-

Posts

4,759 -

Joined

-

Last visited

-

Days Won

133

Content Type

Profiles

News and Information

Tutorials

Product Reviews

Supplier Listings

Articles

Guitar Of The Month

Links and Resources

Forums

Gallery

Downloads

Posts posted by mistermikev

-

-

so was thinking about setting up to do a body join on my cnc.

I typically do it now using a 3" long 3/4" diameter cutter in my hand held router with a top bearing... yeah... it's a bit crazy. I generally am just barely taking off 1/32 at a pass but even that is pretty dangerous. I am careful not to choke the router and it does fine... but I'd rather just do it with my cnc if possible. It'd be safer and even if I just do an initial cut with the cnc it will even out the material right at the grain line I want it at... and worste case I can do a final pass with the hand held.

My cnc doesn't accept anything bigger than 1/4 bits. (no, not talking about 1 pass with the cnc.. this would still be .08" passes). In order to do this... I'd have to buy a longer bit. I also would need some bigger hold downs. So before I go spending money on this adventure... I thought I'd get any input you'd be willing to give. ever try it?

if I'm going ahead... I know that bigger diameter bits - the cutting edge is going faster... and with the momentum of the extra metal - they tend to cut better/smoother. That said... a sharper bit would leave a much nicer edge. My spindle can handle the bigger bits, but I'm not sure that's necc the way to go. I don't want to spend more than $40 on a bit and it'd have to be at least 2.75" tip to toe.

what say you? fools errand?

-

so... minor update here... I got my body chamber all figured out... the chamber is radius'd to the same arc as the top... so I'll be cutting the body in ash, then cutting the f holes in a top, then bending it over and gluing down, then cutting the pickup holes and neck hole... but this gives you the jist of the inside anyway:

