-

Posts

425 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Osorio

-

-

Yeah! I had my christmans tree setup!!! lol!!

I try to polish everywhere I can put my fingers on, but some edges are impossible!

I'll try with a dremel cotton pointer to night.

-

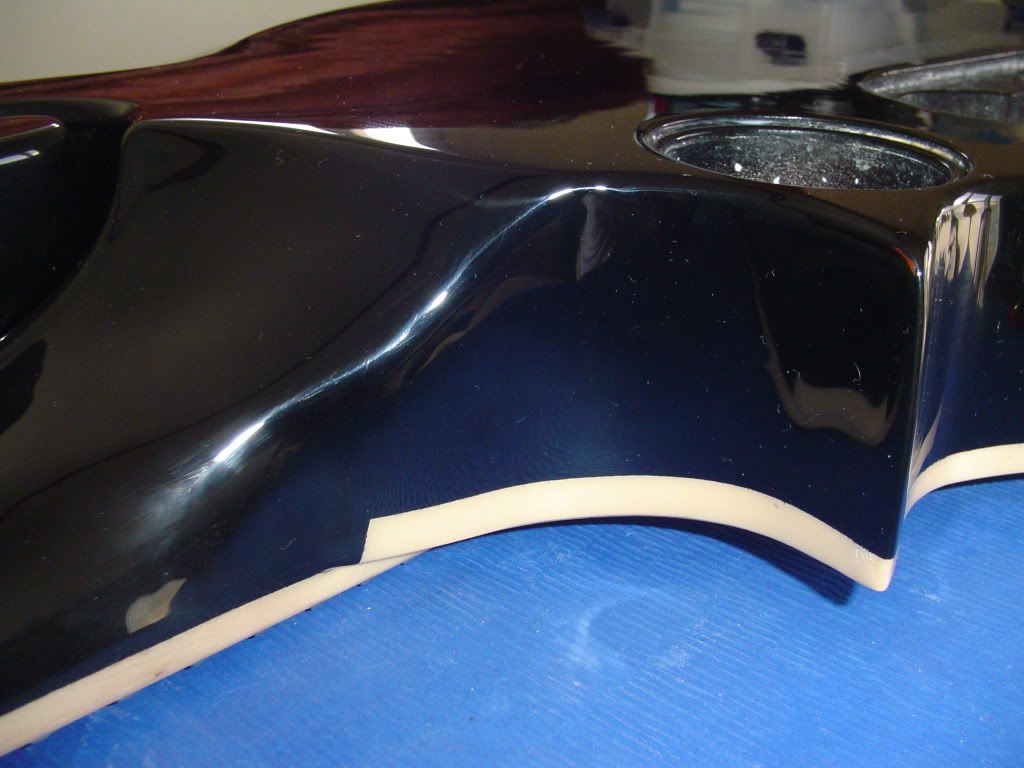

Now its almost finished!!

I had to refinish the back, owner wants to be black one!

-

Icemans are my favouite guitar shape, my main guitar its one of then.

I keep looking forward this thread, nice and clean CNC job!!!

-

Tks Fernando!

The maple came from USA.

-

Almost done!

Sand and buffing missing.

-

Res, I think that I already asking you about the epoxy, but I can't remember.

I keep following your threads and you have using epoxy in all of them. Most of then that I see.

How about the mechanical resistence of the glued line with epoxy? Into a neck joint for exemple. Why not use titebond? Wich are the benefits of epoxy instead vinylic glues?

Every epoxy glue that I have used, even "dry", keeps a soft surface, if I press my finger nail it marks. But I don't clamp any glued pieces, guess that makes all difference.

By the way very very nice top!! Keep follow!

Osorio my friend you are using the wrong epoxy. System 3 T-88.

I do not use 5 minute epoxies from a hardware store as most of them are not strong enough.

So I was turned on to System 3 T-88 by a couple of the guys here and I have to tell you it is very very very hard. You will not press a fingernail into it. I think I have a video somewhere of me slamming a cup of it against the concrete and it bounces really high with a tight resonant crack. I have glued several test boards together with it and beat them against the concrete with results identical to titebond (breaking somewhere other than the joint). One other good thing is that T-88 does not go bad (titebond that has frozen or is old is not good for anything).

