-

Posts

5,635 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by Bizman62

-

-

4 hours ago, Frans said:

Do you also know why my maple retouche pencils and fillers show me a total different colour (red/brown)?

Fillers are homogenous stuff, they don't have the translucency of wood cells. Also, they're thoroughly coloured and as such they only can show one shade of the vast palette of colours seen in real wood.

If there's just a scratch on the finish of your fingerboard I wouldn't use any filler, instead I'd use tinted lacquer even if there's some wood missing. That would show as a scar as the cut fibres would suck the finish but you'd get the surface level. The only place I'd use filler is a deep small scar, like if hit with a screwdriver some 5 mm deep. A small spot filled with light coloured filler and finished with tinted lacquer might blend in. Any bigger wounds would be better filled by cutting a bit larger piece off and trying to fill the gap with another piece with a matching grain pattern.

Regarding birch filler/colour, I wouldn't use any wood coloured filler with clearcoat. I've seen my share of natural coloured furniture that look OK when new but after a few years the wood darkens because of daylight but the filler stays pale. It may look decent when stained but not as natural.

If you could post a photo of the damage it would be easier to tell which option is best.

-

Hi and welcome aboard!

Maple is a blonde wood as such. Even if it's figured the figuration is pale. The basic colour is a tiny bit yellowish so it's not cold paleness. Birch is close to it, so much that it's sometimes called poor man's maple. Maple also takes dyes well although for a cool blue guitar you'd better choose a piece as white as possible so the natural yellow in the wood won't turn it green.

Your fingerboard is naturally pale but the finish/lacquer enhances the red and yellow pigments. The lacquer on old strats also darkened in daylight and as "everyone wants" a vintage instrument they may add some amber dye to the clearcoat. And of course the wood itself gets somewhat of a tan in the sun.

For fixing a scratch that shines white on the yellow fingerboard I'd mix a tiny drop of amber dye with clear lacquer, apply thin layers until the colour matches and finish with clear. Try to find a piece of maple or birch for testing the colour before applying it. Or at least test the colour-clearcoat mix on a piece of white paper if you can't find a piece of wood.

If you wonder what the original colour was when the guitar came from the factory, look under the tuners! That will tell you how the finish and wood have aged.

-

Your rough carve already looks very playable!

-

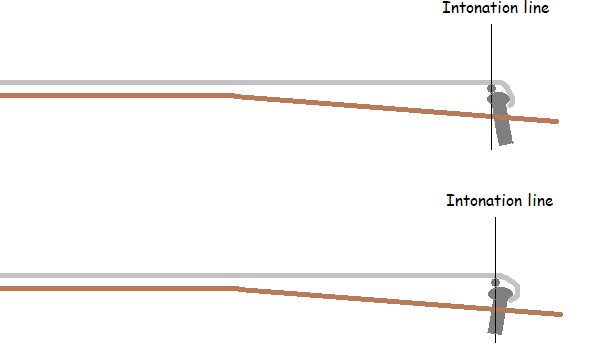

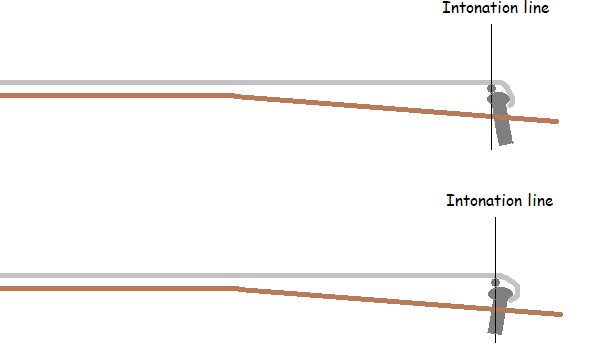

Looking at the picture @henrim posted made me think of a known issue with wraparound bridges, i.e. the stud holes potentially becoming oval at some stage. It's a minor issue and may not become serious during the life span of an instrument but it does exist.

Now if the bridge is at a 90 deg angle to the strings and there's a steep neck break angle, wouldn't that pose a risk of the posts being slowly pulled out? Again, a minor issue but obvious when looking at the lowest exaggerated sketch.

But if the studs were vertical to the body, wouldn't that mean that they should be closer to the nut? The strings meeting the bridge at 87 or so degrees may not be any issue as it's the edge that matters.

-

Ahh, of course. Flat surfaces, silly me.

-

1

1

-

-

Keep us informed about how it goes!

-

Absofreakinglutely gorgeous, then again that's what I was expecting.

One question though: The golden control plate is inlayed but the bridge plate isn't. Why the difference?