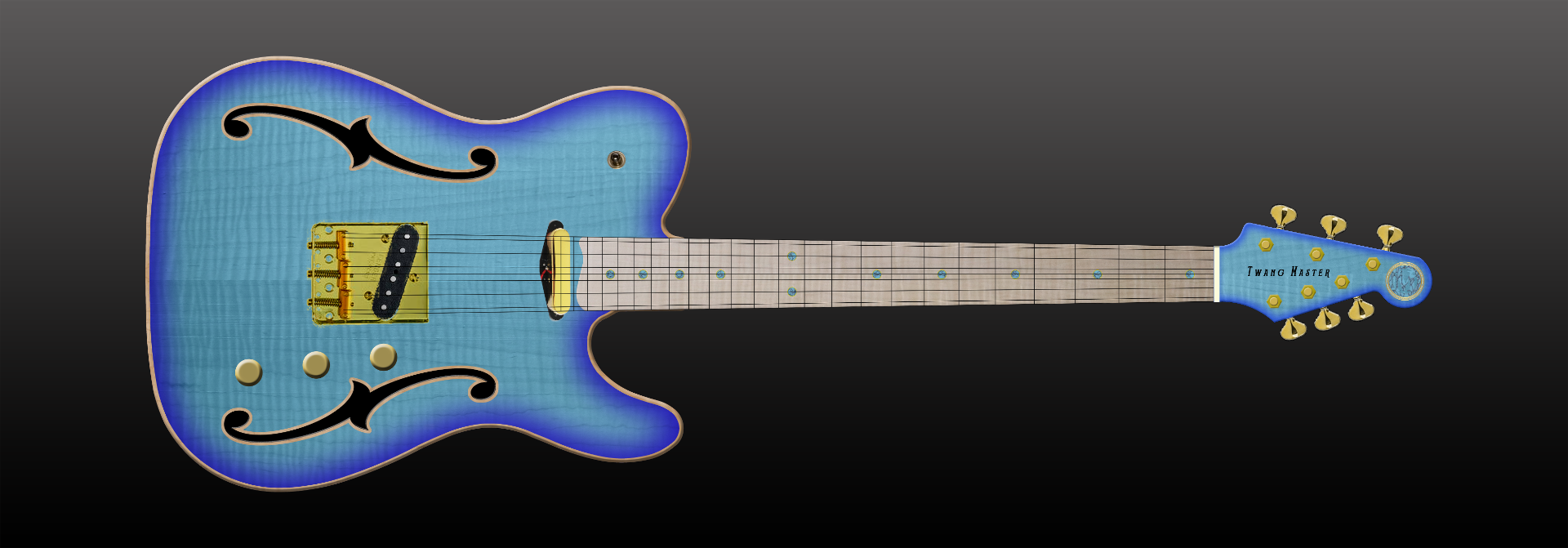

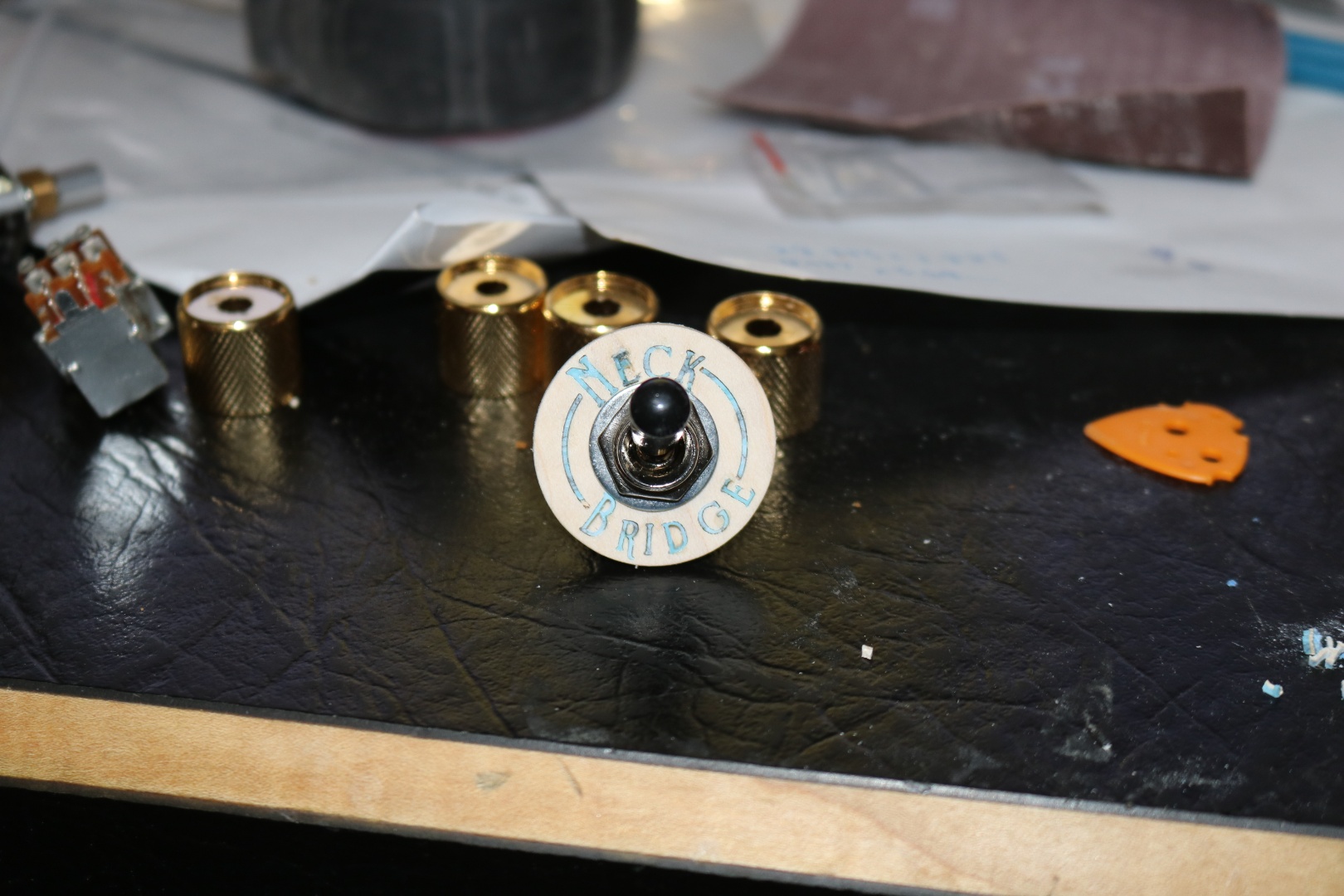

also, did a goto meeting with my friend and we hashed out remaining details like controls, headstock, and tuning machines. We also named it... was thinking "wang master" but since my friend has kids finally settled in on 'Twang Master'

so this is the final version:

-

1

1

-

-

13 hours ago, Drak said:

Happy to oblige, on the house this time.

You get one point (+) right off the bat for having a heightened awareness for noticing my psychopathy

.

.

What came to mind first was an agreeable-minded 'Can't we all just get along' personality.

The repeated 'I would say yes' is couched in a very agreeable way, so as not to create conflict.

(Of course I understand we're on a forum with rules and etiquette, I'm stating this as if it were person-to-person, which this is not).

So, the personality characteristic...The flip-side of that type of stance (usually) is conflict avoidance.

This doesn't work when the other person has no fear of conflict and will engage to win at all costs.

Purely goal-oriented, zero sum personalities (I will win, so you will lose) will steamroll right through a 'can't we all just get along' person.

And they are most definitely out there, and I kind of enjoy dealing with them when I run across them.

I am not conflict avoidant, nor do I believe in a zero-sum mentality.

I would also throw in (my healthy cynicism at work) that anything written by someone in the field with product to sell is marketing.

So anything they say that would promote their sales or their Image, I find heavily tainted (with taint) and would cast it aside as kompromat.

Nothing exists in a vacuum, and there is meaning behind everything a person says or does as a sum of their exported actions out into the world.

Most people just don't take the time to look for it or acknowledge the (usually obvious) meaning implied.

They want to keep their 'map of the world' intact, tho it may be a very outdated (and sometimes over-innocent) map that needs some updating.

So PRS, running a company-for-profit, venerating on guitar tone attributes, I chalk up to his future sales and personal public image enhancement.

And so wouldn't take it seriously.

Predatory? Possibly. Goals-Oriented? Probably. Image-enhancing? Definitely. So it's all about him in the end, not you.

This all taints the core information (for me) as indigestible.

On a funnier side-note...

Your paragraph where you pose the question then provide your answer made me laugh.

It reminded me (not implying you at all here, it just reminded me) of people who end every sentence in a vocal 'upswing'.

As if everything they say, they're not making a statement, but posing a question, even when they're making statements..

I was watching a YT a few months ago about car soundproofing where the guy did it every...single...sentence, for half an hour.

He is telegraphing to the world that he is extremely unsure of himself and has very little (if any) confidence in himself.

People who exude natural personal confidence either hold a very even tone or end sentences on a downswing.

That includes women. It cuts across all genres, ages, races, etc.

Like they're landing the plane with every sentence, not taking off. But it's natural, they don't even know they're doing it.

On the strangely opposite side of that spectrum...

This year, (usually on political shows), I have never heard people begin sentences with the word 'LOOK' like I have this year.

Like they all (recently, too) went to the same marketing promotional school or something.

Used sporadically and naturally, it can be effective and evokes confidence in the listener that the speaker has confidence in themselves.

But when it is used to start every sentence (and I have heard it done) it becomes obvious that it is being used as a (cheap) manipulation tactic.

And then, to me, makes the person look like a complete moron for not being able to formulate their own clean sentences.

It elicits the exact opposite effect they were trying to achieve, that they don't have confidence and need to rely on 'gimmicks'.

Now about those 21 tone tips...

well, in your defense I DID encourage you.

-

I actually have a saw stop. My brother and mother bought it for me as I had mentioned that I wouldn't buy a tablesaw because they are the most likely candidate for accidents. The thing I didn't expect is how nice of a saw it actually is. the fence/blade came true out the box. you can test wood to see if it's too wet by turning on power (not power to the blade) and touching the wood to the blade - if the light goes out - too wet.

