-

Posts

94 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Zack

-

-

I always like to work out all details before I start a project. I am about to start a Tele with a 1/4' maple cap and I decided to make it a set neck because I hate the Fender neck joint with a passion and want a comfortable heel. My plan is to route the visible part of the neck to the usual spot and have a "tenon" extend to under the neck pickup hidden by the pickguard. It will be 22 frets so there will be a bit of fret board overhang. Also the neck will be natural color while the body will be tobacco and vintage yellow. I've made a workflow list and would greatly appreciate if anyone would like to critique it. The first 5 are inconsequential to the critical flow that I need advice on. I've included a pic I found that comes close to the neck joint I want. Thanks in advance!

Telecaster workflow:

- Setup band saw

- Build router table

- Modify neck pocket on template

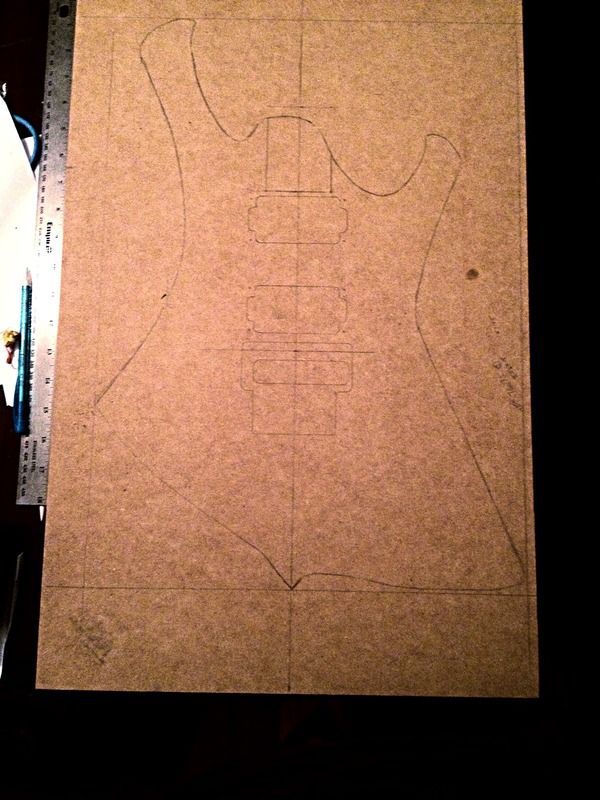

- Copy templates in ½” MDF

- Create 2nd set-neck pocket template

- Thickness plane body blank to 1 1/2"

