-

Posts

324 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Vinny

-

-

Hello Dan,

2 highly recommened books to have,

Lots of what you requested is covered in here:

Melvyn Hiscock's 'Build Your Own Electric Guitar' see Amazon for a copy.

Do a search here on his name and you'll have lots to look over, He also stops in now and then.

-And other book covers just about everything on wood finishing questions:

Flexner's Finishing Wood, here's a thread where I reminded members:

Take care, Vinny

-

I hope I'm not late to the party, but I came upon this tonight and thought it was a cool idea. A Stapler like Punch that die-cuts most plastics into a guitar pick shape. The website shows old gift and credit cards being punched up.

-

I spent some time completely re-doing the small desktop CNC Mill and Im finally beginning to see some results. This is a huge but fun learning curve. I re-sized my full scale guitar cad drawings down to mini size to test cut on the little table. They included mostly 335 shaped stuff like body, headstock and 3 ply neck lams. Thanks for looking, -Vinny

-

Hey Drak, good to see your stuff here. Beautiful work on this one, I especially like the binding choice and headstock design, very classic. I always admire the level of work you turn out, then I recall you have no 'big shop' to build in and modest tools. I walk in your shadow my friend. Bravo !!! -Vinny

-

Then God steps in .... he he. Thats a great side note, divine intervention ?? -Vinny

-

It sounds better if its not referred to as a commission, more like your building for your relative which Im sure a lot of people here have done. The 'C' word sounds like you're in business. Parts at cost and a little added on to get you into your next build is my suggestion, not $1500. I also recall the '10' thread having great advice and ideas. Good luck -Vinny

-

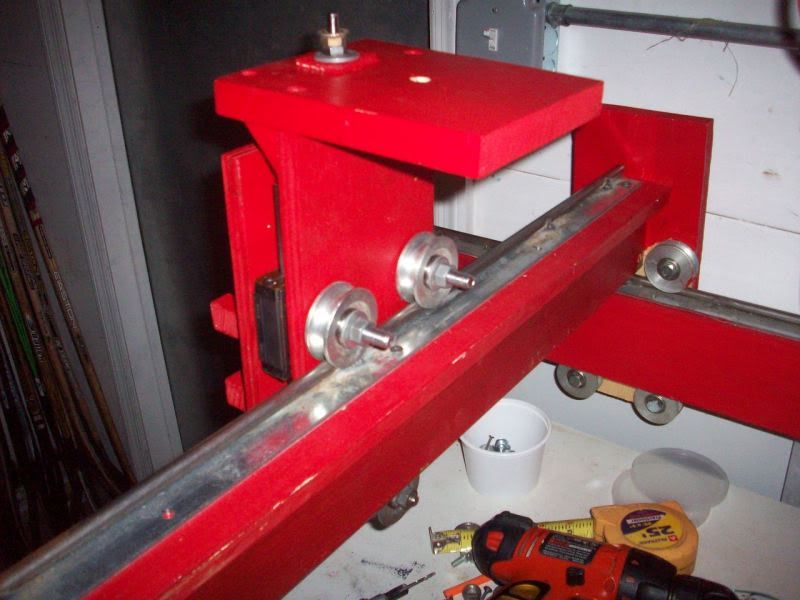

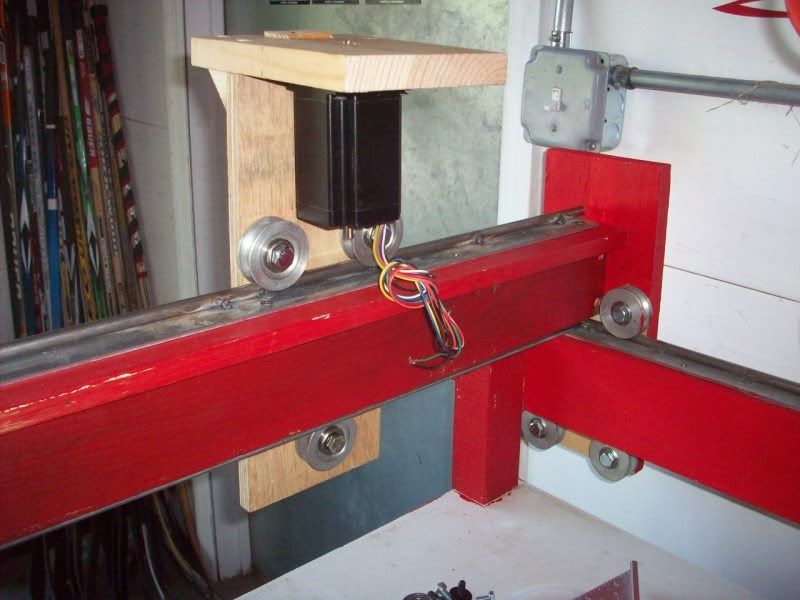

Came home tonight after watching local Fireworks with my family. The paint had dried on the Z axis so I took out the tools and assembled it. Heres a couple pics. -Vinny