I'm told that you can't put a thin fret slotting blade on them as the mechanism won't work. There are some thicker blades that will work.

having worked in the cabinet industry for a bit when I was younger... you can't help but notice how many 'old timers' there are who are missing a digit. Go to your local woodcraft and chances are someone there can give you a look at reasons to be really careful.

all that said... even the saw stop will shoot a board at you with enough speed to kill so... still have to know that machine before you mess w one.

-

1

1

-

-

well, I won't miss the opportunity to get analyzed by a psycho so... here goes:

I often think about things in relative terms. so... it seems it is generally agreed upon that the wood plays a significant role to the sound in acoustics... and it is generally more contested on solid bodies. So I think "at what point does an acoustic become an electric?" In other words... if you take an acoustic... and start adding wood... where is the crossover point where the "tonewood" starts to be inaudible? Similarly... how much wood can you remove from an electric before the "tonewood" becomes significantly audible? just a thin guitar? a thinline? 335 style hollowbody with a solid wood center block? full hollow like an es295?

I don't believe it ever 'stops' mattering... it is just less and less a significant part of the total makeup. so it matters, and to what degree... well who cares because even if it's .00001% that is going to matter more or less to each person.

further, pickups... sure they are magnetic... is magnetism influenced by materials around it? I think so. further, lets disregard that... is the vibration of a string influenced by the presence or lack of material around it? I would say yes. Is it influenced by the density and rigidity of the material around it? I would say yes. is the strings own vibration influenced by the reflection off of said material? I think so.

again... is it significan't? well that's a matter of opinion/taste/perspective - so in my mind there can be no right or wrong... but I would say that it would be hard to argue that it makes zero difference.

conclusion: If the vibration of the string is influenced, and that vibration of the string in turn influences the resultant disturbance in the magnetic field... seems reasonable that the type/density/rigidity of the wood has some sort of influence on the sound of a guitar. (I know... really going out on a limb here).

I would now like my free evaluation as promised.

going to go read up on prs 21 rules... there is some amount of truth in everything... even if the author has a vested interest in the sway... so will see if I can find those slivers there.

-

the fact that you created that in paint... kind of bumps it up a notch for me! lol. nice work. i hope those purple areas are meant to be purpleheart reveals.

think you might want to mock up your tuners because it looks (to my untrained eye) like you'd need a bit more real estate to get the machines on there w/o issues but i could have no idea what I'm talking about (full disclaimer)

nice job on the design.

-

1

1

-

-

On 12/24/2020 at 9:50 AM, komodo said:

Have never done woodworking before, but was summoned from the depths so I'll take a stab....

Consider that even if you had a deformed plank, you are slotting it and hammering metal bits in that can very easily warp it in the opposite direction, Then you are applying an adhesive on a large surface, essentially laminating it to the neck. You could probably use any material on the planet really.

Never done... u r silly. I dunno... not sure unky spalted maple would be a good idea, but I smell what yer stepping in there.

8 hours ago, Prostheta said:I used to be far more diligent and obsessive over things like flatsawn vs. quartersawn years back. Exactly what Mikro says about Fender, agreed. My more chilled out (more, not "completely") self thinks that symmetrical growth ring direction across the neck profile is key. Also, avoiding wood with tight growth ring radii as these will always be the greatest source of movement and warping in service.

When it comes to visual aspects, yes, you can't avoid specific cuts if you're trying to show a specific figure available only on that cut. Birdseye spots off the flat close to the outside of the tree for the most part, flame off the quarter, etc. I stand by my premise of using good wood (larger growth ring radii, symmetry) rather than obsessing over quartersawn-only for neck shafts and whatever for the fingerboard. Hundreds of thousands of perfectly serviceable necks in all camps of thought reduce the need for overthinking ring orientation! Do what makes you happiest with your work as long as the basic rationale is good.

So... more symmetry than absence of runout? I guess it hadn't occurred to me that symmetry was something to look for but now that you said it... seems obvious! Good call.