- Measure and trace templates

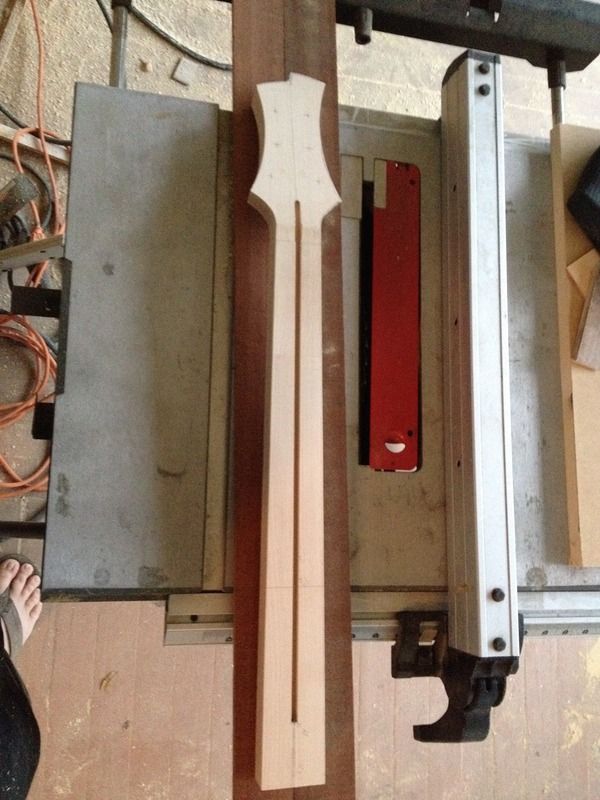

- Route truss rod channel

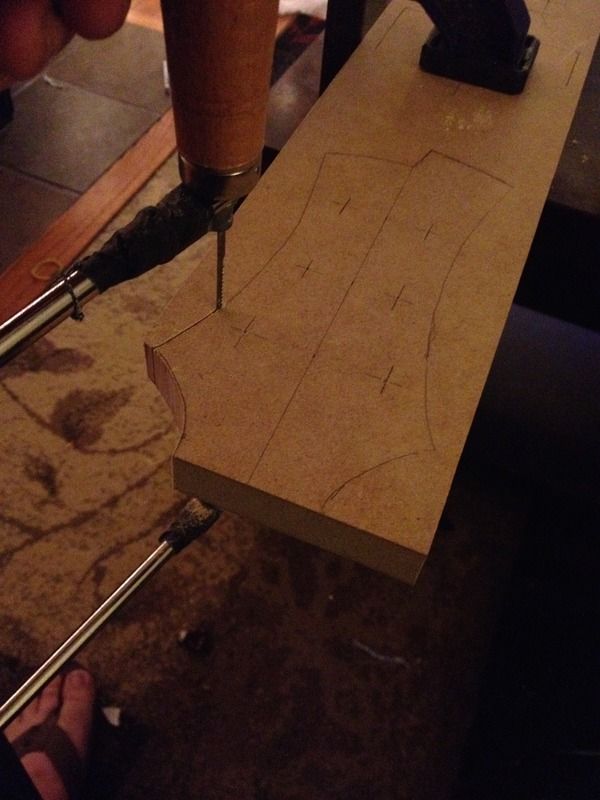

- Cut out shapes with band saw

- Route neck and body outsides with templates on table

- Drill tuner holes

- Drill headstock hole for truss adjustment access

- Glue maple cap halves

- Glue maple cap to body

- Route neck pocket and neck pickup

- Clamp neck to body

- Carve neck and carve neck joint

- Level neck tenon with body

- Glue fret board

- Route fret board to neck

- Inlays

- Sand and level fret board

- Dye fret board (Ebony)

- Stain and seal neck

- Route body cavities and drill jack hole

- Stain and seal body - Faux binding

- Glue neck to body

- Install and level frets

- Install nut

- Lacquer, lacquer, lacquer

- Wet sand, polish, and assemble

-

My Gawd! Those are all amazing! Do you hand carve all of those bevels?

-

This may or may not be helpful but I use Photoshop to design by placing a half-transparency existing guitar(of similar type) on top of my design and tweaking where necessary. Just make sure the necks and frets line up. I have a design for a LP style that looks a little goofy in scale but when compared to a real LP it's dead on. I did that same thing with my first design and an Ibanez RG. I had to do some major tweaking to the drawing I started with and scanned.

-

Very nice! My RGT42 is my all time favorite guitar (that I didn't build). If you get some extra dough just wasting away, the Edge Pro is a huge improvement. Love the valute work. A neck feels naked to me without one.

-

I'm pretty pumped about this one! I have new tools for this build including a 14" bandsaw, spindle sander, and router table. The last one was mostly done with a palm router but it got the job done. I'm going to throw a bone to North Ridge Hardwoods for sending such beautiful wood to work with. It's always such a pain searching for a good deal on nice wood when you are a newbie.

Alder with 1/4 maple cap

Flamed quarter sawn maple neck

Ebony fretboard with abalone top and side dots

It will be a standard Tele setup other that the truss rod (HotRod)

-

Very nice! I start my tele project Monday.

-

It took a bout 60 hours with limited tools. That includes building templates for the body, neck, headstock, neck joint, and pickups. The laqcuer is a different story. It was very cold most of the time and my impatience caused me to have to re-finish it three times. That was over 2 months of headache. It's still not perfect but it just put it together anyway to see if it was worth more effort. The good news is that it is an awesome guitar if I do say so myself. I've had a lot of great feedback.

Yes definitely and awesome guitar!! I have limited tools also and knowledge. I have been teaching myself the whole way. ScottR and the other guys on this site has been a big help giving me advice and tips.

If you haven't already done so, I suggest two great YouTube resources that cleared up a lot: Fletcher Handcrafted Guitars and Sully's Guitar Garage. Both do a great job of showing methods and beginning to end projects. I spent countless hours absorbing this info. It was worth it for sure.

