t1r12003

-

Posts

270 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by t1r12003

-

-

-

Looks great dispite the sinking finish. I'm still debating on stain or natural. The yellow adds some nice tones. Thanks for sharing.

-

-

Killemall8, that's beautiful. What was your staining and finishing process?

-

-

Just a heads up, unless you really seal the crap out of that redwood, it will sink into it forever. It is like a sponge. Even after epoxy and 2k clear, it still sunk into the shape of the grain on my last guitar.

Thanks, I'll keep that in mind and spend plenty of time sealing it. I just finished a buckeye burl top project and it was the same way.

-

-

-

-

-

-

-

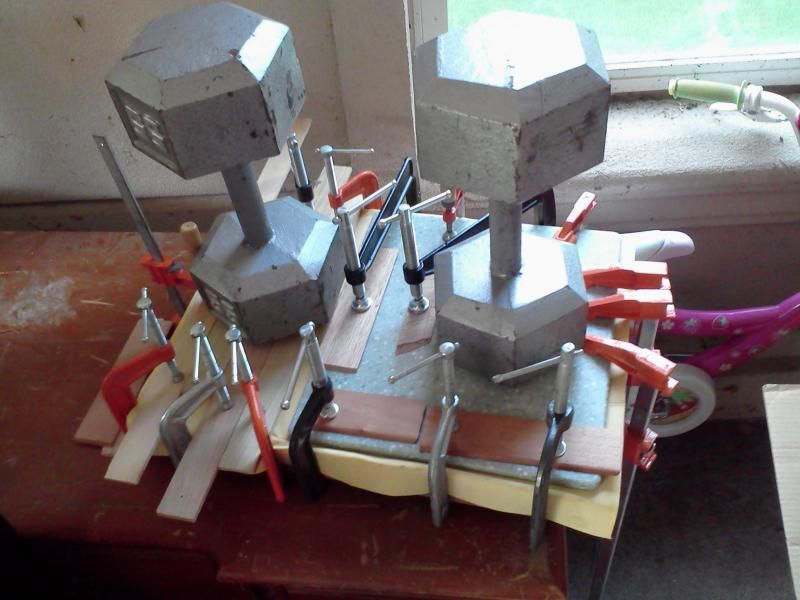

All finished up spraying. In total, one can of sealer on the whole body, one can black lacquer on sides and back, one can clear on the top and a second can of clear for the whole body.

I'll let it cure for 6 weeks then wet sand. Hardest part is the waiting game.