1 hour ago, ScottR said:My first fretboard was a flatsawn piece of bocote. And as pointed out earlier maple is commonly used flatsawn. I believe it was @verhoevenc that pointed out some years ago during a similar conversation that maple actually shows greater stiffness when flatsawn......and also pointed out that this is an anomaly inherent to maple and not true of all or even most timbers. @komodo got it right I think. If it will hold frets and is hard enough to resist wear from playing it will do for a fretboard, however it is cut.

SR

This is going in my trick bag... maple is more rigid if flatsawn... that is a jem!

Sorry for ignoring your posts after I called yall out... rude of me. I am enriched by your knowledge and am very thankful for the responses!

-

little update... got my 'real' run off the cnc... spent some time with my dragon rasp yesterday... she needs a whole lot of sanding and some details worked out... but getting there...

got a little bit of wavy gravy on the underside due to not smoothing the transitions between several arcs... and a little 'brithmark'. will have to decide if I want to do the work to smooth it out or chalk it up to 'character'.

-

2

2

-

-

guitar there looks great... love the stylings. excited to see some purpleheart... it is fastly becoming my absolute fav wood. that 'swirly' wood there is lovely too.

hss - right on. I need to do a hss... such a great combo don't know why it sort of fell out of popularity.

looking fwd to it!!

-

build is looking great. really great.

if I may... and this is NOT meant negative in any way - just... the pickguard... the one half of it looks A+... but the bottom half... in my humble opinion... you should re-work it and make it follow the lines better. in my humble o... it's one of those details that can really make or break a guitar.

again, the guitar is looking really great, and I think a little change there would go a long way - just one aholes 2 cents so don't take it to the bank.

rawk on.

-

first off - glad to hear you are feeling better!!

"i love the smell of tools from stew mac in the morning" (hehe, heart of darkness).

welp... that's a think I do... just wondering if it's catching on or if you accidentally hit the p??!? hehe.

looking fwd to build pics

-

looking great. that camo would be noice.

-

I have one on my es295 as the bigsby was pulling it out of tune w std saddles... but that guitar has an archtop bridge so... doesn't really answer your question but it is angled. Personally, I would def angle the studs because that way if you ever decided to go to something else it wouldn't be a problem. just my 2 cents.

-

-

so... a lifelong friend of mine, who happens to be a cop... has been asking me to build something for him for a while. I'm gonna do it despite being nutz deep in my bass builds. should be a nice way of saying 'thank you for your service' anyway, and tele's are a lot of fun so... this is my placeholder for that adventure.

talked him into letting me get a bit experimental so... doing a complex radius... sort of a bell curve between 12r and 30r. this is the guitar I think I'm planning to do a bookmatched fretboard on... probably do a radius back and thinline with a radius hollow area.

here's what I have so far...

this shot here (below) is my best attempt at capturing the transition (or lack thereof) between the neck and neck pocket. It has come to my attention lately that what feels good to me afa upper fret access is all about the thumb. With that in mind... I carried the profile of the neck right up to hilt. it looks like it would be less comfy as there is not much transition... but it actually feels really good and I think I'm going to expore this some more going fwd.

-

1

1

-

-

18 minutes ago, gpcustomguitars said:

Yes, I'm also a fan, but just not the 30'' ones, they lack a bit of clarity, at least the ones I tried. The warwicky one I made for my friend is 32'', I like it's playability a lot.

couldn't agree more. strings flop around pretty good on a 30 and it feels like a toy... but two inches bigger and 'perfection'.

-

1

1

-

-

9 hours ago, MiKro said:

I have used birdseye before, No problem. Now think about Fender. They used flat sawn boards for necks with a skunk stripe. Think about what I just said.

mk

hehe, literally took the words out of my mouth. I was saying the sm thing a couple sentences back (fender) because that occurred to me. if it's good 'nuff for them!

thank you for chiming in!!

6 hours ago, curtisa said:You big tease.

For the record, I'm not saying that any old flatsawn piece turned 90 degrees makes it quartersawn. There may be legitimate reasons why a truly quartersawn piece from a log would behave differently that I'm not aware of. But thinking about it in my rattly old head there doesn't appear to be much difference between the two. Another way to look at the interchangability between flat vs quarter, if you were to grab a layers of flatsawn stock from the log slicing operation, the slab that ran dead through the middle would be quartersawn at the edges.

