-

Posts

216 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Buter

-

-

Welcome!

Im from Port A, Scott R is a Hustonian and Wes is up in Austin if I recall correctly.

Buter

-

Most of this thread was lost due to an IPA related incident

but this looks like what you are after.

but this looks like what you are after.

Scott will be happy to answer any questions as soon as he sees this.

Cheers

Buter

-

Looking forward to this, sir!

-

I had actually searched his PG history and couldn't find it. I then went to his website which only showed dead links (while at the pub), so I'd assumed he was done. Having just clicked on his site from the hotel, I'm actually quite pleased to see that his site is still alive.

You're a great builder, sir, and I look forward to your next builds, should you chose to build again.

Cheers

Buter

-

As somebody clawing his way back from a 5 year absence, I can totally understand.

Im assuming many of us end up believing that we can do this as a living, only to be knocked back by the realities of it all. In my case, my workshop was just too small to work on anything but a single guitar at a time. This led to mistakes and frustration that I couldn't quite deal with anymore (at one point I smashed a neck through that had around £600 worth of wood in it (flamed maple and ebony stringers with a quilted top).

This was the same time I moved onto the Jumbo. After much deliberation, and draining of rum bottles, I elected to return to work full time and abandon the workshop. I chose radio silence at that point (apologies for not responding to your email;not my finest hour).

Anyhoo, 5 years on, a proper workshop, different outlook on life and a great project in the pipeline... Let's get 'er done!

B

-

1

1

-

-

Grassy ass, ameego!

Just tried to PM you and it just kept shutting my iPad down! :0

I ended up just asking on the RAD thread (would love to see him here again).

B

-

Anybody have a link to the thread about RAD's build from about six years ago - neck through with a top plate on it? I remember that he and I had very similar build styles.

Cheers

B

-

So I'm sitting in a pub, 3,500 miles from my shop and the guitar within, and I'm trying to think through each step needed to complete the little beastie. I'm shocked at how many times I've needed to go back and add or re-order things. I appreciate that a neck through with a top is probably the most difficult electric we build, but I'd love to see/know if any of y'all have a fairly regimented build process port your builds. I've seen Loius's, which is great for a basic set neck (I'm only saying basic as it only includes the big steps, not that his guitars are basic - they're awesome!).

Ive already managed to make things difficult for myself on my first comeback guitar, and I'd like to keep that from happening in the future. I think it would be great if everyone put some thought into this and came up with some fairly definitive workflows and the reasons behind them. There will obviously be different trains of thought on why some steps come before others and there will be different flow patterns based on the many acceptable ways there are to build guitars (just read a very good post last night by a chap who frets the board and shapes the neck as different pieces, then marries them up with minimal clamping).

When I figure out my flow, I'll be sure to post it up as well, more for correction than instruction!

Cheers

Buter

-

Yeah, bring me a few, dude. I'll take you fishing while you're here.

Cheers

Buter

-

1

1

-

-

I ordered a few Hotrods with my last order. Archaeologists will uncover them, still in my workshop, in a few thousand years. I'll not be taking that much meat out of my necks.

-

Well, I said I was done, but my morning chores were finished earlier than I'd thought, so after going for a swim I thought I'd knock the next couple of items off the list. I almost wish I hadn't, because in my eagerness to get a few more jobs done, I've made life harder on down the road.

I had planned on building a clamping/gluing jig to attach the headstock ears, but I just clamped the headstock pieces to my slate and clamped 'em up. The result should be fine, I just wished I been patient.

I had also wanted to cut the wiring channels in the centre section while the neck blank was still square. Oops. Who wants an easy life, anyway?