-

-

-

-

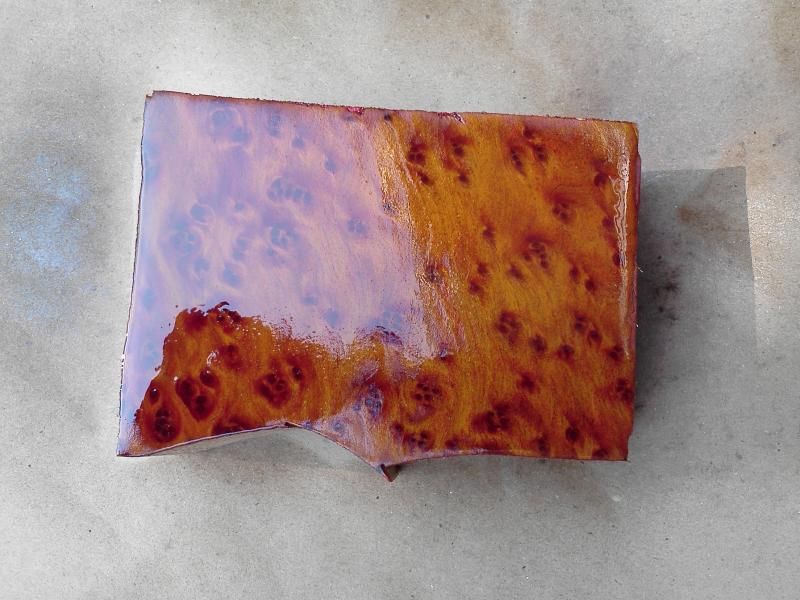

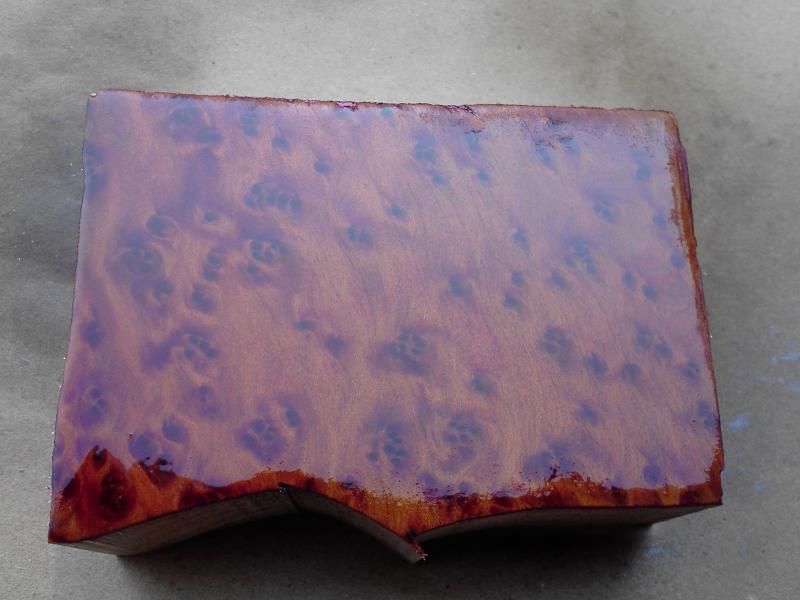

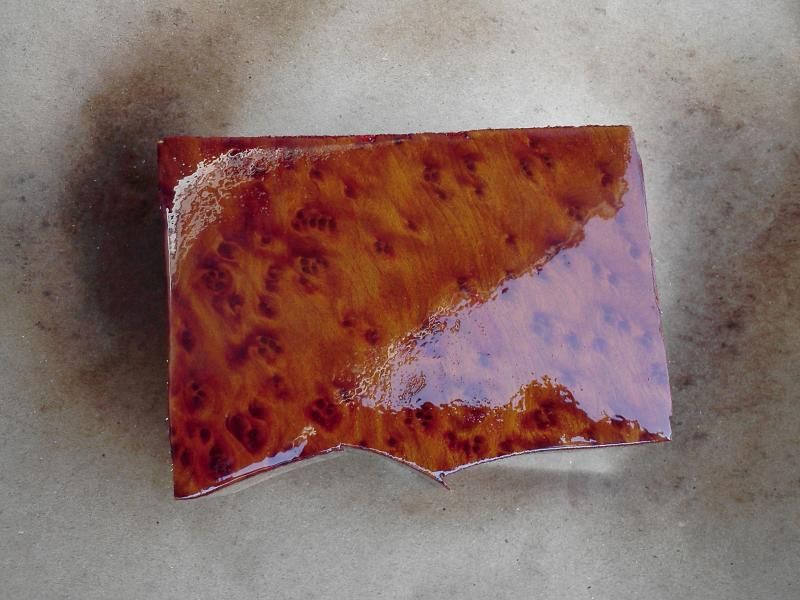

Sanded back the body with 400, wiped down and repeated. Back and sides look great, super smooth. The burl top showed quite a few pinholes that still haven't soaked up enough super glue. Went back over all those spot and flooded them again. I'll let the superglue cure and sand smooth again and see where I'm at.

-

-

-

-

I know, I can't believe I started this back in Sept 2012. 2 years in the works. Life has a funny way of getting in the way of projects.

-

Well, it's been a long time, but I finally got back to this project.

More pore filling of the buckeye burl top with super glue to make sure there are no holes or voids anywhere.

Routed and drilled holes for the 3-way switch, trem posts, and volume knob.

Next up is final sanding of the body, then grain filling the mahogany to prepare for spraying the back and sides black and clear coating the top.

-

1

1

-

-

The alternative to dyeing is to shoot a tinted lacquer. That would avoid issues with dye not taking to areas sealed with CA anyway. Does your Maple need it though? I am not one for using dyes on figured woods as they tend to flatten the natural chatoyance/movement of the figure. Great for "popping" figure by darkening exposed end grain.

You might still want to fill the pores of the Mahogany with CA however it can be quite unforgiving when sanding, second only to sanding epoxy. There are plenty of grain fillers out there that are easier and less poisonous to work with than large amounts of CA flashing off over a large surface burning your nasal and eye tissues with the fumes....

Apologies if I missed the point of what you are doing. Kind of sidetracked.

No worries. CA (super glue) to seal the natural burl, no stain. Regular mahogany grain filler for sides and back.

-

It's still sitting here almost done, like 20 other almost-finished projects, haha!

Yes, the first coat of whatever type of finish you're using seals the pores of the wood up against any following coats and at that point, the wood is sealed.

There is no special product that seals wood pores better than another, it's just the first coat of whatever it may happen to be.

The primary purpose of sanding sealer (which I think is a little silly myself, but others quite like it), is to make sanding easier by adding soap to the lacquer, which, btw, makes the laquer softer overall if used to excessive amounts. That's it. I myself never found straight-up lacquer that hard to sand, so I never use it.

Remember if you're going to wipe the whole surface with CA to fill up the soft spots AND you're going to dye it that you really need to sand it back really well so you don't get blobby spots where the dye couldn't get through the CA glue and get straight to the wood, which it needs to do.

Sweet build, I love it.

Thanks for the tips. Before I started with CA glue, I made the decision it would be natural.

Laced Redwood Jazzmaster

in In Progress and Finished Work

Posted

Yeah, there was seepage in the center line, but not too much. I just haven't taken the time to sand the glue spots out yet, but when wet you don't see them. The top looks so good natural wiped with Naptha, I'm still not certain I'm doing a stain at all. The test pieces I used with red, brown and yellow and the black and yellow piece are subtle.