-

1

1

-

-

I've used Abranet also for wet sanding, it can hold lots of water and the dust doesn't roll over the surface that much.

-

4 hours ago, henrim said:

I’m not a Stanley man myself, but as I have understood they can be dated quite accurately by studying the casting markings and so on.

That's true only for Made in USA Stanley planes, those made in GB or Australia are more Frankensteinish regarding their details.

The video is interesting but as they say and stress at 1:30 you can only use that method on a clearcoated surface. The clearcoat of cars is most likely 2k poly or at least acryl/alkyd lacquer, not nitro or shellac. That said, as the handles already are "ruined" with the blue paint you won't be doing much further damage by accidentally stripping some of the original finish.

Three of my four Stanleys were made in England made so I wasn't too worried about saving the original crackled finish. The fourth one is a US made from 1925-28 but as the handles apparently weren't original I didn't care about saving their finish either. The story of that one: https://www.projectguitar.com/forums/topic/55200-restoration-of-an-old-hand-plane/?do=findComment&comment=635001 p. There's another restoration story by @curtisa: https://www.projectguitar.com/forums/topic/53060-stanley-handplane-restoration/?do=findComment&comment=596904

-

1

1

-

-

That can be a tough one as the old plane handles often were finished with shellac. And we all know that shellac works with most every finish available so the blue paint most likely is properly stuck. It would help a bit to know what type of paint that is to choose a solvent to remove it but as shellac dilutes to both alcohol and acetone those are mostly out of question. Xylene might work for the paint without reacting with shellac but you never know. Any chemical may remove more than you'd want to. If you try any solvent or paint remover, don't let it go through all layers. Instead be alert to flush the handles to stop the reaction when you get a start and go with elbow grease from there on.

The original finish might also be nitrocellulose lacquer as it became widely used in industry after its invention in 1921.

So scraping might be the best option at least when it comes to detail work. A plastic scraper might be gentler than a steel one, they even make razor blade type scrapers out of plastic but any piece of plexi should work.

All that said, at least the knob looks like there's no finish left on the top. Also in my experience the original finish tends to flake which makes it very uncomfortable to use as you can get a shard of it under your skin. Thus when I restored four Stanley planes last summer I removed the flaky finish and even used some solvents to get rid of the tiniest chips. I then used some sandpaper/abrasive felt to smoothen the surface, applied some dye to make the pale wood look like rosewood and finished with a few coats of my self mixed TruOil. Guess that's close enough to the original finish. Something I noticed during the process was that even after having sanded the surface smooth and clean the wood felt somewhat impregnated with something that didn't let the dye in. That makes me suspect that the handles have originally been treated with Boiled Linseed Oil or Tung Oil which has filled the outermost cells and sealed the surface. Or maybe even with their own mix of oil and lacquer because that's what Tru or Danish Oil is, BLO/Tung-oil mixed with resin (nowadays poly but originally resin from conifers) and turpentine. Anyhow, the wooden parts can't be peeled to reveal a flawless original finish as parts of it have worn off so refinishing is the best option if you're going to use the tool. The blue paint tells that the original finish had already worn off to the level of sending chips to your palms which also means there won't be much left of the water decal in the rear handle - if there was any in the first place.

Just so you know, the black stuff on the cast iron isn't paint, it's BLO and asphalt which has been baked on the surface. The same finish was used for T model Fords and Singer sewing machines.

-

1

1

-

-

23 minutes ago, MuriSan said:

That means tere's no reasonable way to do this.

Again I repeat myself: Take the neck off to see what the neck pocket looks like. If it's square, a Tele style neck might fit. If rounded, a Strat style neck might fit. They can be very inexpensive (~50) depending on where you buy them. For minor adjustments you can use shims. Then just cut the headstock off and attach the end block. All you'd need is a screwdriver and/or hex key and a drill. More importantly, everything you do can be reversed if you're not happy with the result.

Before doing that, figure out the fretboard radius and the neck profile of the Fender you like.

-

1

1

-

-

1 hour ago, MuriSan said:

Actually the idea is not to drop two frets but to have all that scale lentgh divided to 22 instead of 24. That would mean, all across the fingerboard the distance between two frets will be slightly bigger.

Doing that would ruin the intonation.

Think about the #1 rule of scale length: The 12th fret has to be right in the middle of the fretboard, no matter the scale. The position of each fret is based on mathematics: You divide the scale length by 17.817 for the first fret, then divide the distance between your 1st fret and the bridge by 17.817 for the second fret and so on until you've reached your desired number of frets. More here: https://www.liutaiomottola.com/formulae/fret.htm#12th2about

The pickups have nothing to do with intonation or scale length, they're just placed in the free area.

