..... not necessarily a bad thing... if that's what floats your boat...

-

Oh no! Not another "Hand Of Doom"!!!!!!

Stay strong!

-

I'm glad you said that that was oil in that cup!

-

Moy, you in the UK? If so I'm only about 30 miles south of you. Don't bother with DIY shops - you want Car Paint dealers or if you're pushed try Halfords.

-

Ken Lawrence? Who's Ken Lawrence? He can keep his headstock!

Fox? looks more like a mean bad Wolf to me...

-

i've heard of this... but never tried it....

-

Acrylic is the same thing as waterbased lacquer. You should be able to use whatever you used for that before.

Thx fpr that - I tried some of the shellac that I normally use on some scrap & then when it was dry I brushed on some KTM - fingers crossed - so far it's still good, but I'll give it a couple of more days to be sure

I use KTM-9 exclusively and have never had any problem with ash. However I don't get it really, you have already dyed the wood and now you wnat to grain fill? I would have grain filled before dye. As it sits right now my only advise is to go heavy on the KTM-9 on the back so that you can very carefully sand everything flat. Brace yourself for something like 15-20 coats to get the pores filled. The only alternative I se apart from that is to use clear grain filler if you can get that. Crystalac had some that I sill have half a bucket of that work fine with KTM-9. but apart from that I haven't really seen anything like that.

Because not all grain fillers can be stained/dyed & when they can they sometimes end up blotchy. That crystalac looks good but I can't find a local supplier. 15-20 coats is no problem, I'm happy to do however many necessary.

Where did you get those magnets from? And what are the dimensions?

They are just some I've had around the house for years, I'm not even sure where I got them from now,

-

So.... I need some advice.... I'm about to start finishing this & I plan on using waterborne KTM-9.

This is my 1st time using KTM-9 as I normally use nitro or Acrylic.

Any advice on how to deal with the Ash would be appreciated. Anyone recommend anything easily available in the UK that I can use to grain fill the ash that won't react with the KTM-9?

-

-

-

-

-

Dying figured maple is sooooo much fun!

SR

It is when you remember to put gloves on! lol.

Luckily it's water-based.....

Anyway time for a long awaited update.

Been sneaking in the odd few minutes/half hour here an' there and this is where we're up to now.

this is the jig I made to route the recess for the cover plate.

Recess cut.

Test fit.

-

Let the haters hate...lol, I like it - I was just trying to show a possible influence. And I love the Pro-line too

-

Like this you mean? Ibanez Proline mid 80's

-

I used to have a strat that I re-sprayed with that colour orange - when I came back outside to spray another coat the sun had come out & it was like getting a welding flash! I had afterburn on my retina!

looking cool all the same!

-

1

1

-

Kea's Guitar Build Thread

in In Progress and Finished Work

Posted

looks fine to me - mighty fine actually