-

Posts

124 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by XBIGJIMX

-

-

Would you like this frontpaged?

That would be great

-

So anyway I have this Craftsman Drill press I was given, but I already had a floor drill press. So i posted it on Craigs list but after a month no takers what to do with it. Well I was half asleep and the thought popped in my head .."Hey why not make it the buffing station you need". So I said well that a damn fine idea.....

So the only thing I bought was the wheels and this from Grizzly

After pulling it apart and tossing the extra parts I was left with the motor , pulleys, belt, and stand.

So i started off adding some extensions so I would have some clearance from the stand so I don't accidentally bump into what ever i was buffing. So I grabbed some scrap Cherry and Maple. I cut em to the size needed and angled the edges with a hand plane.

Now I was really interested int he pulleys because I wanted the ability to adjust speed. Cause when doing finishing slow is always good. Now the first issue was the I.D. was to small to fit the arbor. So I am to cheap to buy the correct size so lets mod this sucker out. To the Lathe! So I bored it out to fit and then drilled out and tapped 3 set screws in the first hub.

Next Plugged the countersunk screws with Walnut and added a few coats of Tung Oil. And made a box for the switch out of maple and wired that.

Now with everything bolted in. I added the wheels and made some washers/stiffeners out of some end grain cutting board scraps. And boom one professional buffing machine with adjustable speeds

-

-

-

Normally it's $50 a pallet. But at auction it starts at $5.

The guy told me they sometimes get 1 a week dropped of and sometimes the dump off 20!!

-

Well I had some time to kill at my local auction house the other day and $100 burning a hole in my pocket, so I did when any red blooded human would do I spent it on wood of course but I think I got a bargain. So 4 truck loads and 7 pallets later and $85 spent here is the haul(s). So far I have found Maple, Curley Maple, Walnut, Mahogany, Cherry, Brazilian Cherry, Poplar, Oak, and Beech.

Funny part is my 17 year old son needed $10 to go eat and asked for some money and I told him I had some woodI need taken down to the shop wanna trade?. He looks at me like he is the master negotiator and goes $15. I am like sold. He sooooo did not look in the garage first before quoting a price, I think he is planning my death now....

Load #1&2

Load 2

The masses

-

The headstock binding is a real nice touch

-

This may solve your problem since your looking for an easier press. Change the handle to to 24"-36" I am not sure the size of the grizzly handle rod , but the end caps should come off to remove it. Go to your local Home depot or metal shop and get a cold rolled steel rod the correct length and swap them. Its the same concept as the mortiser machines (ex http://www.amazon.com/gp/product/B000BX1JQU/ref=s9_hps_bw_g60_i1?pf_rd_m=ATVPDKIKX0DER&pf_rd_s=center-5&pf_rd_r=1EK2B64MSE1Z16E763PD&pf_rd_t=101&pf_rd_p=1315755002&pf_rd_i=228437)which are much harder to press then frets. This should change the fulcrum ration to ease the pressure to press.

-

Use Tyvek tape to seal up any cuts in the plastic. Also did you leave an air gap in between your foundation walls and framing? Moisture builds on the inside of the concrete and will rot away any dry wood that is touching the concrete in no time.

Yes I left an 1/8" gap (didnt really have a choice the wall and floor were not very square

-

+1 on that.

Also, you need more clamps. This goes without saying though.

Most def on this!

btw are parallel clamps worth the money or just over kill

Are you going to hang drywall in there? Exposed fiberglass insulation is not good to breath in. Plus not having a proper vapor barrier allows an excessive amount of moisture into the shop rusting tools and changing moisture content of wood.

Yes the moisture barrier is going back up I cut it down to run electric.

Dry wall will be done a few sheets a pay check so its not sticker shock over load

-

good lord, who would of thought sawing through stone would take a while ... but well worth it I got 2 good 4 x 6 slate table tops !