I am a proponent of titebond and I build 90% of a guitar with titebond. However titebond and really oily woods do not produce a bond on joints as strong as T-88.

I use titebond for my neck laminates, body glue ups, most tops and headplates.

I am planning on testing West Systems Epoxy more this summer (harder to use because it must be measured precisely).

Officially I use T-88 for most fretboards and some neck joints (if it is not super tight) and oily tops/headplates.

Use more clamps. I have posted several articles explaining how you should clamp joints to get proper coverage.

And of course

http://www.titebond.com/Download/pdf/HowStrongisYourGlue_FWW.pdf

Here are a few other articles to read

How to Glue-Up Joints: Different Woods Need Different Clamping Pressure - Fine Woodworking

How to Glue-Up Joints: The right number of clamps - Fine Woodworking

How to Glue-Up Joints: Tips on gluing - Fine Woodworking

Of course I knew you did not use an ordinary epoxy glue, I would be roockie to think so (LOL).

Only reported my little experience with epoxy (5 min) gluing little things, where there was not great resistance mechaninc required only to show that I had no experience with epoxy in fact.

I thought the cure of the epoxy was shorter than the vinylic, and produce a stronger joint, increasing productivity and quality at the same time, but you have reason to use epoxy only for oilier woods. Nice articles, it's always good to remember things and learn others!

About the switch problem, I also thought of a blend/balance control with a ordinary pot.

-

Res, I think that I already asking you about the epoxy, but I can't remember.

I keep following your threads and you have using epoxy in all of them. Most of then that I see.

How about the mechanical resistence of the glued line with epoxy? Into a neck joint for exemple. Why not use titebond? Wich are the benefits of epoxy instead vinylic glues?

Every epoxy glue that I have used, even "dry", keeps a soft surface, if I press my finger nail it marks. But I don't clamp any glued pieces, guess that makes all difference.

By the way very very nice top!! Keep follow!

-

Tks all you guys, in fact that scrool or voluta take an special atention in all steps of the work!

-

And three additional sunbursting operations to get to this point

:

:

Not exactly like the pictured finish, it would require darker rims, but I kind of like it better this way.

Man simple awesone, killer one!

-

Nice thread Avenger!

I had learn a lot of wood working with my dad when I was a kid.

My son (3yo) take the same way, when I said that going to the shop he gets crazy to go with me. Some times I take he with me. He takes hammers, drils, saws, wood blocks and try to "make something".

In fact he put your little fingers in every where and I can't work just cary of him. (LOL)

But I feel that he likes a lot of tools, and spend time at shop, when he get older certainly will make some wood working, a guitar maybe (I hope).

-

Purple Painted

-

both colors are awesome!

-

-

It's a good tool in general.

I love mine too but There some things that could be better, the axis lock system to change the bit router, have a plastic cover that breaks faster, and the table lock system that if you are using a big router bit you'll have to adjust the lock pressure manualy. Router Bit vibration makes you lose the depth adjusts.

Today I din't bougth it, bougth an column router.

Someting like this:

-

Tks Maggo!

-

Prostheta - in fact the marks are both, excelent tip yours, I'll use. Tks!!

The spiral its a sticker easily removeable to change or keep nothing!

-

tks machado!

-

Tks Jax! The phat cats sounds great on the gutiar! I'm very suspect do say but .... LOL

-

Tks Fire!!

In fact it's a MM dressed of warbeast and it sounds great!

Brasilian Cedar gets darker sounds good to a bass body, Grapia/Guajuvira (maple/rosewod respct. substitutes) gets a brigther contour.

-

Now it's finished!

I alredy knew Dr Strings Red Devil, but here in Brasil are dificult to find an very expensive.

-

Assembly begins!

With new look finish!

Still looking for red or black strings

Someone try to paint bass strings with a thing coat of paint?

-

I forgot to ask, how about the tuning stability with bigsby?

-

I can't wait to see this two girls painted!!!

Nice Nice Nice BlackDog!

-

In fact I'm not a pro, I'm a hobbyst builder and get a lot to learning yet.

This guitar is a challenge to me, it's diferent of all guitars that I have made.

Every build have your teaching quota, this one had yours.

See youu guys!!!

Osorio - F5 Lespaul

in In Progress and Finished Work

Posted

A little, Wez, this porject gets me crazy!