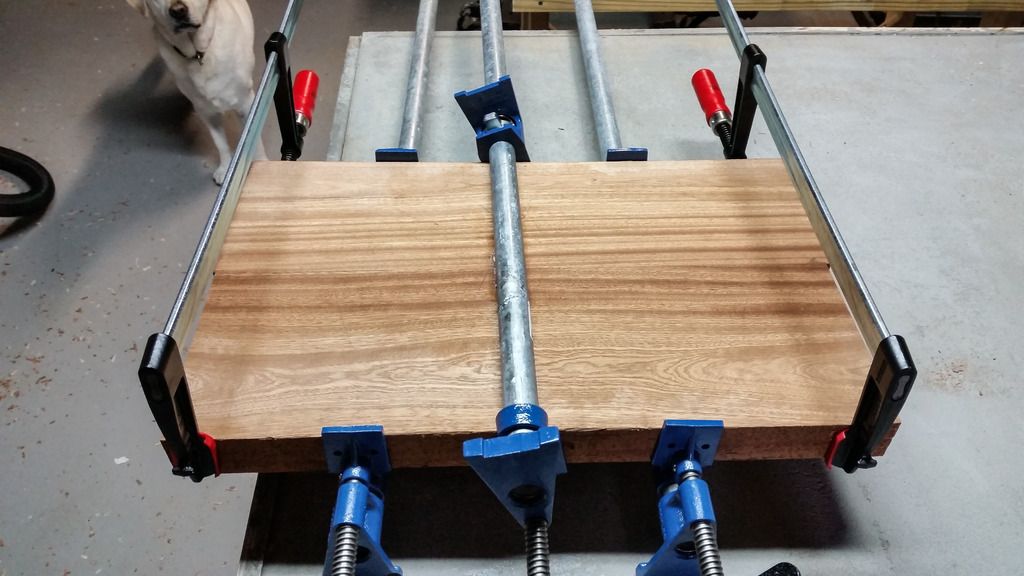

I'm already thinking about the next project so I thought I'd glue up a body blank. Does anyone ever get tired of putting two freshly planed chunks of wood together and trying your darnedest to find a bit of light poking through, even though you know you won't?

So that really is all for now since I'm writing this from London.

Happy holidays everyone!

Buter

-

Yup. My Aunt and Uncle live there and we go there for Christmas (via Hong Kong this year...).

As feared, not as productive today as I'd hoped. My first project this morning was to build a scarfing sled for the router. I thought before I did, I'd just see if I could put the glued up headstock back in the jig for the table saw and get a respectable result. Turns out I could!

Made up a jig for gluing the headstock to the neck and clamped her up.

Yeah, I'll call that a win (had to include a foot shot for y'all).

While the glue was drying I made the fretboard template cut her to size. Normally I'd cut the board 3mm skinny, cut the fret slots, then glue the sides back on to create a grain matched binding type thing. I did that with this but the off cut started twisting up, so I abandoned that idea and won't bind the board on this one. I'm just playing, after all.

By the way, the router bit with bearings top and bottom is one of the most useful tools I've got; very easy to make sure you are always routing "downhill". Go one way with the template on the bottom, flip the piece and template over, lower the bit to run the top bearing on the template and you're routing downhill again.

i don't have the router table fully built yet, so I clamped the neck off cut to the table as a fence.

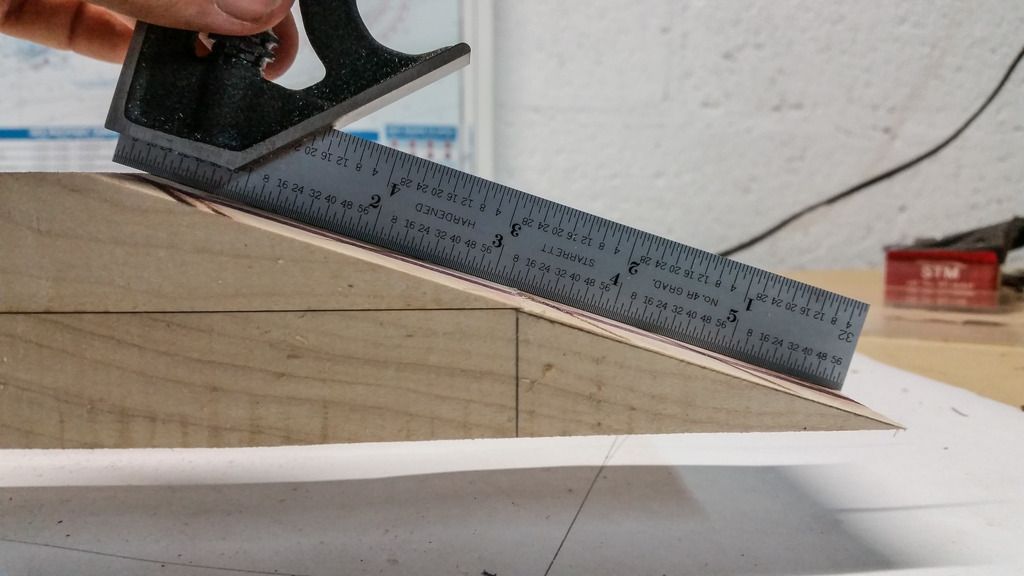

Run a test piece to make sure I've got the fence set just right; wouldn't want to make a dumbass mistake here, would you?

Perfect!

A couple of passes along the fence and I've got a snug little channel for the truss rod, slightly offset to the treble side. Why offset, you ask? I'm running a fairly thin neck and wanted to put a carbon fibre rud in the neck for stability, so I offset the truss rod to the treble side and put the carbon fibre rod on the bass side.