Properly quartersawn timber is expensive in comparision to flatsawn because it's wasteful. If you were to genuinely quartersaw a log into fret board shaped chunks, you'd have to rotate the log around its axis and cut everything in a bicycle spoke wheel kinda pattern. Dividing the circular log cross section up into rectangular chunks radiating out from the centre means that you can't maximise the usage of the whole log, as the wedge-shaped space between each rectangular piece gets thrown away.

I'm trying to, but I keep on coming back to chocolate. Ommmmm...Nope, there I go again...

i read that whole post.... but what I have to say about it is - such a fan of david mitchel! smart guy, and super funny. mitchel and webb look... I gotta go speed watch that again!! again, thank for your insight!

3 hours ago, Bizman62 said:Having read every word above it's obvious that different species act differently. As I said in my first post my experience is from pine flooring where there's both slab and more or less quarter sawn planks. Maple is much more homogenous. Further, as the birdseye feature is caused by tiny knots that never grew there's no single grain direction, just swirls and curls all over the place.

for the record... was just mentioning birdseye because I read that it was only flatsawn and found that interesting. I'm interested in using flamed maple... which is much more prone to warp/cup/bow. yeah, doesn't really make sense that it'd have to be flatsawn... but I always default to assuming I have no idea. thanks for the reply.

3 hours ago, Andyjr1515 said:Well, talking from the point of someone still struggling to see a piece of wood and tell if it IS quartersawn....

But when did that ever stop me pontificating...

I think it's more to do with cupping of planks. The narrower the plank, the less this is an issue, so for a small square section, like a neck blank, it isn't really an issue. Beyond that, I think it's more about aesthetics.

very much appreciate your perspective.

-

55 minutes ago, curtisa said:

Zounds! What on earth makes you think I'm some kind of expert?

Although, I'm kinda tickled that you'd think such a thing. Silly you...

Although, I'm kinda tickled that you'd think such a thing. Silly you...

I've used birdseye maple for a fret board precisely once. I don't recall anything particularly unusual about its properties or working that made me think I'd never use it again or do something differently next time. Maple is an imported species for me though, so I don't use it terribly often.

You got me curious enough to go to the workshop and check my modest collection of fret board stock. It's generally a mixture of flatsawn and quarter. The only piece that looks appreciably warped is an old board (flatsawn) I steamed off a failed neck, and I'm willing to bet that it looks the way it does because I wasn't being gentle trying to get it off, rather than it due to being flatsawn in the first place. Another piece I have is essentially a flatsawn piece of decking timber, a portion of which ended up on a build I did some time ago that has ended up having the most stable neck I've done to date. Make of that what you will.

Based on the above very small anecdotal evidence maybe you could theorise that the original milling orientation of the log matters less compared to how well it dried? Flatsawn may have a tendency to cup and warp more as it dries, but once it reaches that equilibrium is it any more stable or strong? Dunno.

I suppose you could even argue that if you took a flatsawn maple post with a 3" x 3" cross section, there's nothing stopping you rotating the post 90 degrees and sawing off your fret boards and calling the resultant pieces quartersawn. Afterall, the growth rings are no longer running parallel to the wide, flat surface of the fret board and are now perpendicular to it, which is pretty much the definition of what quartersawn stock is.

I deeply respect yours and many opinions here... so much so that I will frequently listen to what you have to say... I mean... it's a pretty low bar because you just have to know more than me! haha! Seriously tho... group knowledge isn't always stronger than individual knowledge... but solid individual knowledge peppered with group knowledge is ALWAYS stronger than almost any individual knowledge... at least in my experience.

and you came through... because I hadn't even thought to go check my stack of fretboards... and there are indeed some qtr, some 'sorta qtr' and some flat sawn. one of the flat sawn is twisted a hair... and it is birseye. despite that I'm inclined to think flatsawn would be fine as long as you cut it, seal the edges, let it sit w both faces in contact with air... and give it a week or two to move.