As I said in my first post here, the issue is in the neck/fingerboard profile rather than in the number of frets. You can test that by putting the Kiesel and the Fender face to face, nut against nut and each and every fret should match except the two last ones of the Kiesel. As you said, the radiuses are very different to each other, 20" is almost flat compared to 9.5. Also, Kiesel allows you to choose from three thicknesses of a C shaped neck. Fender has at least 20 neck profiles, many of which are available or have been used in Strats. Doesn't that make 60 different Zeus-Strat pairs? Which one matches your experience?

-

And the eternal saga goes on slowly but not so surely. One step forward, two back or so it seems at times. Anyhoo...

In the previous episode I flattened the end for the trapeze. In the meantime the sharp edges were rounded so it was time to redo the inlaying. Scribing along the edges went fine and a 12 mm gouge was close enough to match the shape of the ears.

But the wood kept fighting me! The wood is soft and brittle and somehow I lost the line and the other end and while finessing the edge the carve got too wide. Even after rounding the edges with a piece of sandpaper and blending the colour with some more oil mix the difference was obvious.

So I did the Jazz fix: If you make a mistake, repeat it so it becomes a feature! Cutting the other side equally wide added the required symmetry and the result doesn't strike the eye as badly.

So finally now that that issue was fixed it was time to attack the other end. The headstock veneer was originally added to bring the nut high enough to bypass the end of the fretboard. But as the headstock is slanted the seating point had to be flattened. The file has a safe edge so it only took a few strokes. The bone is now plenty tall but I don't think I'll carve a groove for it, instead there'll be some smelly filing in the near future. I like the Chinese acoustic guitar bone nuts, they're inexpensive compared to raw bone and have precut string grooves. They're tall and thick so there's plenty of material for shaping them just right for any purpose.

And finally it was time to start thinking about the eletrickery. Originally I was going to put the switch between the pots but after some discussing with fellow builders I decided that a reverse Tele would be a better choice. So the last hole was widened and the switch is now in. Sort of.

I thought I had the pots for this one already packed in the workshop bag but I couldn't find them. But it seems that I'll have to do some more routing, the top of the cavity seems to be too thick. Not a biggie but it will nullify the tape job.

The pots are now packed into the bag so hopefully next week we'll start to finally get there!

-

1

1

-

-

4 hours ago, ADFinlayson said:

The whole point of wanting a 22 fret neck instead of a 24 is that the neck is not as long,

So despite the scale length being 25.5" on both versions the 22 fret neck is shorter on a Fender? That would mean that the bridge would be closer to the end and the overall layout would be an inch or so closer to the bottom.

-

Hi and welcome! And holy necro bump!

Someone correct me if I'm wrong here, but if the scale length remains the same, there's no difference between a 22 to a 24 fret fingerboard other than the two extra frets that require moving the neck pickup closer to the bridge. From the nut to the 22th fret they should be identical. Same thing with a 30 fret guitar, the extra length is just eating the space where you'd normally put the pickups. Ibanez RG2011SG is a perfect example of that.

Thus your problem isn't the number of frets, it's more about the neck profile and/or the fingerboard radius. Replacing the entire neck would be the easiest solution as the Kiesel has a bolt-on neck. The main problem with that would be to find a neck that fits the neck pocket unless you do it from scratch. I mean, for example there's a difference between Strats and Teles despite being from the same maker, the Strat neck has a rounded end whilst the one of the Tele is straight. Taking the Kiesel neck apart might give a hint whether you could take a standard Fender 24 fret neck with your desired radius and just cut the headstock off. That might work within the intonation range.

-

1

1

-

-

Hi and welcome to the addiction!

Coincidentally I've built an LP Jr with a somewhat similar bridge, link to some pictures here: https://www.projectguitar.com/forums/topic/49819-guitar-of-the-month-july-2019/?do=findComment&comment=579304. The most accurate tool I used for measuring the scale was a 1 metre steel ruler with 1 mm increments which did the job accurately enough.

As far as I know there's nothing too different in measuring the scale length on a guitar with a neck break angle, the angle is so subtle that it doesn't significantly shorten the scale. A simple way to visualize that is to take a tape measure locked to 25" and lift it by half an inch (the height of your bridge) at the 12.5" mark. You really can't see the end move, that's how much it affects.

As the bridge has adjustment backwards you'd want it to be as front as possible.