Well, that's it for a while. Work, Christmas and life are getting in the way for the next month. I'm slightly bummed because I was really getting into it and enjoying building again. Soon come...

Cheers

Buter

ps - you didn't really believe I intended to offset the truss rod, did you?

That little boo-boo really pissed me off since I am very careful and always make test passes. In this case, however, I didn't realise that I'd flipped the test block and was setting the fence to the wrong datum. I absolute nailed the wrong line, though, eh?

Fortunately, I had a few CF rods that I used to use for reinforcing bass necks. I will be interested to see what effect this arrangement has on neck stability.

-

Yeah, even as I was marking out the blank I hadn't decided if I was gonna go with a one piece or a scarf. The accent piece won out in the end.

What you see is a piece of slate from the pool table that was here when we moved in. I love playing pool, but there wasn't enough room to really play where it was. I contemplated setting it up under the house, but it didn't handle the move very well! Makes for a good, if not delicat, true surface to play with.

I've been adulting all morning instead of building, so I may not accomplish my goals today.

Why anyone ever wants to grow up is beyond me!

Do you live anywhere near Kingwood, Scott?

Cheers

Buter

-

8 minutes ago, Buter said:

-

I know there used to be limit on photos, but I believe that was due to server capacity and now we mostly use hosted pictures so no more picture limit. If I'm wrong, let me know and I'll break this up into multiple posts. Also, I'm on an iPad, so the chances of ther being no typos (unwanted commas seem to the favourite).

My goal today was to get something glued up and be cleaning up with a cold beer around 5. Sounds like an easy goal, but I've got to make new jigs for everything. Soooooooo..........

We need to make this big hunk of wood a bit more guitarish, so let's fire up the ancient bandsaw and make some sawdust.

2 pieces

Not too shabby for an old thing.

I had a big panel saw with a big sliding carriage when I was in the Channel Islands which made doing scarfs a breeze. Alas, the big saw is still in the Channel Islands and I am not. I guess I need to make a quick scarf jig. Some old, oak floorboards planed and cut to fit these slots.

Screw them into some 18 mil MDF.

True up some lumber and attach in an eye pleasing fashion; 17.5 degrees to the blade in this instance.

Clamp one neck blank in place and make sawdust.

I'm a firm believer that the majority of time spent on any project should be spent in the thinking phase. The thinking phase is used to figure out what to do in the setup phase. Time spent in the setup phase is usually much more valuable than time spent in the doing it phase. Time spent in the doing it phase should be kept to a minimum. In this case, proper distribution of time in the three phases led to a scarf joint that I could have roughed up a bit with some sandpaper and glued straight away.

Sadly, I will not be gluing this up immediately as I want to add an accent piece to the neck/volume. I think sending my little headstock piece through the planer would end in tears, so I knocked up a quick little thicknessing jig.

Mission accomplished! Quarter to five, headstock and accent piece in clamps, cold Sweetwater 420 on the go, broom in hand and Hank Williams III on the tune machine.

One more full day in the shop and then I'm all closed up until January.

Cheers

Buter

-

Ha! Didn't see the duck or the horns. I guess we'll call her El Toro (was gonna change the topic to that, but can't see how).

I'm a full on hop-head now. I'd rather drink tea than "traditional American" beers.

I'm not sure how you noticed that I was gonna do more than your average headstock angle, but you've nailed it, Scotty! In my experience, you need a greater angle with zero fret guitars.

Thanks Salamon; I hope I won't disappoint you.

Cheers

Buter

-

Well, it's been well over 5 years since I've built a geetar, but I've got a great project in the works, so I need to get back up to speed.