I think you are right about the dry thing. thinking about it... fender necks were always one piece and flatsawn. Given a choice between two identical pieces but one qtr sawn I think I'd go qtr but I don't think I'll shy away from flat at this point.

my mind exploded reading that last part... so... eep... oop... bla... does not compute. I get it tho... even qtr sawn is only relatively qtr sawn as grain is never perfectly perpendicular. that said... as you get further and further away from perpendicular grain... there is more tendency to move albiet maybe fairly mitigated in well dried and seasoned wood.

-

1

1

-

-

so I've read around a bit on mylespaul, thegearpage, acousticguitar forum, few others.... from what I have read it is not at all uncommon. I guess birdseye is ONLY flatsawn so... any birdseye fingerboard you see is flatsawn. At this point I'd like a couple more opinions to either dissuade me or push me forward so I'm calling you out: @Andyjr1515 @MiKro @curtisa @ScottR @Prostheta @komodo and whatever other devil's will be summoned - what say you?

-

3 hours ago, Bizman62 said:

Yep, quarter sawn is much harder. Slab sawn will peel by the growth rings as shown in the image below:

The darker wood is the denser winter wood and the softer summer growth will both wear, dry and compress away.

hmm, did not realize this property of flat sawn. I guess it makes sense... stack of papers flat vs stack of papers on end.

-

I'm 6'1" and 250lbs... but I LOVE short scale basses! they just play and sound so great! this is gonna be a cool build.

-

1 hour ago, Bizman62 said:

I haven't done flat sawn fretboards but I know how flat sawn flooring wears and that is not nice. Agreed, pine is softer than maple but we're not wearing shoes upstairs where our bedrooms are. Several splinters have found their way through the socks since the Osmo oil wax wore out in places like in front of the toilet or in the kids' room.

interesting... you are saying quareter sawn wears different? I had not considered that. Honestly have zero wear on the fretboard of any of my guitars... but I imagine folks with long fingernails have more of an issue with that. Something to consider anyway. thanks for the reply.

-

45 minutes ago, Bizman62 said:

For pushing gently you can use the drill press as well.

that's a good call. the one with the nipple is actually pretty close to the edge so.... might spare my drill press and just use a clamp but it's a good idea and will keep it for reserve. thanks for that.

-

so... have this long time friend of mine - he's a cop. been asking me to build him something for a while and I've given in... least I can do to thank him for his service. So... one of the things I thought would be cool would be to use the sm material for a top as the fretboard and headstock overlay. I'm going to use birdseye for the actual neck - some really rock hard birdseye so that should add some serious rigidity to a 25.5" scale neck. I have some 3/4" x 12" flamed maple that he likes... so was thinking I'd resaw it for a top and have enough left over for a fretboard and headstock overlay. I'm half considering bookmatching the fretboard cause I think that'd be really cool... to just have it bookmatched all the way up the neck.

I am aware that typically fretboards are made from quartersawn materials, and while I'm sure someone has done flatsawn... just wondering if any one here has any experiences doing that and what they learned from it?

I imagine one stumbling block is - you don't want to resaw it and have it sitting around too long - way too prone to bend/cup/twist. Other pitfalls you can think of?

so... cnc body joining?

in Tools and Shop Chat

Posted

all good points there. I think I typically do 80ipm but still that take a fairly long time. That said... I have a camera and can spend that time at my pc jacking around with other things. Further, if I was going to do it regularly I could setup a jig I could just mount and fire off.

is it worth it - yeah, probably not.

the bit length... currently my bit sticks out 1 5/8" and I've used all of that without issue nor noise. Literally had her up to the hilt and hand on the stop button in case there was still one pass left!! I would just need to get to 2" of cutter below the collet but I like to have my bit at least sticking out of the back side of that collet a little bit.

further.. I don't know if this is crazy talk... but was thinking that if I do one pass in .08 increments... and had a bit with 2" of flute... and then moved my x by 1/64"... I bet I could get a pretty solid join. Any mistake would be certain disaster tho so... I dunno.

thank you very much for your wisdom sir.