-

I shelved the desktop CNC for now and I'm back working on the shop 24x36 Table. The red paint really put new initiative into the build. It looks purposeful now. The Z axis is coming together, I re-did a couple of areas and Im happy with how its coming along. Gonna place the order for the 4 belts this week, 2 twins for the long axis, 1 to go across and a mini for the compact Z axis. The rest of the parts are here, ready to go. -Vinny

-

Looks great John, I cant wait to see this one finished. -Vinny

-

Wow, that sure is perty ! -Vinny

-

FWIW, I've purchased from GuitarHeads and was pleased with his prices and service. We put together a package of hardware I needed for 2 Tele builds that worked out well for me, pickups, bridges, tuners, string trees etc. I will buy from him again. -Vinny

-

awfully slow John, Im pulling the garage apart now that the warm weather is here to better organize the work area. And re-sawing a bunch of lumber into usable sized pieces. I really got out of hand by accumulating too much stock. I have enough to build with for years to come. I calculated the ideal size for neck blanks, sides for bending, center blocks and tops and backs. Then marked up my rough boards for cutting. I should post a picture, its like that show here the States called "Hoarders"

-Vinny

-VinnyYour build is inspiring me to get back to my hollow body. I miss the feel of dried Titebond on my fingers, and the look of my kid's faces when I peel it off and watch their reactions, very funny.

-

great old saying that I'm trying to piece together, heres the basic jist of it:

"The apprentice will make a mistake, not realizing what he did.

The Journeyman realizes his mistake.

The Master Craftsman makes a mistake, he hides it perfectly or it become part of the overall design."

-Vinny

-

Can you post a link to the jig you mentioned, Thanks, -Vinny

-

Looking nice Crow, whats the plan for a finish? Stain or clear to show the wood? -Vinny

-

Update:

My desktop is project is stalled. The parallel X pulley set-up I used to keep the gantry from racking needs tweaking. The motor and lead screw in the pic are diagonal and pull a nylon rope that runs a continuous X pattern moving the gantry from the sides equally.

Im re-locating the motor/leadscrew to the traditional front to back layout but will keep the X pulleys/rope in place for its accuracy. I had things running good, after I extended my

Lead wires to the motors I was back to jumpy steppers and wrong steps. Will try Mach on another computer to see if it helps. -Vinny

-

Spoke, sorry to hear you had problems, the new set-up should be Sweet !

Mike, I too read that post on OLF and thought like you did, your reply was on target. "Here's a freebie" and you get blasted. Theres a few cool open minded people there but it can get like MIMF at times. Oh well.

-Vinny

-

Take it as a lesson learned, re-finish it and move on. Builders here have stripped off a a finish they weren't happy with and started over. It depends on your idea of whats acceptable. I happened to learn this while reading Melvyn Hiscock's book, he shows squeeze-out while gluing up a set-neck and has a damp cloth at the ready to clean up the ooze. He mentions that finish/stain won't adhere to the glue and will give poor results. Bob Flexners's Finishing book goes further and recommends a scraper to ensure all glue residue is gone. Thanks Bob & Melvyn

Ive made mistakes all over the place while building, its part of learning. The tools are usually not the problem, WE ARE !!

-Vinny

-Vinny -

-

Heres a sketch John, I thought the silver -grey could be MOP and the Bolt done in some kind of gold material. -Vinny

-

Cool find, it appears over here in the States too! A smaller version though -Vinny

http://dogbytecomputer.com/gardman-r687-4-...greenhouse.html

And Amazon too

http://www.amazon.com/Gardman-Rainbow-Gard...e/dp/B000NCTGQE

-

I powered up the board today and ran the motors as they sat unmounted on the desk, basically I watched in amazement as the motor shafts air-cut a basic circle with the test file I made. I threw my fists in the air and let out a big OHHHH YEAHHHHH !!!! Then the Kool-Aid guy crashed thru the wall and smashed all my hard work.

Big thanks to Mikro for helping out a fellow PG'er -Vinny

Big thanks to Mikro for helping out a fellow PG'er -Vinny -

I converted an old power supply from a computer to work with the desktop CNC. I was amazed at how straight forward it was. I probably could have spent $8 on the whole thing but I got fancy with a illuminated on/off rocker switch and extra LED's and binding posts. I salvaged a old steel VCR wall mount box and added a front panel to finish it off. Total, just under $20 spent. -Vinny

-

Very Cool John -Vinny

Real Gold Top Les Paul

in In Progress and Finished Work

Posted

Cool, this gives me some ideas for a replica motorcycle Im building comprised of parts from the late 1920's and 30's. Most of the pieces are rusted and weathered and the issue of making a faded and worn brand name on the tank was unsolved till now. This would be a great look for the bike. Thanks ! -Vinny