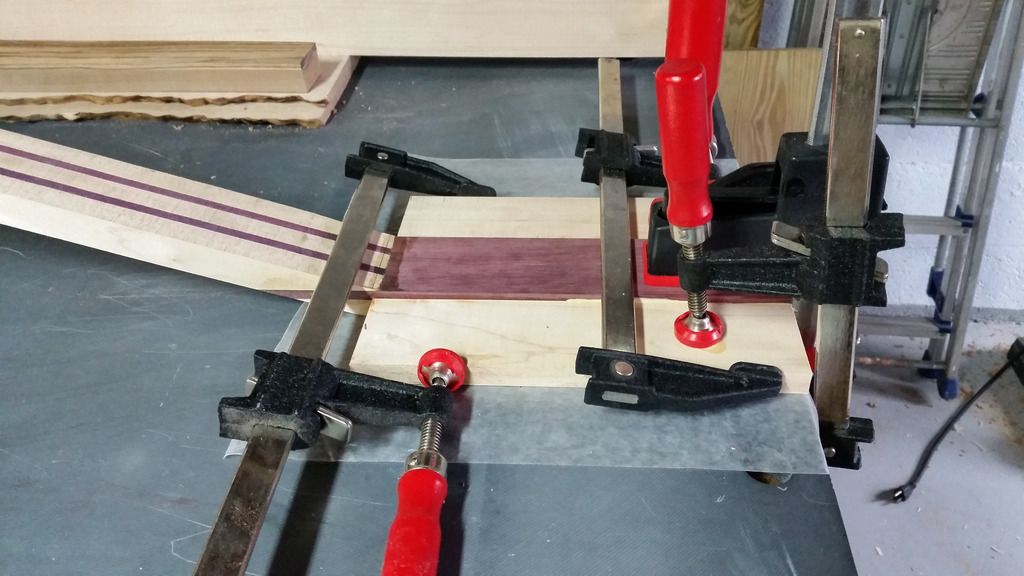

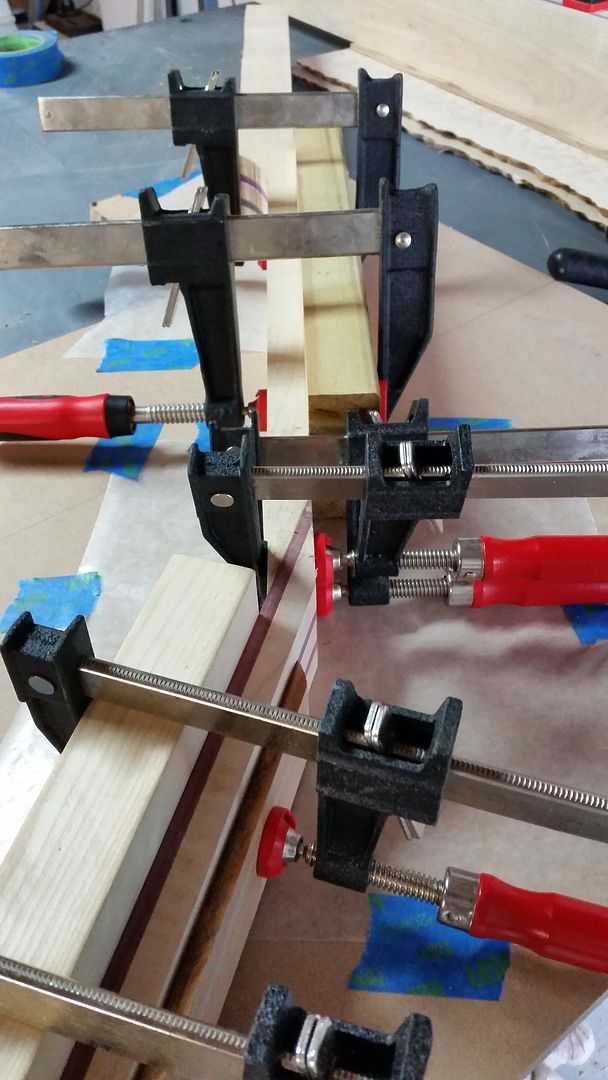

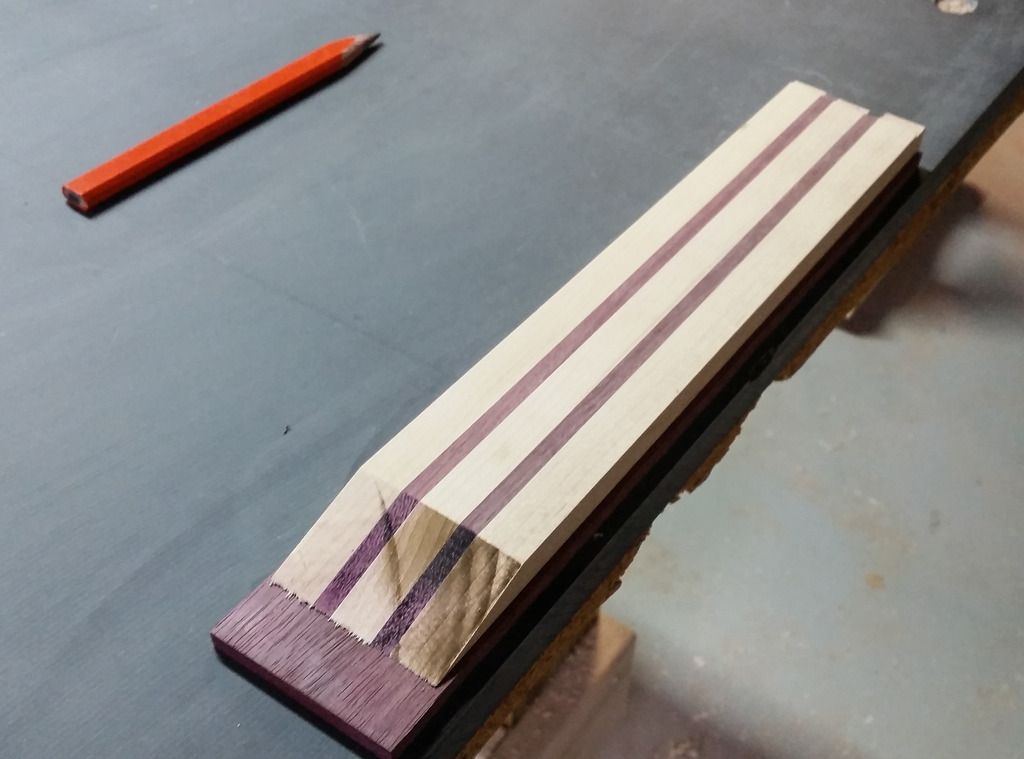

Mostly parts left over that actually made the move from Europe back to 'Murica, but the gist of it is Maple/Purpleheart neck-through, quilt top, Sapelle wings, Zebrawood FB, JB/59 combo, Grover and Schaeller shiny bits.

Wish me luck!

Sun's going down and this is the view out of my shop, so I'm gonna grab a cold IPA and chill on the dock.

Cheers

Buter

-

Would have been my first guess, but his videos show him building it the old fashioned way.

B

-

1

1

-

-

I'm stuck a few thousand miles from home and it's driving me nuts. I'm dying to get back to building again after a 5 year absence, but I've got a couple more months before I can get back into the shop.

Im using the time to order materials and tools, as well as scour the Internet for ideas, inspiration and good, old fashioned knowledge. I've just been on to the telecaster sight and seen the following link. I think the best bit of advice I will be able to give anyone interested in getting into this hobby of ours (for more than one of two instruments) is to invest the time to build something similar.

You probably won't need all the functionality that this guy built into his machine, but there's some very sound principles that can easily be adapted to your needs.

Many thanks to the gentleman who took the time to post.

Enjoy!

http://www.instructables.com/id/3D-Router-When-a-CNC-machine-is-overkill/?ALLSTEPS

-

Sounds reasonable in theory, but I personally wouldn't try to get within 1 mil of a cut line with a jigsaw; they can be ornery little critters!

What other tools do you have at your disposal?

-

Yeah, you kinda just typed out what was in my head.

With high end parts like these, you'd have way too much money sat on the shelves waiting for the one guy who wanted/needed them. Just for one instrument I plopped down $350. Assuming they sell to distributors for half retail and just trying to stock the hardware I bought in the 4 colours it is available in will leave you with $700 sat on your shelves.