But with the pool table out, off to do the nasty...oh the part i was dreading moving the tools and small stuff from the garage to the basement. I was trying to think of the best way to do it and i finally settled on just shove everything in a tote and then just go through it when it was moved down there. Now the real crazy thing was how my kids suddenly went missing when it came time to move this stuff. It was like a teenage ghost town. What can you do.

First things first the imortant stuff, Everyshop needs the ability to watch football and hockey while working so we got the Surround sound tv hooked up with access to the DVR (thank you hoppa!) and apple TV.

And sometimes you need a break so lets move the lazy boy in as well. This actually serves a dual pourpose. This also gives my wife a place to chill and relax and do her thing while I am working. Solves the problem of "Your always hidding in your shop" well come hang out.

The tool boxes and parts boxes in so let the organization begin. Also got the Lathe in. It amazes me how heavy that dame thing is

Temporary chop saw hooked up along with a demon supervisor

Making use of the high celings as well as getting some storage. A few cables and boom storage out of the way!

And same soulution for the sheet goods . Fits a 4x8 plywood sheet and i can do chin ups on them so i guess they will hold.

A new look so far!

-

Moving over to the area of an assembly bench I have been wanting to do a tortion box or something with a dead flat surface like a sheet of stone...hmm where can i get a nice flat chunk of stone....wait isnt a pool table dead flat. Hold on dont i have a pool table I can't give away. hmmmmmmm lets take a look under that felt oh yeah!!!!

One giant plywood size 2 sheets of 1/4" of dead flat slate sandwiching a 2 " MDF'ish material. plus the rails are solid wood to repurpose.

Now just have to cut it down to some usable sizes

-

It's all about restraint. haha. But remember the murder starts when I pretty much traded cd's and guitar picks for it. westhemann you can come over you can use th eshop and i'll pick your brain.

-

Arrrrrrr - pin router. Always wanted one of those but never got there. Not too common around here and the price is high enough I decided to leave it and put the money into cnc one day

It's not a self contained unit ( i had to supply the router) but found it on craigslist for $200. I really want to get one of the stand alone units though the possibility seem endless

-

Well me and the kid made the treck through the snow to move some machines in. Good lord some of these were heavy and unruly as hell hahaha. But time to unpack the new stuff clean the used stuff and introduce some tools whoo hoooo

Lets crack some crates open!

Grizzly knows how to pack

Next up is my $300 Spiral grizzly jointer as you can see is used time to clean it up!

Who says you can't bring back a shine!

Oh the Craftsman $150 table saw looks like it wants a go as well. As you can see it's used which when i got it, it decided it was good day to rain on the way home

But a little elbow grease later...

Now lets do a little walk around

Jointer

New 17" band saw

My used $300 jet planer and new grizzly drum sander

12" Rockwell Disc sander and Shop Smith Pin Router

Drill Presses!

-

I have a rack over the chop saw for the lumber and if I need more I can use the other wall. I am thinking of building an over head rack to store sheet goods on the ceiling

-

I have been getting packages like its christmas. The best part this has cost me $0 out of pocket all this was payed for by stuff I had in my basement. I also used this to do all the work readying the shop.

THAT IS FLIPPIN' AWESOME! I'm gonna come and play in your basement.

The layout mostly looks good; I'd move the dog a couple of feet south and put the cat under the table.

SR

Come on by I can pick your brain!

Plus everyone know the dog will be under foot and the cat will want to lay on anything your trying to read or do

-

That's a nice basement. It sounds like you've got plenty of receptacles. Have you bought any tools yet?

oh yeah, I actually just went and bought tools.

In the past 2 weeks i got:

17" grizzly bandsaw

10" grizzly drum sander

grizzly downdraft table

Jet 12 planer

grizzly 6" jointer with spiral byrd cutter

Cast iron top craftsman table saw

Buffing station

12" sliding compound miter saw.

new maple workbench

stew mac fret cowl press set

fretting slot blade

Shop smith pin router

Stewmac perscision router base

Set of fret files

Rikon Air purifier

I have been getting packages like its christmas. The best part this has cost me $0 out of pocket all this was payed for by stuff I had in my basement. I also used this to do all the work readying the shop.