-

The concept is good but the body just looks a bit small by about 20%. Of course that just my opinion. I will say that the point in the bottom is real trouble when it comes to sanding and finishing. You might make it a bit wider to give yourself a fighting chance. I did a similar thing, but larger, and it was more work for sure.

-

I've had mine in the bathroom for a few years. Maybe that was the wrong move? At the time I posted this a new one is $999 and a used around $100! ***?!

http://www.amazon.com/dp/0953104907/?tag=mh0b-20&hvadid=3482612920&ref=pd_sl_7acm9cfelw_b

-

Big fan of that neck! Got any rear shots that show the heel/body transition?

-

Looks Great! How long did it take you? I am working my first built and estimate to be done in Aug.

It took a bout 60 hours with limited tools. That includes building templates for the body, neck, headstock, neck joint, and pickups. The laqcuer is a different story. It was very cold most of the time and my impatience caused me to have to re-finish it three times. That was over 2 months of headache. It's still not perfect but it just put it together anyway to see if it was worth more effort. The good news is that it is an awesome guitar if I do say so myself. I've had a lot of great feedback.

-

It only took 4 years to get up the guts to do it but I did it and couldn't be happier (except for the crappy lacquering). The headstock was a last minute redesign. I've already ordered everything for a second and designed the third.

-

Is there some sort formula to roughly figure out the amount of surface area required to have a strong neck joint? I'm not really interested in LP style tenon joints although it will be a LP style design with a PRS style maple neck. Here is a rough draft of the design. I might add a fret or two.

-

Sounds like the way to go then. Thanks!

-

So if what you say will work, can I coat the entire guitar with satin, tape off the neck and finish the rest in gloss?

-

Here is my Photoshop mock up

Here is where I am:

-

I'm going to do a fabric topped Ibanez RGT42 neck through. I want the top and back to be gloss but the back of the neck to be the smoothest satin I can find. How do I pull this off?

Example:

-

We all know Stewmac is expensive in the tool department. I'm looking for some cost saving alternatives to a few items:

Radius sanding beam - $125

Japanese Fret Saw System - $109

Fretboard leveling files - $108

I can spend the money and don't want to cheap out on junk, but are there less expensive but equally effective alternatives?

-

-

Is it safe to share my design image here?

-

Wow! Thanks fellers. Dijonnaise huh? I'm fat and I love spice! Sounds like a winner. Actually Sriracha is my go-to flava o' choice with a little Dave's Ghost Pepper added for good measure

. It was a trick question. Went shopping for tools today. Couldn't find the spokeshave at the ole Depot. I picked up some rasp files and was eyeing a Stanley surform. Surform or rasp files or both. Hmmmm....Like I said, a billion questions. I love the suggestion of building a pine mock-up. I also plan to start on some MDF templates. Hopefully that will give me some usefull practice as well.

. It was a trick question. Went shopping for tools today. Couldn't find the spokeshave at the ole Depot. I picked up some rasp files and was eyeing a Stanley surform. Surform or rasp files or both. Hmmmm....Like I said, a billion questions. I love the suggestion of building a pine mock-up. I also plan to start on some MDF templates. Hopefully that will give me some usefull practice as well. -

Hello! I'm Zack and I'm a guitaraholic. Haha! So over the last month I've been indulging in information overload in the quest to build my first guitar. I've sold all of my camera gear which (after buying the wife some house improvements) leaves me with a budget of around $1,500. I've read Melvyn's book and I'm ready. My woodworking skills are OK but the tool vault is slim. Out of the billion questions, the top few would be:

1: My guitar body design is bigger than the standard 20x14 inch blanks available. Where do you buy bigger blanks? Google has not helped.

2: I've designed a custom trussrod cover to match my headstock. Cut one myself or have one made? Where?

3: Titebond I,II,or III?

4: Which is easier: Thru-neck, Set-neck, or Bolt-on? I like all of them equally, so personal taste is null and void.

4.50: Mustard or Mayo?

Thanks for your time!

Need some critique on set-neck Tele workflow

in Solidbody Guitar and Bass Chat

Posted

No, I was planning on the gap between the fretboard and body and the full width of the neck was going to be extended. That's where I was running into issues on what to do when. If the standard neck pocket is enough for a secure bond then that saves a lot of headache and I can just glue the neck right before I spray lacquer.