The only viable business plan would be to have regional exclusivity, but, on top of the money it would take to be adequately stocked, if the manufacturer starts getting complaints that you can't supply basic parts without ordering them, they will start looking for other retailers/distributors.

Doesn't really sound like a game I want to play.

-

So there appears to be no distributor, as such, but All Parts was willing to order the parts on my behalf since they stock Schaller, but the timeframe was was 1-3 months. I replied that I could work with 4-6 weeks, but after 3 months I'd probably forget what the parts were for when they arrived.

In the end, it was much easier to order direct from Germany. 10 day delivery cost €10.

-

Hi Pros...

Yeah, they carry some parts, as do a few others, but, as far as I can tell, no one carries a full range and the U.S. is absent from their list of distributors.

All I was looking to do was get a bridge and some machine heads in the brushed copper. Try finding it in the states.

Why have Allparts, Stewmac, LMI, et al... not picked up the distribution rights? Am I missing something?

-

Gentlemen, am I crazy, or is there no Schaller distributor in the U.S.? I've only just moved back from Europe (where it wasn't an issue) and I can only find a few odds and ends.

I was on their website today as I need parts, and I'm finding it difficult to order anything. Question for you lads - is there a U.S. distributor, and if there isn't, is there any merit in establishing one? Is there enough demand in the U.S. to meet the distributor requirements?

Your opinions would be greatly appreciated.

Cheers

Buter

Another Les Tele Thing.......Heheheh-Mine!

in In Progress and Finished Work

Posted

Well, I've found my hero for the day.

Sixer of Jai Alai headed your way, sir!

Cheers

Buter