Setch

-

Posts

2,494 -

Joined

-

Last visited

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Setch

-

-

Just cleared off 50+ spam posts from the OT board - should make things a bit easier to navigate!

Don't know what the solution is to stop te spam, but a few more deputised regulars couldn't hurt.

I noticed there was one spammer who did like 5 of the same posts today. Usually a spammer only does one post and hits the road.5? I wish. Make that 35!

-

Neato. I'll run a dumb terminal and a USB port to my workshop

Looks like a very nice way to perform fine adjustments, but more involved to machine than I fancy. Looks like I'll stick with the quick'n'dirty adjuster when I make up my bender.

-

I can see how the offset adjuster works to adjust the radius, but how do you adjust it? Back of the nut a little, then move it around and re-tighten?

Sorry, I think that by trying to frame my question clearly, I answered it. Oops.

-

Didn't I see a jig somewhere where you could make your own with your router on a pivoting arm? Someone should make up a dozen or so and put them in the "for sale" section. If they resonable cost, I would purchase one to save me the trouble to building the jig.

-John

Found it!

http://www.projectguitar.com/tut/radius.htm

I went to google to find it, and it sent me right back here. I should have known.

-john

I've actually just made up a newer version of that jig, which holds the router upright, and keeps the radius block level. I've cut one block, 9.5" radius, about 24" long and it worked out well. I'll bank that it has *way* more than .016mm varience, but I don't look for that kind of accuracy in my radius blocks - they just radius. A carpenters level does the levelling afterwards, as well as imparting a slight compound radius by sanding parallel to the strings not the centre line.

-

Is this a guitar you have made?

Why do you need to remove the neck?

Many classical guitars are assembled without a head block. They use a "Spanish foot", which means the neck is one continuous piece, including the headblock. If you need to adjust the neck angle (ie: perform a neck reset), on a classical this can be accomplished with the use of a tapered shim under the fretboard, or by slipping the back.

-

And your guitar body will of course be more stable and steady compared to ANY block of ANY species of ANY age wood you put in there.

Why?

If you choose a piece of the same species, well dried and seasoned, and with the grain oriented correctly, there is no reason why your guitar would be more stable and steady than your repair.

If you're going to use block capitals to stress a point, best make it correct.

-

That would be stocking...

Must be a bummer leaving Todd's shop, I get the impression he'd be a great guy to share a workspace with, and a great source of info and experience top have on tap.

-

Given all the fuss people make about tight neck joints, and removing the finish of the neck heel etc, it always surprises me when people stick a small shim in a neck pocket, thus massively reducing contact area.

I machine tapered wedges out of hardwood, these contact the whole of the neck pocket, and all of the heel of the neck. IMO this improves stability, and whilst I'm not going to claim I can hear a difference, it certainly doesn't hurt the tone, so I feel it's worth the extra effort.

-

Whilst the problems are worrying, I can tell you in advance what Stew Macs responce will be;

'There's another one in the post, no charge. Sorry for the inconvenience'.

They have a justifiably stellar repuation for making it right if they drop the ball.

-

Lovely design, and perfect execution too - can't wait for a shot of that inlaid and levelled!

-

Looking pretty sweet - love that blackwood!

-

You don't *need* to curve the slot, but a curved slot will make for a more responsive trussrod. You can use a straight slot provided it is below the centreline of the neck all the way along it's length.

If you use threaded rod, be sure to cover it as described earlier with insulation or plastic sleeving, or the threads will bite into the neck wood, and prevent the rod sliding smoothly in it's channel.

-

Strings tuned to pitch.

Read the neck (ie: do you want more relief, less relief) and push the neck gently into the position you want. The best way is to lay the guitar down with the body supported and a padded support under the end of the neck. Push in the middle of the neck, and then tweak the rod (small adjustments - 1/8th at a time) until you get the result you want.

Doing it this way, the rod isn't having to move the neck, it's just taking up slack to hold it in the position you've introduced. I find the neck settles faster this way too.

-

If you spray a nice wine red back you'll dissapear most of that. You'll need to use tinted clear *not* stain if you want to disguise the patch, if you do this it should look if not invisible, then at least extremely inconspicuous.