If you want to get the intonation as good as possible, you can make a trapeze sort of jig of something like a clothes hanger or other stiff wire. Bend it to a V with eyelets for the ball ends of both E strings and hook it to the end pin hole. Tighten the E strings and lay the bridge with makeshift spacers where you think it should be. Measure the intonation and move accordingly, then mark the place. Something like that, don't forget protective padding:

-

4 hours ago, ADFinlayson said:

While that is possible, I think it's unlikely. The greyish look in the top is because there is still a small amount of blue in there too,

Can't you accept a rescue route when it's offered to you on a golden plate?

-

5 hours ago, ADFinlayson said:

Well. getting all this dye out is proving to be a real pain in the butt. It's pretty much only in the end grain now,

Are you 100% positive that it's dye? To me it looks similar to the discoloration caused by fungus seen in many pale woods. The vertical lines on the top seem to have similar bluish greyness in a number of shades.

-

Slowly but surely it's starting to get there. After once having seen someone inlay the jack plate it has been a detail I prefer.

Not too long ago someone told having spread some DNA on his build. It took me a while to figure out that it wasn't of this ilk:

The old pine seemed to be quite brittle around the hole so some solidifier was needed

And voilà!

Next step was the trapeze which looked like something that has been slammed on without proper planning.

So I thought the same recipe would fix that.

No, that plan wasn't going to work so I took it to the belt sander. Some rounding to blend the flat spot in is on the to do list. And maybe also inlaying the plate.

-

2

2

-

-

1 hour ago, henrim said:

it looked odd when I opened it in Illustrator.

Looked odd in my browser as well, I thought the sketchy looks was intentional.

-

9 minutes ago, antony said:

it would help me a lot to open it

For me there was no problems to download and open it. It's big so it took 40 seconds to download and 10 seconds to open with my Internet connection and PC.

-

Hi and welcome!

Regarding your first concern, I guess the post is appropriately placed but if it isn't the Forum Gods most likely will move it without issues.

The actual question may seem a bit more complicated, but it took only a few seconds to find answers like this: https://www.thespringstore.com/spring-finder.html

Remember, there's no such things as "guitar springs" or "guitar screws" or even "guitar paint", some companies just make living easier for people who don't think with their own brains!

Installing the spring... Well, the car repair shops use threaded rods with dedicated cups for the spring ends. Modified locking pliers might provide a similar tool for a trem spring. All you'd need is a tool that would compress the spring leaving the end loops free to be put around the studs.

-

There's finishes and there's finishes. Cellulose can be much softer than 2k poly. No wonder I got the 3M pads from a car paint shop!

Last summer I bought and sort of restored some older hand planes which led me to search for some information about the black finish on old Stanley planes. No wonder that the finish on them (and old Singer sewing machines and T-Fords) has been able to last a century: It's not paint! Instead it's a mixture of BLO and asphalt melted on the surface.

-

5 hours ago, ADFinlayson said:

I think Abranet is good at sanding wood, raelly good actually, it seems to skip over poly though

Exactly. My observations tell a similar story.

.jpg.7c299227e42cdbe080dc07d4b72c474c.jpg)

.thumb.jpg.11ddad44aa6793a2df739ec7001c3977.jpg)

.thumb.jpg.6b9adb73f2459bfadbc9f80d5801bb6c.jpg)

.thumb.jpg.e9780bef01804fe50ea3629c696acd17.jpg)

.thumb.jpg.adf848076095d3f3423ffb7c3008d208.jpg)

.thumb.jpg.972e5932de23e782e62a691a45d9d2b1.jpg)

.thumb.jpg.5719b684cfdecc69df948e771f77d093.jpg)

.thumb.jpg.e48ee446f2871dc2a2302cd370c3d982.jpg)

.thumb.jpg.a1503b767b858a1017ab91000ab192f4.jpg)

.thumb.jpg.980ea4119a831852d96cfcd4465e31c8.jpg)

.thumb.jpg.a0217d5685ca8b945714640afd96852f.jpg)

.thumb.jpg.ae124eca189bad41eefe9b9e7df8ff4d.jpg)

.thumb.jpg.b04d24fc4e6f512457ccad6f9b800ddd.jpg)

.thumb.jpg.2dccbf8c68116d7fbd3464d18d832fac.jpg)

.thumb.jpg.68943360c987bcbe9d0f9fc1c9a79e5c.jpg)

.thumb.jpg.07b45354de64cfe9933b452c6ef0ec08.jpg)

Sanding help!

in In Progress and Finished Work

Posted

Hi and welcome!

Yep, looks uneven to me. Did you use a block or your fingers when sanding? I've used poly only twice, the first time there was some humps and bumps but the second one came out perfectly level after sanding the orange peel off. Even the sides are almost flawless. But the guitars were flat so using a semi hard block was a no brainer. Don't know what kind of a sponge as a block would follow the curves but still only knock off the high spots.