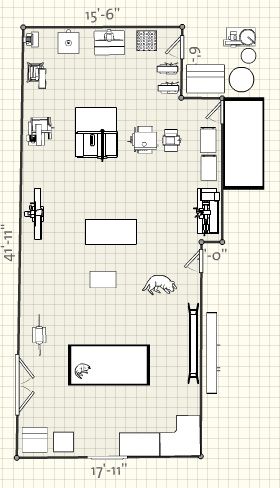

Here is a rough plan of the room

-

oh new tool day how i love thee...and the $34 lift gate service worth every damn penny

-

Spent the day pulling wire... i swear if i have to pull one more foot of romex! Got about half the shop wired and all the wire ran.

So far here is what we got

10 lights run on the celeing

8 - 220 outlets 30 amp with 10/2

15 - 110 outlets 20 amp 12/2

2- 110 outlets 20 amp in the celeing 12/2

The Compressor, Dust control are on there own breaker. The rest are spread out over the box.

Tomorrow the second part of the Grizzly order comes in.

-

hey I am glad some one is double checking my work especially the electrical... Stupid not burning the house down . I will say though wire is so damn expensive

-

You sure you're using the right gauge cable on 20A MCBs? That wire looks awfully skinny for power circuits.

I have to go down and double check I am using 12-3 .

The 100 amp main lead line was single 6 it may have been 8 all i know is it was almost impossible to cut with wire cutters

I am guessing the wire in the pic is correct cause that was what already ran when i moved in i just moved it from the other box.

-

thanks, it is roughly 16x40 not including the spray booth area defiantly got some elbow room

-

Hey everyone, well i have been wanting to do this for ages...build "the shop" nd if i post about it i will not procrastinate working on it hahahah

I have done everything in the garage for th elongest time but it has gotten to the point where i want to actually park in there. Plus after my Thyroid was removed (it acts as the bodies thermostat) it is always to hot or too cold in there to work. So I took over a section of the basement. Thr problem was all the crap in my basement, it amazing the amount of crap in boxes one can collect. So how do we kill 2 bird with one stone...sell all the crap in boxes and buy the tools and supplies your need!!! So armed with craigslist and ebay my goal is to fill the and finsh the shop with out coming out of pocket. Here we go...

Now I have alot of tools but I am missing the "Big" tools

Band Saw

Planer

Jointer

Table Saw

Router Table

Air purifier

and dust control

Now one of the things it will have ontop of tools and work space is a "spraybooth" Something that is sealed and vents out side so i can control dust and not choke to death on paint fumes.

here is the begining...dark open and raw..and a mess and this was after i "cleaned"

Now while this is going on I have been ebaying my youth and cleaning out boxes and making orders to fill the shop. I'll let you know what i get as i set the room up.

I framed out the walls that were just concrete and framed out the paintbooth and the room for the dust control and aircompressor. which is also where the furnace is.

As you can see the first "free" purchase is in the the Rikon Air purifier (oh how i love black friday sales)

Now one of the big issues was a) the lack of room in the box for electrical expansion

the need for 220. So a sub pannel had to be added. So that was the next step adding in a 100 amp sub panel.

the need for 220. So a sub pannel had to be added. So that was the next step adding in a 100 amp sub panel.

Lets turn that drill press into a pro buffing station..transformers

in Tools and Shop Chat

Posted

Hockey is always the best distraction.

What that is on the pulley that was orginally attached to the spindle, is what was going on the arbor of the buffing wheels. The inside diameter of it 1/2" but it needed to be 3/4" So I had to either turn down the arbor or bore out the pulley. Went with latter. Does that make sense? sorry sometimes my brain does not explain things very well