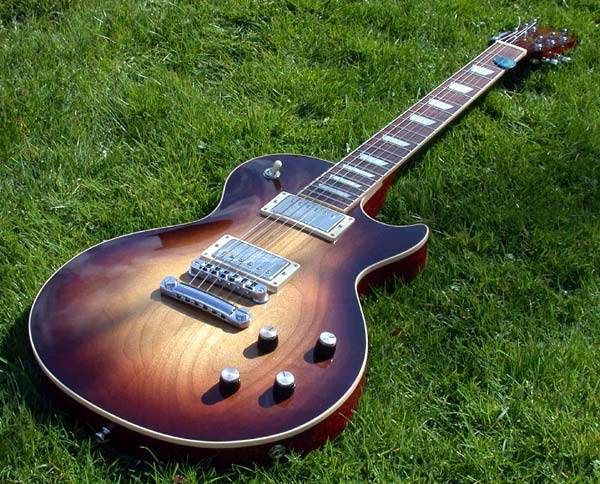

I think you're probably thinking of John Silver's LP, which looked great, but I also sanded though the burst on mine, and had to hide two nasty dings from dropping it on a concrete floor mid-finishing, and it still turned out fine. Noone can find the repairs except me, and I have to look very hard!

-

Looks good. Keep an eye on the nuts and bolts whilst using it though - this kind of jig is very likely to suffer from vibration, and the nuts may creep loose and allow the angle or height to change whilst you're working.

-

Whilst recessing the bridge would get your problem solved, I'd say you can go for a less drastic solution. You bridge studs are still a good 2-3mm above the guitar top, and could easily be sunk flush with the surface, either by counter boring the top of the guitar, or by turning the shoulder off the stud in a lathe. I think if you did that, you would bring the action down into perfectly acceptable range, and save yourself the aggravation of routing a slot, and touching up the poly finish.

Also, check neck relief and adjust the trussrod first - my Les Paul had action well over 2.5mm at the 12th fret with the bridge bottomed out when I first strung it up. I was gutted, and convinced I'd bodged the angle somehow, until I checked the relief. My (flatsawn mahogany) neck had bowed like crazy under string tension, but a tweak of the trussrod later, and it was all fine. I ended up having to raise the bridge as the action was too low to dig into. The neck hasn't needed adjustment since.

-

I saw this on the OLF - very nice, but I agree with others about the pickup trim rings. I always find pup rings which deviate from standard dimensions very distracting, and these really grab my eye, which should be focusing on the rest of the (beautiful) guitar.

If the routing will permit it, I'd go with some standard size rings, keeping the maple theme. If you're not keen to machine your own (they can be a bit fragile - DAMHIK!) you can get curly maple rings from Stew Mac.

-

Egg-zackerly.

Take it back , and tell them it's wrong.

-

-

I'm not quite so sold on the other repairs in the thread - I'm not a fan of the use of splines, which really don't make much mechanical sense. In the case of the Gibson V repair they're almost certainly detrimental to the strength of the joint, which was a text book example of a 'long break' which will be as strong as before with a good glue up, not to mention almost invisible.

RFR's repair on the ther hand is a stunner - great finish touchup, and without a doubt far stronger than the original neck - A back strap is a far superior method in every respect. IMO splines are only ever appropriate on short breaks or re-breaks, and even then I think they are suspect - you get no clamping force in the direction you need when they're glued in, and the amount of gluing area they add is minimal.

-

Nice job!

-

I suspect you're searching for a solution to a problem which doesn't exist - as evidenced by the countless millions of acoustic guitars with domed tops which are doing just fine. Besides, a top which is stressed so it wants to pull flat is probably no bad thing, given that it's being pulled on by strings trying to make it go the otherway...

-

I wouldn't use splines, they really don't help, and simply remove wood which would otherwise be soundly glued. This guitar is a candidate for a back strap, as it's a fairly short break, without many long side grain areas to glue together.

This is a pretty major procedure, but it's the right way to do it if you want it to last.

http://frets.com/FRETSPages/Luthier/Techni.../phoverlay.html

-

Oh, and just to add - he can't have one face flipped wrong, or the pieces wouldn't mirror like that.

He might, however, have the whole thing upside down - ie: he's looking at the front and back cover, not the centre spread

Glue Strength Question

in Solidbody Guitar and Bass Chat

Posted

A good joint means one which fits well, so that all surfaces are in contact, and no gaps or voids are present. For many joints on the guitar, which have lots of surface area (like a scarf joint or joint the in a two piece body) this simply means getting both surfaces perfectly flat and smooth, so that you get a very thin glue line.

Generally speaking, it's better to have a simple joint which fits pefectly, than to have a more complex joint with gaps. Glue itself is very weak, but the bond it creates between 2 pieces of wood is very strong. If you have a badly fitting joint you'll get a thick glueline, and a weak joint.